This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Las espumas microcelulares reducen costes y pierden peso"MuCell", patented by Trexel, technology is a standard procedure for the manufacture of special Microcellular foam

Microcellular foams reduce costs and lose weight

He is not a new system: the pieces foam in its entirety or in the core manufactured with moulding machines for injection are a common practice for many years, and will again be present at the upcoming 2004 K. Conventional integral foams have have followed the so-called Microcellular foams, a new generation of foam that allows to save material and, therefore, weight and costs.

Engel machines have a special injection unit for MuCell.

Integral foam injected, both conventional and which have a Microcellular structure are in fashion. Thanks to them the polymeric components are lighter and use less material, which can bring a competitive advantage that allows them to expand their share in a highly contested market to transformers. Applications, both the existing and potential, are focused primarily in the sectors of the automotive, Aeronautics and the construction of vehicles. But they can also have application in other areas, such as electrical and electronics industry or sector of appliances of white line (inner washing machines, dishwashers, dryers, or chest type coolers).

Two basic variants of thermoplastic foaming can be distinguished: the physical foaming and chemistry. In both types dissolves in the first place a gas in the molten mass of plastic and secondly, as a result of the subsequent fall of pressure, produces a thermodynamic instability to enable the formation of foam. Both variants are different in that, in the chemical foaming, the gas is generated from the decomposition of expansion agent integrated before the molten mass, while in the physical foaming gas is injected in mass melted at very high pressure.

License for foaming

The most common are currently Microcellular foams. In other words, are those conferred with its microscopic bubbles or cells of micrometer-size structure to the piece. These cells are characterized by having a diameter of 100 my, i.e. scratching the nanometer. As an agent of expansion, also known as "fluid", often use carbon dioxide, as well as in the case of the traditional of other polymers materials foaming, such as polyurethane (PUR), polypropylene (PP) and polyethylene (PE). "MuCell", a patented technology of the American company Trexel, is a standard procedure for the manufacture of special Microcellular foam. A large number of manufacturers that operate internationally offer modified molding machines injection ex profeso to incorporate this technology, which can be manufactured parts after the American owner of the patent license.

According to the own Trexel, another advantage of foams Microcellular to add to the weight saving material, is that machines of injection can be used with lower closing forces. The reason is that for the process of injection with fluid the required pressure level is lower. Added to this is that it can dispense with the phase of pressure maintenance and necessary compression in a normal injection process, so that the internal pressure of the mold is defined only by means of the injection process.

The experience of the German company Ticona GmbH confirms such advantages. This supplier of raw materials already put into service in August 2001 a machine of the Krauss-Maffei Munich company incorporating "mucell" technology, in order from internal testing and to offer an additional service to its customers. The tests in series by Ticona confirm the high profitability of the system. The main advantages derived from saving weight and reducing cycle times. Depending on the requirements of the final product, we could save between 10 and 15 per cent of the weight.

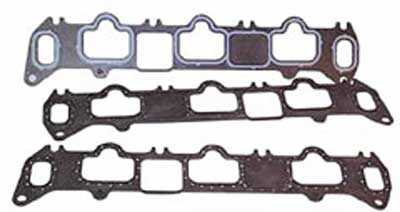

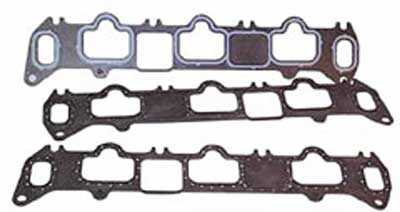

A conduit for automobile air component.

Rapid crystallization

The advantage that reports the "mucell" system on the cycle time, i.e., the interval of time between the stage of injection and the anti-corrosion, is that the molten mass loaded with gas crystallizes more quickly. This causes lower wall of the cavity temperature, which allows to shorten cooling time and extract before the piece of the mold. This quickly results in higher productivity and lower energy consumption. Serve as an example the iron with Ticona list made of the technical plastics "Celanex", a polyethylene terephthalate (PBT) butyl of own production: only to reduce the temperature of the wall of the cavity of 80 to 30 ° C, could reduce the cooling time a 40 per cent.

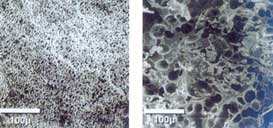

Izda., small cell and uniforms of the MuCell process. To the right., material foamed by conventional method.

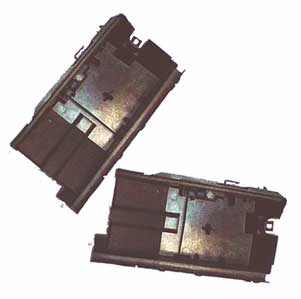

Piece of PP, with reduction in density of 60 per cent thanks to MuCell.

A conduit for automobile air component.

For Otto Schönherr, of Ticona, when weighing up the advantages and disadvantages of the procedure, they should be in the balance, as well as the economic aspect, other elements. Know perfectly the properties and the behavior of the piece manufactured with a new technology is one of the key factors for the success of this technology. Ticona engineers are working hard in the resolution of a wide range of issues in this regard.

And if the technical injected parts must comply with mechanical requirements exactly defined, then these conditions will mark, says Schönherr, if there are degrees of foaming corresponding to a reduction of 20 per cent maximum weight. The diameter of the cells that form the structure of the foam is located in the approximate range of 5 to 50 my. In this case it's polymer foams of cell in which cells have a nearly spherical shape.

According to the description of Schönherr, Ph.d. in polymer physics, Microcellular foams are characterized by having a compact exterior area, so the end result is a structure formed by this compact outer surface and a foam core sandwich.

This means that the Microcellular foams are in principle "composites": composite materials generated by the addition of components of reinforcement to the polymer matrix. The role of reinforcement of these materials, mostly oriented, lies in the case of "mucell" spherical gas cells. It has also confirmed the suspicion that Microcellular foams present significantly better bending properties of the classic foams. Something which is not surprising, because those properties of bending are largely dependent on the properties of the fibers of the external structure.

Absence of rechupes

At the beginning of April this year the center of the plastic of the South of Germany (Süddeutsches Kunststoffzentrum) held a seminar in Würzburg, on the banks of the main, on the physical foaming in the transformation of plastics. Among the speakers at the event, held on the premises of the Institute of Würzburg, were chemical processes from different companies and departments of research from universities, as well as Martin Witulski, Manager of the German company Schröder Kunststofftechnik GmbH.

The use of this type of foam allows to save material and, therefore, weight and costs

Schröder is a transforming company of plastics that ranks among the pioneers in the field of the type Microcellular foam. Since the middle of last year, the company has an injection machine which incorporates the "mucell" technology, enabling him to Witulski report at the seminar of the SKZ in the newly acquired experience with the implementation of this relatively new technology. In his speech he referred to the clear advantages of the system and the notable benefits it brought to his company's clients, and referred to the close collaboration with Ticona.

Witulski concluded, as a positive feature, that there is a real potential for savings through the reduction of cycle times. He also confirmed that, indeed, is achieved a reduction of the weight of the injected parts. Also are they could reduce or even eliminate fully unwanted defects of finished, deformations or rechupes products and dispense with the expensive work of retouching. However, according to the experience of the Schröder House, the application of the method "mucell" does not automatically guarantee a higher degree of process reliability. Therefore Witulski confirmed that since it had found Ticona: that it is necessary to go acquired a considerable experience to master the procedure and to take advantage of the benefits that is able to offer.

Related Companies or Entities