The manufacturer of aerospace components Meyer Tool "reduces" the costs of tools of control through the Equator caliber

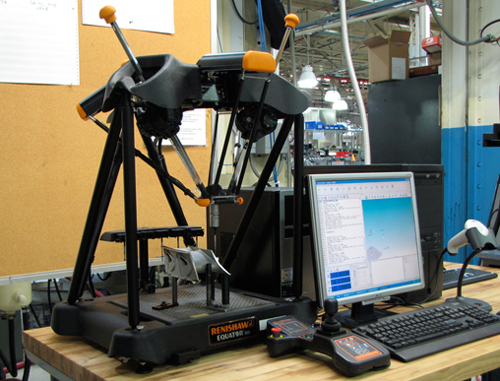

Thanks to the new programmable caliber Equator of Renishaw, meyer tool, Cincinnati OH, aerospace components manufacturer has begun to reduce the costs caused by the large number of control sizes. Meyer Tool designs, manufactures and maintains dozens of expensive tools every year for measurements in process.

Through Equator Renishaw calibre have been removed at least four costly checking for a new cell production fixtures. "This is only the beginning of the impact provided by the company in its inventory of checking fixtures, where the cost of design, manufacture and maintenance can reach 20,000 U.S. dollars per unit," said Beau Easton, director of the company's quality, "in practice, the design changes may involve additional $3,000 to 10,000 in costs of reconfiguration and calibration of fixtures".

Cost reduction in checking fixtures

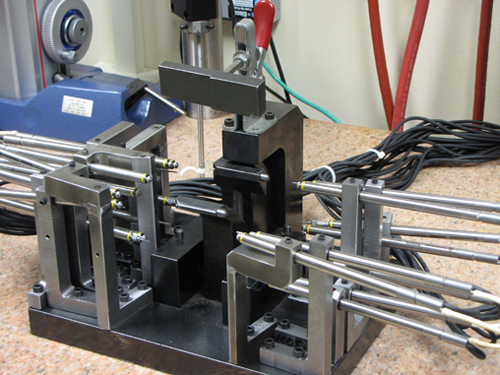

For dimensional measurements during the process, the company trusts mainly useful contact point, using pneumatic digital probes. Fixtures, located in autonomous production cells, provide very quick results, but are expensive. The design and manufacture can cost up to us $6,000, over $500 of each probe, studies of verification and the maintenance, explains Easton. "To produce a complete set of injectors, we would need between six and ten tools, each with six to twenty probes, and if you change an element or the tolerance of the piece, should include the time of modification and verification of the piece."

When we present the caliber comparator Renishaw Equator and offered them the possibility of having a unit test before its commercial release, Easton and Director of SPC, Bridget Nolan, claim that they recognized the potential immediately. "We get involved in the presentation of the Renishaw system and supply parts." Renishaw programmed them and their results agreed with the results of our machine of measurement for coordinates (MMC) ", says Nolan, whose team prepares, maintains and program tools and instruments of the company."

Comparison, Master piece and repeatability

Although its appearance is unusual, the Equator system uses the method of comparison of a master piece, this method is known by any user of checking fixtures. Used one-piece master, in which the measures of the elements are known to control the system is set to "zero", and compares this piece in all subsequent measurements. The most important of the Equator system is its high repeatability and radically different, based on a structure parallel kinematics. This mechanism is lightweight, which allows a rapid, although very resistant displacement and repeatable. The system uses probes of exploration and contact Renishaw, probes and probes automatic changers, and the programming MODUS Equator software. With regard to costs, an Equator replaces between three and five useful in a manufacturing cell Meyer Tool, in addition, the Equator can be used for various parts, alternating between them in seconds, and can be reprogrammed to many other pieces throughout their lifecycle.

Installed in a production cell

The Equator system is currently integrated in a production cell located in the workshop of Meyer Tool. As a test of adaptability, integrates with the system SPC Orion by Meyer, retaining its familiar look and feel for users and shortening the learning curve. Orion communicates with software MODUS Equator, and displays the results in the form of dimensional data, graphic SPC, etc., which allow you to modify the program of machining to the operator. "Remember that the user sees the results and can compare the current piece with recent measurements, therefore, is not only an instruction in accordance of approval/failure", Nolan says. The pieces must support tolerance of ±0, 001 to ±0, 003 inches. The duration of inspection varies according to the piece, but it usually takes between two and six minutes, perfectly within the TAKT time of the cell, so the system easily maintained the pace of machining operations.

"Currently, inspect five types of piece for two programs of different engines, therefore we have several plates for the adjustment and calibration of Equator", says Nolan. "We tried to combine as many different operations as possible to limit the calibrated, we are currently working on a plate that combines three." We are working on real positions of GD & T, slots, diameters, profiles, eccentricity, and similar through inspection by contact, we are therefore implementing the inspection by contact with the SP25M probe. "We have an automatic changer of probes and use at least four different probes, - often probes into star - making it very practical to avoid having to repeat the calibration after each change", signing Nolan.

Measurement standards of MMC

Measurements of Equator in Meyer Tool saved correlation with an MMC, using a piece of master in MMC. "The master piece sets the values that Equator expects to find within the measurement environment, while the software automatically applies the values of compensation on the nominal retrieved in the MMC." "The check is performed within 10 percent of tolerance permitted with respect to the nominal", Nolan explains.

It is not necessary to remaster after each piece, however, Meyer has decided remaster every 3 hours to compensate for changes in temperature of the plant. "The Equator system memorizes the masterpieces, therefore we can switch the pieces as many times as necessary in a window of 3 hours without need to remaster," Nolan says.

Meyer Tool committed to quality

Meyer Tool is one of the leading manufacturers in the U.S. of components for combustion turbines for manufacturers (OEM) of aerospace systems, with more than 1,000 employees in ten plants. The headquarters in Cincinnati (one of the ten largest companies of the city) specializes in new parts, while in other facilities of Meyer work in repair and start-up to point for OEMs. The main materials of work pieces are alloys of nickel and cromo-cobalto.

With more than 500 fast drilling EDM, Meyer Tool is the leading manufacturer based in EDM of North America. These machines are supplemented by grinding, more than 300 EDM of conventional attack EDM 45 stations, most of 3 and 5 axis CNC machining. The EDM of the company bore holes more than 1.75 million a day, but, knowing that a hole between several hundred blocked can cause failures in the blades of high pressure military, Meyer Tool is obsessed with quality. The company employs between 10-15 engineers from quality, eight supervisors and a SPC team of five members. "We started to implement the principles of Lean production more than 10 years ago, after the AS9100 certification," Easton said. "But investment has been profitable". "For the first time, our rate of return in January 2011 is 98.9 percent, i.e., the first time that machining is complete without pieces rejected or not compliant".

This has been achieved by applying the information in real time at a much higher level, adds. The backbone of the information of measurement of the company, the SPC and the quality system is the Orion software and workstations, marketed through its subsidiary Sigma Technology Services. The pieces are inspected at 100 per cent through various methods, including laser exploration and inspection by contact in MMC, visibility of 5-axis, radiometric measurement and exploration of flow path, among others, all of this managed network in the Orion systemserving as a common interface for the operator in the systems of measurement. Measurement programmes, the results and the SPC data are managed by the Orion system. When an operator completes an operation in a piece, it scans the serial number in the system, measured the piece, and presents the result immediately to the operator, who can compare with the latest 35 measures similar pieces. "Is possible to scan the serial number of a piece in any terminal of the plant and see the results of the measurement," says Easton. "The information is kept with the piece." Before releasing it, all inspection data are checked to verify that all the points, has been rejecting the piece if it does not exceed any of the controls. "Our rate of rejected pieces is virtually non-existent, and the client knows."

The "soft" solution to the costs of gauges

With more than 100 useful at a cost between 10,000 and 20,000 US dollars each, Meyer Tool recognizes the advantages of cost potential of a system of flexible arms controlled by software. "We continue to increase our knowledge and the possibilities of the Equator system, but we have great confidence in that it will eventually reduce a large part of the cost in useful," adds Easton.