Wittman introduces its new range of products in Austria

June 5, 2010

A fast and efficient system

The new robot series W827 Primus is based on the successful linear robot W727 side entrance, which is used in many systems of elimination of embases and applications IML (In Mold-Labeling). The change in the new R8 control in all the horizontal linear robot system gives access to several functions of the standard robots Wittman W8 series. Included in a long list of new features, highlights the function SmartRemoval, for the reduction of the time of opening of moulds; TruePath system, for the optimization of the control shaft engines; and the integration of robots W827 controls B6 Battenlfed mold injection machines.

Another new feature of the R8 is showing the duration of each of the functions with a precision of milliseconds. Measure the time of each step in the process help to optimize the cells of working to maximum efficiency, especially for the emptying and filling at high speed of mold injection machines. All this leads to avoid any kind of delay. Show working time also offers the user an analytical tool of great practical value, to filter out the unnecessary time and delays which tend to produce those inefficient processes. In addition, it also provides an optimization of functions and sequences of the robot.

A perfect combination of advantages

"The Drymax Aton combines the advantages of a center of constant gotaje with maximum efficiency." This is possible, as they claim Wittman sources, through the construction of a completely new drying Conference. The new wheel of drying of Wittman is formed by a series of rooms, which contain a molecular sieve flexible accumulation.

This construction explains the high energy efficiency, as well as the circulation of air in the molecular sieve can increase energy and heat transfer. On the other hand, the current wheels in the form of honeycomb are formed by sheets, to which is attached the desiccant, but from a design point of view, only has been made very minor circulation of air. This translates into increased consumption of energy in relation to its capacity of dry air. New dryer Drymax ATO presents for the first time a second mode of patented operation, the so-called EcoMode. Depending on the degree of burden of water from the dryer, this works well in the mode of continuous wheel or in the Quasi-2-Bed, the so-called EcoMode mode.

Wheel mode, molecular sieve-filled sections of the wheel are continually on the move, while the separation in the process of drying, natural regeneration and the cooling is still. The regeneration of energy in the opposite direction to the flow of air was removed from the drying 2-bed. This means that he is achieved by a high energy efficiency, in connection with the use of all the energy of cooling for the process of drying of the wheel of drying Wittman. The consumption of energy in the mode of wheel is not even comparable to a bed 2-desiccant dryer. In this mode of operation, a point of continuous drip can be maintained, since that also satisfies the highest demands of dehumidification system, for example working with the material or maximum performance with very wet granules.

However, if the change in operating parameters and a lower level of dehumidification system are necessary, Drymax ATO dryer switches automatically to the EcoMode mode. In this way, the dryer is operating in a quasi-2-bed mode, in which various segments of the wheel are combined in a section of physics and operating simultaneously. The advantage comes from the fact that the dryer now works with a load of under water and the phase of regeneration heating turns off half the time.

Active protection against blows

One solution is the system of the robot controller R8, on the one hand, with the areas of security FlexSafe. These can be as arbitrary and easily through the TeachBox R8. The critical areas - e.g., tie bars - or the safety of the guards of the moulding machine can protect intentionally operator errors. The only robot can move within the areas of security, and movements outside these areas will be completely disabled. Up to 255 areas you can set form and displayed in 3D view. All the axles tyres, as the movement of the expensive robot doll, will be monitored in controls real-time programmable security areas.

Follow-up on time complete, regardless of the current operation (automatic or manual) of the robot mode provides safe operation and complete control of all motions. Also a transparent overview of the sections of security on the screen of control of the R8. The areas of security FlexSafe can be defined on a voluntary basis, with the effect that not all the robots are protected as such.

A robot for bottling beverages

The customer can select from a list of menus well balanced between non-alcoholic and alcoholic beverages. Selection occurs in the R8 TeachBox touch screen of the robot, not, as usual, from a list of menus in the traditional sense. The so-called Auto-Switches, i.e. shortcuts easily programmable for optional features in the standard robot application, indicate the various drinks. If you press button Auto-Switch sends the robot to find the corresponding bottle. They move through the workspace of the robot in a conveyor belt in constant motion.

A camera connected to the processing of the Cognex In-Sight 5000 image system is mounted on the robot arm, and recognizes that it passes bottles in the March. Once the desired drink has gone and has been recognized by the system, the robot begins its movement. The bottle grabs conveyor in movement and is transported to the station's independent opening. The cover will be prey to a universal and twisted bottle opener open. The open bottle is presented below to the customer.

High precision water regulators

The injection moulding process is demanding for the cooling and tempering, respectively, of the moulds. The connection of the circuit carrier of heat the mold can be done using any of the tracks in series or in parallel. Normally a unit of temperature measurement of the flow control is applied, when a circuit is used in series. But this is impossible for the method of parallel circuits, because this needs a unit for the temple and a regulator of standard flow (with at least an optical indication of flow). The optimal solution for this problem is the flow control of water offered Wittman (WFC).

This model is a combination of flow regulator and flow measurement. All variations of the system are detected in time, because the data acquisition process is carried out permanently. The reproducibility of the differences is therefore guaranteed when using the unit Water Flow Control (WFC). Blocked channels or pipes broken (for example after having changed the mold) are a thing of the past, because such problems are immediately detected. The flow non-contact measurement has been integrated into the basic element of the series 230 Wittman WFC and is connected to an electronic indication and operating unit. The value of adjustment of flow can easily be performed by the operator, using control valves. Values can be provided easily with tolerances through the unit of entry, and it can be controlled by connecting to the machine of molding by injection.

The WFC is high compactness, thus offering the possibility of mounting the system on the smaller machines of molding mounting plate by injection. Beyond that, only use non-corrosive materials. Wide 100 Wittman World Forestry Congress measurement lies between 2 and 40 l/min per circuit, the maximum operating temperature is 100 ° C, and the maximum pressure is 10 bar. The accuracy relatively high measurement of 1.5% FS (Full Scale) represents a deviation of ± 0,5 l/min from the main application temperature range.

Granulators of high performance at low price

The number of mills Wittman MC Primus conventional have been developed specifically for recycling of soft plastics to media and it will serve as a bridge between the line of granulators ML beside-the-press to the line of Central granulators MC. The new MC Primus models have an open design of the rotor to provide optimal airflow through the Chamber of court to avoid thermal degradation or melting of the material. The rotor opened 3 x 2 blades bent in motion (also known as the 'fish bone' rotor) combined with two inclined fixed blades offer a cut of double scissors that improves the quality of the crushed materials and dust reduced to a minimum. The rotating and fixed blades several times depending on the amount of wear and tear can sharpen.

The units are equipped with a modular design that allows the customization for a specific application:

• Standard collection tray can be used with a fan, but it is also equipped with a quick closure for use with a hopper loader.

• Additional electrical options can be easily added with the Cabinet mounted on the frame.

• Several different designs hopper are available for different types of waste food.

• Acoustic insulation for additional silent operation.

• Additional flyers to increase the power of rotation for the recycling of hard parts, such as thick of blow molding pieces.

• The hopper of evacuation and tray of crushed, that they are in contact with the crushed materials, they are made of high-grade steel. The movement of the back inclination hopper with assistance through gas cylinders.

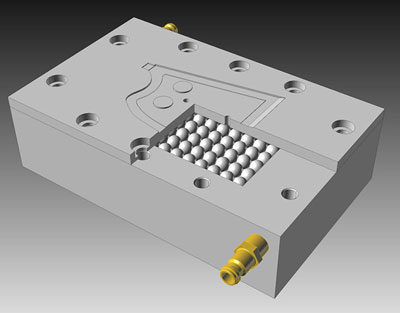

Innovative temperature regulators

Compared to conventional heating and cooling of channel tools, BF-Mold technology can be used throughout the area under the cavity for the heating and cooling. In addition to the thickness of the wall between the part and the Chamber of cooling can be minimized through the addition and support of the balls. This process completely new bottle is used in combination with the Wittman Tempro plus C160 / 2 Vario, with dual-zone temperature control, which were developed specifically for this processing technology. For a better consistency dimensional of the parties, as well as to prevent the traces of the sink and the lines of welding, the first zone of the Tempro puls Vario generates a high temperature in the wall of the cavity. This keeps the cavity above the glass transition temperature of the plastic injection process optimized time.