Increase productivity with Delcam PowerMILL

May 17, 2010

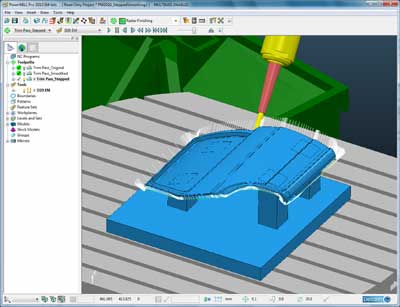

PowerMILL 2010 continues to improve the productivity of the user promoting the processing technologies available in the current hardware multitasking and background. The combination of these two developments expected to reduce the time of calculation up to 25%, although this depends on the complexity and size of each piece.

PowerMILL 2010 includes more than 50 major improvements that optimize the speed and ease of programming, more efficient paths and more quality in the surfaces of the parts. The most obvious change for users is the update of the forms of creation of trajectories with a new and improved design. In addition, it has a new toolbar to facilitate and streamline the creation and editing of plans of work.

It has also added a number of strategies for roughing and finishing corner, obtaining finishes more efficient and smooth, especially when a tool of greater dimension is used for initial roughing leaving a considerable amount of material in the corners.

Roughing of remains has been improved to better control the starting points of each segment of the path. This entails a considerable saving of time of machining, minimizing the movement of the tool in the air.

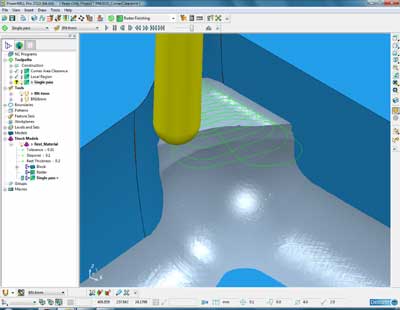

Roughing offset, very popular in high speed machining has been improved so that thin walls that can spoil the tool in the last final should not be. PowerMILL automatically identifies these potential problems, and adjust the last final to give a thick the material smoother and therefore safer.

In addition, improvements have been made to create more feathered paths for semi-acabados and finishes. These trajectories minimize tensions in the cutting tool and machine tool, improving the quality of the surface finishes.

New options have been developed to avoid collisions and give more control over the direction chosen by PowerMILL to solve the problem. This functionality is particularly practical in areas where there may be a sudden or abrupt change of direction.

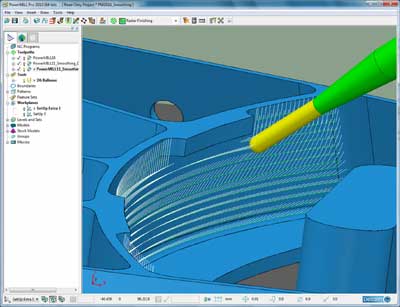

Trajectories in constant Z have been improved to include the detection of flat areas and the automatic inclusion of additional Z levels to be machined accurately.

Also added a filter to remove small segments attached to the trajectory, as these can damage the cutting tool. The combined strategy of machining "flat and pending" uses this novelty in sections with steep slopes and offers new options that are specific to flat areas.

Finally, a new option that specifies the locked profile safer for any group of paths. This helps to identify the more rigid tool that can be used throughout the programme without the risk of collision.