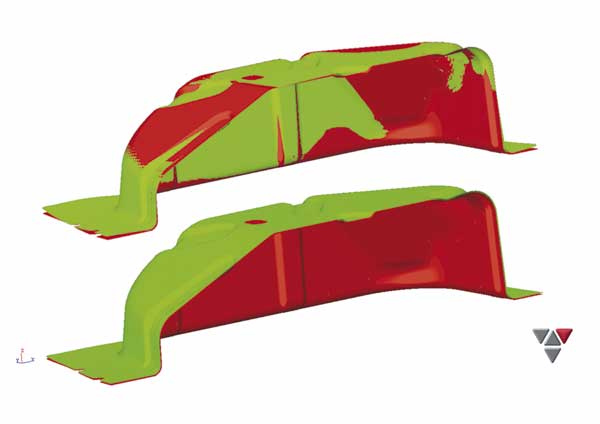

AutoForm presented an application for compensation of workpiece and tool geometries in the BIEMH 2010

Among its features is that springback compensation can carry out in a few minutes, even for side panels, thanks to a new highly specialized algorithm. It is a solution easy and flexible to implement that he ensures that springback results are automatically used to compensate for the tools and that validation is carried out through the simulation. That compensation is carried out at the beginning of the process makes that the layouts of the processes are more reliable and easier planning of Assembly operations.

The main benefits of AutoForm-Compensator are:

- Reduction of the time and costs in engineering and tryout

- Improvement of the reliability of planning in the development of the matrix, press and Assembly

- It takes into account the costs of the springback for more precise tooling and stamping offers

- Improving the quality of the piece and the tools