Renishaw, at Biemh 2008

February 21, 2008

Measurement by interferometry XL-80 laser system

For applications in process control of machine tools, the Renishaw TRS2 tool recognition system, it takes, usually less than a second to detect broken tools; for users seeking a reduction in the time of inspection in the measurements of geometry of complex 3D parts of any size in machining, the new probe for Renishaw RMP600 contact centres, compact, high-precision and Renishaw radio signal transmissionIt is the most appropriate solution.

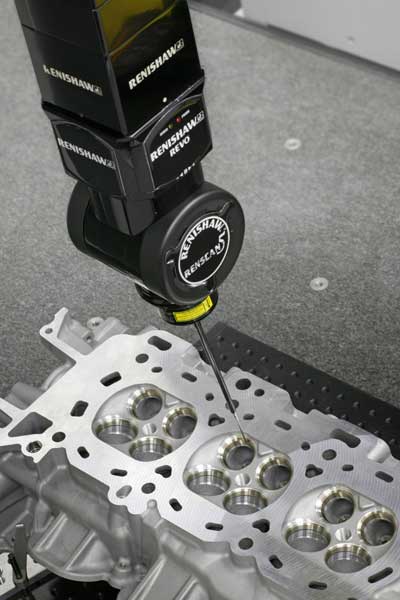

Revo inspection system

The revolutionary system of inspection measurement of five axes Renishaw Revo head has the built-in Renishaw Renscan5 technology

The key to the success of the head of five axes Revo lies in its ability to overcome the limitations of the methods of inspection of three axes, where any attempt to quickly move the great mass of a MMC would produce errors of inertia caused by the accelerations and decelerations. Therefore, the only possible way to maintain an acceptable accuracy in the inspection of three axes has been at the expense of sacrificing the speed of measurement. However, Revo employs synchronized motion of the head and the machine during the inspection to quickly detect changes in the geometry of the piece, without generating dynamic errors. The MMC can move at a constant speed during normal measurements without affecting accuracy.

Contact RMP600 probe

Renishaw RMP600 system is a compact touch probe of high precision, with transmission by radio signals, which provides all the advantages of the automatic preparation of work

Detection of Rengage effort Renishaw's patented technology, the RMP600 probe can reach a degree of precision far greater than that obtained with a standard mechanical probe, so it is best suited for a wide range of applications where a high precision measurement is essential. Rengage technology combines sensors of detection patented an advanced electronic system that allows to obtain a performance of inspection 3D below the micra contoured surfaces, even with a long probe.

Gauges of effort also allow that the probe RMP600 can shoot with much more consistent and low contact forces, therefore, reduces the flexion of the transducer and the variation in displacement to obtain a precision far greater. Despite this precision, no is compromised his great strength, that resists the blows at the same level as other probes for machine tools, leaders of industry, of Renishaw.