Wittmann presents their new gravity dispensers and their mills and crushers

Dispensers

The Gravimax dispensers offer a technology RTLS 'Real Time Live Scale' (weight in real time) that allows to weigh the different components thus the amount of accurate and constant in each batch.

This technology used by Wittmann is completely different to the usual systems in the market, which work with fixed times during the dosing process, and only during the next cycle are a correction of the times for each of the components.

In order to meet the most demanding requirements of RTLS technology, the Gravimax dispensers are equipped with a fast electronics and high-quality, which makes possible weighing cells more accurate measurement. Thanks to its control through touch screen offers an additional advantage that it allows an easy and simple access to its various functions.

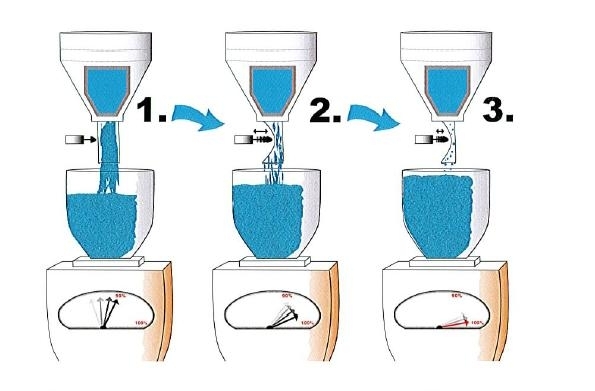

His method of measurement in 3 easy steps allows a more precise and exact feeding batch to batch. This is possible using impulses of food progressively smaller until reaching the desired weight. A single type of standard valve of high precision for dosage of material into pellets, crushed or dust is only used.

The dispensers Gravimax range from the smallest model, GMX 14 with an output of 130 kg/h and 4 components, to GMX 27 with an output of 5000 kg/h and 8 components. This wide range of equipment can cover all the requirements of the dosing gravimetrica commonly found in the market.

The software has an open communication protocol that can be used by any user HMI and any data acquisition program. (Ethernet or wireless connections required).

Users can retrieve and store all lots and information of alarms from multiple mixers with a simple Ethernet connection.

Wittmann, with its 9 manufacturing plants, provides for the processing industries of plastics from around the world a complete and innovative technology of automation and auxiliary equipment ranging from autonomous work cells to totally centralized control systems. Products include robots, regulators of flow of water, temperature controllers, mills, dehumidifiers, gravimetricos, inhalers color mixers, individual feeders, centralized power and injection presses and IML systems with integrated molds.

Mills and crushers

The family of low-speed without grid-breakers has been expanded with the addition of the Minor 2 model. This new model is equipped with 2 groundbreaking blades and 3 sections of cutting of roller of trapezoidal section in the rotor. The Chamber of Court has dimensions of 240 mm x 249 mm (9.4 "x 9.8") and represents the best option for flows of greater dimensions or small parts.

The crushers without grid line has been expanded with the model Sumo JD8 - 3, with a Chamber of the Court of 588 mm x 530 mm (23.1 "x 20.8"). The crusher Sumo JD8-3 is equipped with a third axis on top of the Chamber of the Court to ensure the proper introduction of pieces that are going to be impacted by the blades and cutters in the rotor.

Both developments in the Sumo program offer the same advantages as other teams without grid of Wittmann: operation with low noise and size of uniform particle with minimum presence of dust, wear and reduced to low rotor rpm 27 and simple handling and cleaning systems.

Series MC of Central Mills included the incorporation of the new MC 46 60 team with a Chamber of the Court of 460 mm x 600 mm (18.1 "x 23.6"). This unit will be on display with feeding conveyor and operation of rotor for optimized recycling of PET bottles and other components of blow molding. The hopper of the mill can be adjusted to a wide variety of methods of food (e.g. manual, robot or conveyor).