The importance of filtering in a machining company

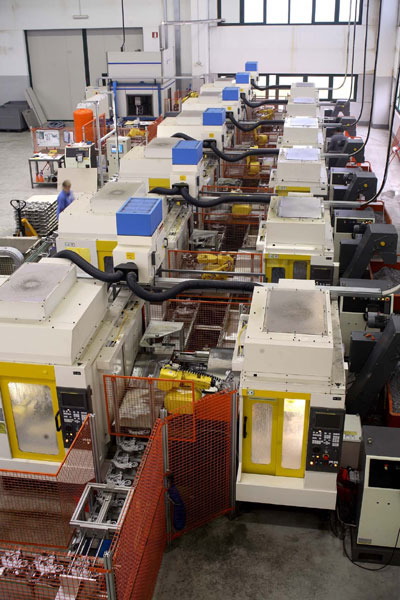

TMB Tecnomeccanica Betto, SpA manufactures light metal components for industrial sectors such as the of the electromechanical, pneumatic, cars and safety equipment. Performs mechanical applications of grinding, milling, turning and threading on pieces printed (by merger or die casting), creating finished pieces ready for assembly lines (just - intime). In some cases, they also carry out the preensamblaje.

Numerous orders have forced a third factory, equipped with new machinery and systems automation, robots for the loading and unloading of machines and automatic washing systems.

This new facility is totally dedicated to the manufacture of components of size medium for automobiles; as for example: carter for pumps, pumps for oil, EPAS steering boxes, seat zipper for hydraulic power steering, accommodation of e-cards and components for braking systems. The piece finished through a blowing machine shavings are removed and cleaned. It testifies the garrisons of the piece ("tightness test") and are subject to evidence of porosity, cracks and dimensional controls.

Eliminate pollution

During a process of continuous production, with three shifts of work, often at high speed, the machine tool is continuously in contact with metal, removing shavings and creating heat. The coolant vaporizes spraying with other elements. Without intervention, these oily mist are disseminated in the environment, contaminating everything, including the lungs for those working in the factory.

TMB Tecnomeccanica Betto is very sensitive to this problem and for many years all the machines have been equipped with suction and filtration systems. However, in 2003, during the last enlargement with the construction of the plant number 3, flaws of the old system of filtration have discouraged their use. Stefano Betto, technical director of the company, explains that: "the peacekeeping has always been very difficult." They are built so that it is very easy to damage them and therefore need to be frequently arranged. Moreover, its ability to filter is not very efficient. Therefore, we have opted for another solution, that found us most effective from the first encounter with the Builder. "This new system has been compared with others prior to be installed". They were compared according to criteria of structural strength, degree of purification, cleaning of the work environment and maintenance. We then rely on AR Filtrazioni, a company located in Bergamo since 1988 ".

A year after the election, Stefano Betto clarifies that "with the purifiers air AR Filtrazioni our warehouse has been purified." "Comparative tests with other brands have shown that only the AR Filtrazioni air purifiers eliminate that tank of oil uneaten everywhere and once on the ground creates security problems for all workers".

Today, all the machines on the TMB 3 installation have an AR Filtrazioni team: "A year after the installation and after having made an ordinary maintenance, without extraordinary interventions, there aren't any trace of oil in the grid on the air purifiers"where the purified air back to be introduced in the work environment.

The results confirm that we made the right investment. The simplicity and speed of maintenance are exemplary, thanks also to the visual detector which shows the level of saturation of the filters. "The truth is that filters are somewhat more expensive than the competition, but its use is justified by increased performance and efficiency and the fact that his change is possible in just few minutes."

For high productivity machines air purifiers

The Mission of AR Filtrazioni can be defined in one sentence: "solution of the problem and total satisfaction of the customer, the machine tool in organic rasformando and not ontaminante." Angelo Riceputi, Director-General of AR Filtrazioni, says: "our air purifiers have been created for machines of high productivity, with three-shift working, trying to cast iron and aluminum with pumps high pressure electric." Our goal was to ensure a clean environment, with clean air, a machine solid, efficient, reliable, durable and with a simple and fast, keeping that decreases the duration of unemployment of the machines. In 2000 we created ARNO and today is our main model. Its strong points starting with their structural strength, which includes a perfectly balanced rotor. But the heart of the machine is the sequence of filters, a combination of filtering stages that maximizes its period of life and efficiency, which allows to introduce a completely clean air in the work environment. During the third and final stage of debugging, a HEPA filter is used until the category H13 (according to the European classification in 1822).

This is an absolute filter, after which the residual concentration of contaminants analysed at the exit of the team is less than 0.1 mg/m², a value much lower levels internationally recommended.

High reliability is critical to an auxiliary equipment of machine tools, whose strikes may involve very large economic losses. The success of the ARNO series has exceeded our expectations; "a product does not always so successful."

Riceputi continues: "we are suppliers of large companies, also provide equipment to many and important builders of machine tools, equipping its machines directly with our air purifiers." In addition to the products, we also offer a turnkey installation service and personalized maintenance. The frequency of interventions and the same maintenance, are planned and certified by a program specifically created. Recently the value of this program has been recognized by an important body which has awarded ISO 14001 certification to an our client, who works in the automotive sector. In 2002 we improve the solutions aimed at abatement of fumes produced by machines laser (new manufacturing technology).

His last success is a new series of purifiers air developing with magnesium, a light and strong material that is used increasingly in the automotive sector. However, it is difficult to handle, since material that can burn and can exploit. This new series of air purifiers has been on the market for two years and is already a success by numbers and benefits.

AR Filtrazioni does not air but that purifies

The recent difficulties in finding sources of energy, the great demand for oil from Asian countries, the air in our cities reaching at winter levels of micro-powder much higher that the limits of safety: "confirm the need for our work" says a. Riceputi.

In the industry, the choice of a team of efficient individual cleaning is critical for any sensitive company to the containment of fixed costs, to respect the standards of health and safety and the environment. To give an example, we have to remember that by N m cubes of air coming out of the factory, N m Air hubs have to re-enter. There are 1.000/2.000 m _/h of air in each machine tool to clean up. It is therefore obvious, that emit air pollution directly to the outside of the factory is a contradiction in terms. That does not only mean that the problem (air pollution) is simply moved to the outside, but also that the hot air is diffused in winter and cold air in summer. This continuous Exchange creates depression in the workplace and imply that the heating system is always running.

This is one of the causes responsible for environmental pollution and one of the higher costs of a company. The AR Filtrazioni team does not air but that purifies.

In this sense, the company has been the results of an analysis carried out by a certified laboratory, about the leak of the oily mist through the use of the AR Filtrazioni equipment installed on machining centers MCM. Analyzed machines work twenty-four hours a day, 7 days a week. The sample was collected directly from the output of the debuggers after continuous use of 7 months. The evaluation, based on the system of reference UNICHIM, has been demonstrated that the pollutant concentration in mg/m² is less than 0.1. By what refers to energy saving, Angelo Riceputi stresses that "individual debuggers to direct focus to the source are as"clothing to measure", created to meet the needs of each machine tool according to their size, type of fairing", capacity of air, fluid worked used, material cutting and time of use of the machine tool. "Otherwise, a team centralized always works to the best of their ability".

For a company, save does not mean only that the energy can be subjectivity, but also that the distribution of industrial plant may be modified, as the individual team can follow in the machine tool when this is relocated. In addition, each machine is equipped with a system of drainage for the recovery of the liquid recondensado, that is returned to the machine tool for reuse.

Very fast maintenance

AR Filtrazioni air purification systems are designed for machines that work in high series with taladrina, oil or dry.

It's a patented system of cleaning air allowing quick and easy maintenance every 4,000 or 5,000 hours with a stop of machine in 5 minutes.

The ARNO system has 5 stages of filtration and the last stage of filtering has a HEPA filter. This is an absolute filter after which the residual concentration of contaminants analysed at the exit of the team is less than 0.1 mg/m3.

Performance of 99.97%.

Application: centres of machining, lathes, grinders, transfer machines, sharpening of tools, EDM machines, milling machines, laser machines, washing machines, gear, etc.