The system of peletización for PET allows important savings when producing and crystallise granules

10 March 2014

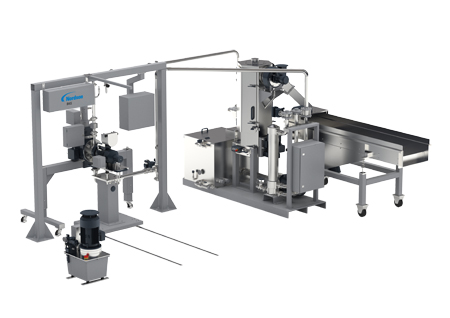

An integrated system that uses the thermal sensors power of the polymer melted in the peletización of PET for the crystallisation, deletes the problems caused by the agglomeration of amorphous material and reduces substantially the costs of power for formulation or recycled of compounds, as

For being an integrated network that incorporates the peletización, the dried and the crystallisation under the water, is designed for a precise control of temperatures of materials in all the process, what avoids the problems of production and quality caused by an insufficient crystallisation and excessive levels of amorphous material. The efficiency in power of the system CrystallCut can save more than 3.000.000 € in costs of annual power for a plant of resin PET typical and almost 200.000 € for a line of extrusion that recycle flakes of bottles of PET, according to examples mentioned by Nordson BKG based in real commercial installations (see in the graphic an example related with the polymerisation).

In the system CrystallCut, the material granulated of PET hot produced by the plate of cutting of the peletizador under the water transports quickly to the dryer of granules in hot water (until 95 °C) through tubes of enclosed transport, where occurs the cooling and the solidification of the granules. This half of transport and the short distance between the plate of the cabezal and the dryer are key to conserve the heat of the processing of material melted. The granules are to a temperature of 150 to 160 °C when they go out of the dryer in a vibratory conveyor. This keeps to the granules in constant movement, generates a uniform distribution of thermal sensors power and avoids that the granules adhere between himself. When finishing the process, the granules have a temperature of roughly 180 °C, attain a cristalinidad of until 40 % and can transfer directly to the policondensación of solid state (SSP).

In addition to saving costs of power and avoid the agglomeration of PET amorphous, the system CrystallCut provides a product almost totally free of dust and increases the density of the material to granel in 8% regarding a conventional process. Supposing a cost of power average of 12 cents/kWh, Nordson BKG calculates that the system CrystallCut offers savings of power of until 125 kWh or 15 € by tonne of PET in a plant of polymerisation of PET modern. Since a plant can attain a capacity of production of 600 tonnes by day, these savings equivalen to 9000 € daily and 3.200.000 € by year. This represents a saving of annual power of more than 26 gigavatios-hour, or 26.000 megavatios-hour. Another example that mentioned Nordson BKG is a line of extrusion that recycles flakes of bottles of PET to a speed of 1500 kg/h. The savings that can attain with the system CrystallCut surpass the 180 kWh, or more than 1,4 cents/kg. In a continuous operation (24 hours, 365 days), this equivale to 190.000 € by year.