“Can not it do more ecological”

Motan-Colortronic Develops a technology of crystallisation of poliestireno expanded ecological

Innovative products like an EPS resistant to the fire and an EPS able to absorb the radiation, find between the innovations of the Dutch Group Synbra. With it consigns it “Groener kunnen we het niet maken” (“can not it do more ecological”), the company finds now promoting his more recent innovation: BioFoam, a foam patented of plastic expanded for different applications, like packaging and isolation. Two types of acid láctico turn into láctidos to obtain sour poliláctico amorphous from them. From here the basic material for the production of malleable materials.

Motan-Colortronic, Synbra and Ora Machines join in the development of BioFoam.

Roughly, 99% of the prime matter of this EPS ecological comes from of plants. However, the process also can arrive to realizar a complete replacement of the raw materials based in the oil, and already has found a complete range of utilities for this ecological foam.

Crystallisation with special requirements

“The chemical knowledges were available to some extent, after all, also produce the poliestireno we same for our products established. Besides, we hire to personnel of an institute of the Wagingen University, with which are headlines of conjoint patents nowadays", indicates Jan Noordegraaf, General Director of Synbra Technology, “was clearly possible to test the processes of a comprehensible form in the laboratory. Nevertheless, still it was a pending question know if it would work on a large scale and how would have to design the individual components of the installation. An element determinant for the success of the process resulted to be the crystallisation.”

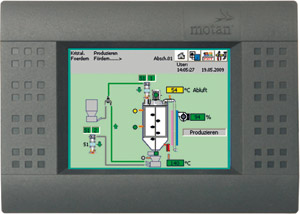

A special system of control of temperature guarantees the prevention of empty and adhesions.

Like motan-colortronic already had supplied several installations to Synbra through his partner of regional sales Ora Machines, the proofs in the technical department of motan-colortronic showed that the already existent plant of crystallisation could use for the new product. Basing in a standard installation, the technicians of applications of motan-colortronic adapted the process for industrial use.

The challenge consisted, among others, in a window of process very narrow. For this, developed a special system of control of the temperature to guarantee the prevention of empty and of adhesions and attain a complete crystallisation. The material keeps in intense movement in the hopper and processes in a very narrow window.

Advancing to a real process

Once that the crystallisation and the process of dried had showed his functional capacity in the technical department, Synbra began with the real operation in his own plant. To achieve it with rapidity and risks very calculated, Ora Machines loaned to Synbra a cristalizador of laboratory and provided knowledges on the process through his own personnel. “We have selected consciously to motan-colortronic and to Ora because both companies work with his own technical departments and were lists to assume the responsibility by the development. This is very important for us, especially with products entirely new as it was the case with BioFoam”, affirms Jan Noordegraf like justification of the form in which it handled the project.

The mezclador is extremely robust and resistant to the torsion.

The operative experience collected in the cristalizador optimised type Luxor HDC and adjacent equipment that developed especially for this project. The result is the hydrolytic degradation of the material and the energetic consumption by means of the use of an exchanger of integrated heat. The construction of a mezclador standard extremely robust and resistant to the torsion was of particular importance in this case, because of the properties of the material. The control of the temperature optimised on line with the narrow window of process and the sensitive control of the quantity of air with accionamientos regulated by frequency. The material produced is used to to contain of 100 to 150 ppm of residual humidity.

The line of crystallisation and dried of PLA with a maximum production of 800 kilograms by hour can scalar, and therefore, can attain greater taxles of production to measure that increases the demand.