Fagor Automation in the EMO shows its new CNC 8060

FagorAutomaticparticipation at the EMO exhibition in Hannover 2013 is starring the new CNC 8060, designed in the user's machine to give you the best solution for machining centres and lathes, production and maximise them.

The new CNC 8060 Fagor Automation displays at the international fair is the ideal model for labour to machine due to its innovative ergonomic design with touch screen, integrated mouse, USB connector,... and a very visual navigation, with one operative that is really intuitive. Adapting to the needs of the user offers up to four ways of set pieces, and can even combine them between them.

- The language ISO standard to optimize the execution of parts.

- The parametric language for repetitive tasks on machines (allowing the user to create their own routines or cycles).

- The language ProGTL3, so that the user can schedule the shape of the workpiece simultaneously visualizing the geometry that is developing.

- IIP Interactive Language (Interactive Icon-based Pages) where the operator, through the use of intuitive cycles (without using the ISO language), defines the geometry of the part to be performed, the tool and machining conditions, and CNC takes care of the rest.

High-quality machining

It is usual to many parts to be machined to be generated in a Cad-Cam. CNC 8060 optimizes the number of obtained points smoothing trajectories through the creation of polynomials (Splines). This polynomial interpolation provides an excellent surface finishing piece and a high speed machining.

This functionality is integrated into the system of machining HSSA (High Speed Surface Accuracy) exclusive of Fagor, which offers a double benefit:

- Efforts that looks under the mechanics of the machine, are reduced which extends the life of its components,

- Thanks to the reduction of vibrations, smooth movements that allow for raising the value of the feed rate and reduce the error in the machining are achieved.

Prior to problems in the design of the parts

The Fagor CNC offer the possibility to perform a simulation of the piece with graphics of high resolution prior to its execution. The simulation allows to anticipate to possible errors in the programming which could damage the workpiece. These graphs are mainly used in two situations:

- Before machining: to verify that the programming is correct and prevent possible damage to the final piece.

- During machining: in environments of reduced visibility (by use of taladrina or chip, for example) where you can verify the actual machining status at any time.

The CNC8060 also allows, during the machining of a workpiece, the possibility to start preparing and simulating the following part, i.e., the graphics may be used simultaneously in execution mode and in the simulation.

Complex parts usually exist special features which are not significant with an overview. For these cases, is the possibility of cutting the workpiece with one or more sections to see the inside of the piece and verify in detail.

Solutions to unforeseen during machining

In machining of long duration, if unforeseen stops of the machine are caused by external causes (a power outage, a problem on the machine...), the recovery of the unfinished piece is very laborious.

The Fagor CNC help solve these incidents taking advantage of the performed machining and avoiding repeat the program. Simply perform a search of automatic block until the exact point of interruption and continue execution.

When imperfections seen in the area of disruption, you can simulate the program until an area next to the breakpoint and continue machining reviewing the damaged piece.

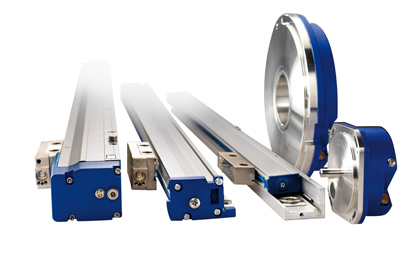

Fagor feedback systems

The firm displayed in EMO its complete range of absolute encoderes based on glass and strap up to 50 meters. New developments will be presented in the range that a resolution of 10 nm. In addition, absolute angular encoder of high resolution will be displayed up to 27 bits. In this quote Fagor Automation will have a space for the linear encoderes on strap up to 50 meters even with absolute technology, a brand that the company expects to overcome in new projects with customers. It highlights the new system of strap tension that allows the extraction of the head at both ends with the consequent savings in money and drastic reduction of the installation time and after-sales service, becoming more noticeable higher sea machine. Many customers worldwide have verified its extraordinary performance.

As a novelty, Fagor has managed to combine a product the extraordinary linear encoder Strip and absolute technology with 10 nm resolution.