Periphery decentralised, measuring and controlling in the zone of the µs

In spite of the clear evolution of the buses of current field still exist limitations of performance been due to the times of cycle (that although improved significantly because of the technology Ethernet still keep on being big for as which applications), that repercuten in the intervals of update. This is a key point to the hour to develop applications of critical time, that up to now were reserved only for systems of control centralised of high performance or complex and costly special solutions.

The temporary demands in the application of the periphery decentralised could easily attribute to two decisive factors:

- Time of answer: Which is the maximum time until an exit answers to a change in the entrance?

- Temporary accuracy/ Determinism: With which temporary accuracy can be detected an evento with regard to the accuracy in the exit activated?

The easiest method to reach improvements in both areas is the one to reduce the intervals of update, that already has been possible in the change of Profibus (minimum 600 µs) to Profinet IRT (minimum 250 µs), for example.

These improvements are not sufficient for some applications. Here, especially, it is convenient to have an a lot greater accuracy and therefore the application of the periphery decentralised of low cost excludes .

In this point the function marks of time in µs of the system SLIO could apply. SLIO ETS Offers a temporary accuracy improved significantly in the zone of the µs for all the bus systems of field.

The system Vipa SLIO

Mechanical

The system VIPA of And/S SLIO combines a high functionality with a concept of intelligent mechanics in a very compact design. SLIO Means Slice I/Or.

The system is extremely compact and adapts ‘module to module' exactly to the demands of the application. All the modules of interface (IM) for Profibus-DP, CANopen, PROFINET, Modbus and EtherCAT bear until 64 modules and have a module of feeding integrated .

The electronic modules (EM) feed through the modules of feeding (PM) and order in groups potentially separated according to requirements.

The electronic modules are connected with the modules of terminal (TM) through a mechanism of slide polarised. The module of terminal combines the terminal, the laimentación of the modules of electronics equipment dealers equipment dealers and the mechanics of the connector of bus. The creameros that have in shape of ladders allow a wired up fast, clear and sure. If necessary, it is possible to replace only the module of electronics equipment dealers equipment dealers simply extracting it of the terminal module - the wired up and the installation in the lane of 35 mm of profile do not see affected. This no only simplifies and accelerates the exchange of the modules, but it also avoids errors that can occur in the wired up of the And/S.

A precise allocation and the legibilidad of the state of the channel of the electronic modules guarantee by means of LEDs of integrated state and throw them of designation in the front. The visualisation contínua of the state of the module allows an exact location of the failure. This means that erroneous configurations, interruptions of bus, the failures of wired up and defective modules are showed by LEDs and can determine without tools of diagnostic.

back Bus

The fast 48 MBit/s of the back bus have developed regarding the maximum reliability and efficiency of the transmission of data, besides:

- Control of all the accesses

=> loss of module recognised directly

- differential Communication by current by signals of differential of low voltage (LVDS)

=> insensitive to the bad operation

- Function of watchdog in each module

=> Supervision of modules of interface and of the teacher of bus of field

- Hash total and counter of diagnostic in each module allow an exact diagnostic of the failure

=> fast location of failures of installation

- Flexible format of telegram and mechanism of transmission

=> optimum adaptation of the data of transmission in the structure of current system.

In addition to these basic functions of the back bus, SLIO also provides other elements that cancel the limitations of performance in the bus systems of existent field. With this the system decentralised SLIO develops also applications of field of critical time, that up to now were reserved only for systems of control centralised of high performance or complex special solutions.

Measuring and controlling in the zone of the µs

Vipa Already entered in 2005 a module of entrances that is compatible with CPUs STEP 7 for the systems of control centralised. This module measures the time of the transition of the condition of the signal with a resolution of 1 µs in 16 channels. A card of 8 channels of analog entrances with recording of data in 25 µs with mark of time in µs developed in the following year.

The functions are also available in a system decentralised and now extend of significant way: together with the launching of the system decentralised SLIO there are modules of entrances and digital exits with memory buffer (FIFO) for the flanks of signal. These terminal are marked with the acronym ETS (Edge Timestamp System).

Same time for all

In a Module of interface SLIO all the modules have the same time of base. This base of time has a resolution of 1 µs and a synchronism of module to module of +/- 85 ns. For Profibus DP-V2 (isochronous way) already is possible to synchronise the bases of time of several modules of interface SLIO and each module connected to a synchronism of +/- 5 micras. The mechanism underlying synchronisation is independent of the bus of field and will be available for other bus systems en el futuro.

Example: system of injection of fuel diesel

The following example of an electronic control of the injection diesel additional to optimise the combustion of a generator diesel of biogás gives an explanation of the operation and shows the diverse possibilities of application. The possibility to measurement and control exactly until the µs by SLIO ETS, offers now the comfort and the flexibility of a PLC that could combine with the standard process of the extremely exact injection of fuel in the stages pre, main and back to optimise the degree of broadcasts and the efficiency, doing without micro controller and special solutions.

The following description very simplified shows the function of control: The crankshaft (1) turns to 1.500 rpm in this field. Due to the fact that it is an engine of four times, the process of combustion only occurs 750 times by minute. Therefore, the tree of levy (2 and 3) to control the entrance and the exit of the valve only turns with 750 rpm. In one of the trees of levy there is a sensor of Hall, that sends an impulse to each turn of the tree of levy. This signal acts like a reference for the process of injection and is connected to a terminal of entrance of ETS SLIO. The injector of fuel diesel will be controlled electronically with a terminal of exit of ETS SLIO. The sensor in the tree of levy can be placed in such a way that the desfase between the signal of tree of levy and the sequence of injection of fuel are in a field of some 10 ms.

Realisation with standard terminals And/S via bus of field

If this task has to be resolved by standard terminals of And/S decentralised would be necessary to measure the time of the signal of entrance directly in the CPU. A series of inexactitudes resultarian here, what would cause a significant total error: ejemplarmente only describes the source of the greater error.

Supposes that the program of application of the CPU is able to measure the time with a sufficient precision (for example, SPEED7 CPU with 1 µs temporary resolution). The CPU controls if the evento of entrance (tree of levy) occur and saves the time. The CPU gives the order through the teacher of bus of field to the module interface and to his time to the terminal, when it is the moment to change the exit.

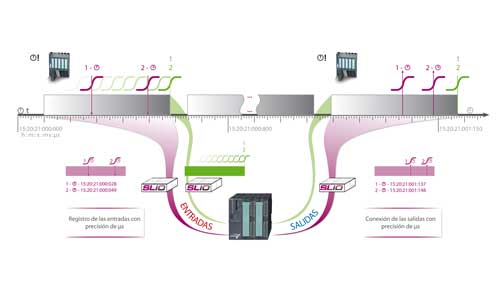

The green part of the figure 4 sample, that —in sight of the CPU— is not possible to distinguish the change of a signal in the cycle of the bus of field or more exactly, what demands the moment of the plot of bus of field. It presents a field of imprecision with the width of a minimum time of cycle of the bus of field.

Therefore, in a system Profibus with 600µs of time of cycle (better of the cases) results in an error of until 5,4 degrees to determine the position of the crankshaft (through the sensor of the tree of levy). 1500 rpm for a time of 40 ms by revolution and for an angular speed of 9 degrees by ms, mean that 5,4 degrees manage in 600 µs. More errors would appear when activating the exit.

With Profinet IRT and 250 µs of cycle the error would reduce to 2,25 degrees.

Because of these inadmissible errors these solutions are out of question. In the majority of these cases, apply the special control units of levy. But this solution supposes a high cost and results inflexible and bad of scalar when the adaptation and optimisation are necessary.

Realisation with terminals SLIO ETS via bus of field

When the terminal of And/S are able to measure the time of the flanks of the signal regarding the retardo in the conmutación of the exits until the time that the CPU defines, all the sources of error of the temporary precision of which are caused by the bus of field and the cycle of the CPU are deleted.

The violet part of the image 5 sample the big improvement of the temporary precision of said system in comparison with terminals of And/S without mark of time in µs- ETS (green).

So prompt like the terminal of entrance SLIO of ETS detects the evento of the tree of levy, saves incidentally the last state of the entrances and the time in the memory FIFO. These data are transferred to the CPU through the bus of field. The evento could classify now independently of the bus of field or the cycle of the CPU in base of the mark of time.

Because of the times of all the modules SLIO in a module of interface running the same to +/- 85 ns, the CPU is able to calculate the times of change for the exits of ETS SLIO (injector) with accuracy of until 1 µs and transfer the values through the bus of field. If the time of conmutación in the terminal has reached , the exits are controlled of suitable way and the resultant error is only 0,009 degrees.

Inside a cycle of bus of field until 15 requests of connection can send to a module ETS SLIO. Therefore, an exit could be controlled several times inside a cycle. The modules of entrance SLIO ETS have also a memory FIFO that it can store 15 entrances of data.

Through the application of modules SLIO ETS, for example, in a system Profibus, the errors of measurement could reduce to 1/600.

The times between the modules of interface of several SLIO could be synchronised exactly to +/- 5 ms in the equidistant operation DPV2 (isochronous). So it is possible also measurement and control with resolution of µs in the big installations decentralised.

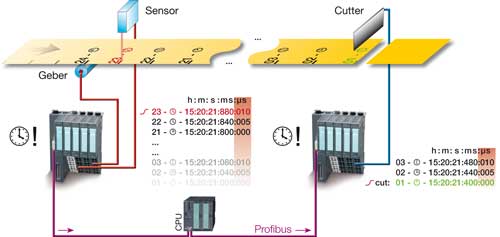

Example: Cortadora of paper

In the following example simplified of a cortadora of paper, shows the application of the same time of base with several modules of interface:

The detector for the recognition of the label and the codificador incremental are connected to each module of interface Profibus. The counter of SLIO for the codificador incremental provides a value to the µs in time of execution. This value allows to define easily the speed of the strip. The digital module ETS SLIO of entrance adds to the changes of the signal of the reader of the label a mark of time adjusted to the µs. The CPU can control the ‘cortadora' through a digital terminal of exit ETS SLIO gone out of form very precise, due to the fact that the second IM has the same base of time (maximum +/- 5 µs) that the first IM.

The following precisions achieve , at least, to the five metres by second: (Calculation simplified)

- Standard Profibus terminal: 600 µs: 3,000 mm

- Standard Profinet IRT terminal: 250 µs: 1,250 mm

- SLIO ETS Profibus terminal: +/- 5 µs: 0,050 mm

More functions

The function of mark of time also is available for the module of contaje SLIO and modules of SSI to do easily, for example, precise measurements of the speed. Also the analog modules of And/S offer high speed with mark of time and function by heart. Like examples of use, the generator diesel, whose electrical current has to be supplied of synchronous form in the system of supply of power. The exact synchronisation and the regulation of the tension of the line that is necessary for this end could do with terminals of analog entrance SLIO ETS. All the modules SLIO ETS can combine with modules SLIO standard for particular applications.

Conclusion

VIPA GmbH Offers with the system SLIO:

- A System of And/S with concept of labeling and mechanical oriented to the user

- Clear indication of state and diagnostic

- Technical of efficient connection in saving of space and time

- Reliable and fast back bus

- By means of the application of the function of mark of time ETS to measurement and control exactly to the µs, appear new fields of application for the programmable robots and bus systems of field, whose advantages are easy programming, flexibility and ease of maintenance, but that were reserved for special solutions up to now.