Maquinaria Termo Plásticos, S.L. (MTP) - Dosing for plastics

Moretto DMG

Dosificadores gravimétricos

The dosificadores gravimétricos of the series DGM, integrated cheese cheese by five series and 115 models, are machines of high technological content. Thanks to his exclusive solutions, ensure high level performances until in the most laborious uses and with levels of incomparable precision. Hoppers in stainless steel, mezclador electrical and digital technology only with some of the a lot of advantages that offers the series; valve of double lid and hopper in heavy free are other endowments that do that DGM was one of the most advanced systems.

The valve of double lid is the mechanism in that it bases all the system DGM. The speed of reaction of 40 thousandth of second can not be perceived by the eye; a so high speed is the technical condition that allows to obtain a high level of precision. The hopper of weighed is not connected to any mechanism, wire or pipe for the air compressesed; of this way the heavy will not suffer any external interference and the values will be effective and in accordance with the calculated by the microprocessor of control. The degree of precision is of 99,998% in the time measure. The sophisticated endowments allows that the series DGM weigh one hundred times by second, processing the heavy and selecting with spice s algorithms praise 4 heavy more significant. Besides, the digital technology allows a greater tolerabilidad to the temperatures, keeping a constant control until during the treatment of hot materials dried.

The DGM can be inspected entirely, without using any tool; this allows that each operation was very simple and effective.

The mezcladura is the final phase of a good dosage for the manufacturing of the mixes. In the DGM the mezclador comes accionado by means of a motoreductor electrical and the camera of mezcladura this done in stainless steel. The spherical form deletes the risk of stagnations, completing like this in optimum way the manufacturing of the mix.

Each model has four types of hopper, instrumented with the system of valve or double lid. It stands out Rotopulse, the hopper with exclusive system of microdosificación that can control 0,1 grams of dosage.

In addition to the 115 models has of a version for high temperatures and white camera.

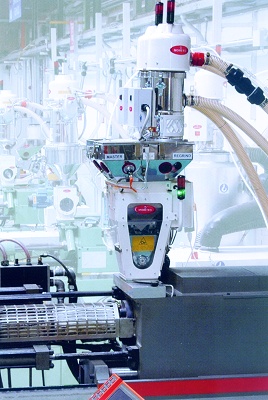

It can be used directly on of the mouth of presses. Several applications can accompany this machine as for example, the separador magnetic, the valve to butterfly or guillotine, a base for the mezclador supplementary for the subtle dispersions. When there are significant quantities, DGM can be installed in earth, on of a chassis with a special tank of aspiración.

The valve of double lid is the mechanism in that it bases all the system DGM. The speed of reaction of 40 thousandth of second can not be perceived by the eye; a so high speed is the technical condition that allows to obtain a high level of precision. The hopper of weighed is not connected to any mechanism, wire or pipe for the air compressesed; of this way the heavy will not suffer any external interference and the values will be effective and in accordance with the calculated by the microprocessor of control. The degree of precision is of 99,998% in the time measure. The sophisticated endowments allows that the series DGM weigh one hundred times by second, processing the heavy and selecting with spice s algorithms praise 4 heavy more significant. Besides, the digital technology allows a greater tolerabilidad to the temperatures, keeping a constant control until during the treatment of hot materials dried.

The DGM can be inspected entirely, without using any tool; this allows that each operation was very simple and effective.

The mezcladura is the final phase of a good dosage for the manufacturing of the mixes. In the DGM the mezclador comes accionado by means of a motoreductor electrical and the camera of mezcladura this done in stainless steel. The spherical form deletes the risk of stagnations, completing like this in optimum way the manufacturing of the mix.

Each model has four types of hopper, instrumented with the system of valve or double lid. It stands out Rotopulse, the hopper with exclusive system of microdosificación that can control 0,1 grams of dosage.

In addition to the 115 models has of a version for high temperatures and white camera.

It can be used directly on of the mouth of presses. Several applications can accompany this machine as for example, the separador magnetic, the valve to butterfly or guillotine, a base for the mezclador supplementary for the subtle dispersions. When there are significant quantities, DGM can be installed in earth, on of a chassis with a special tank of aspiración.