Siemens, S.A. - Smart Infrastructure - Security, surveillance, SCADA, HMI and monitorization software

Siemens Simatic AC MP

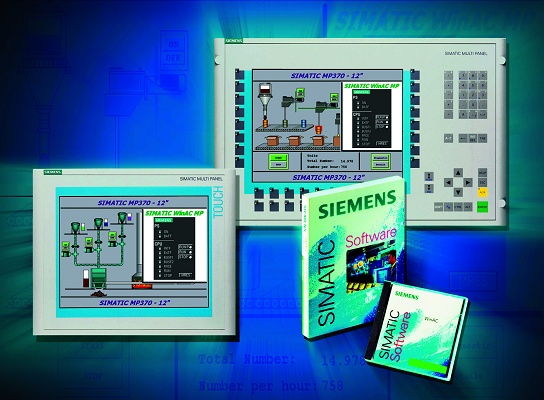

Control and visualisation by software: using a platform multifuncional

The PLC in format software Simatic AC MP allows to resolve for the first time to level of software tasks of control and visualisation from a platform Windows CE. WinAC MP Of the division of Products and Industrial Systems of Siemens is executable in the platform multifuncional Simatic MP 370 and serves especially for tasks with a lot of data. The MP 370 does not have hard disk neither fan, and offers capacity of real time and answer determinística. With this, this platform offers, on the one hand the flexibility of the PCs and by another a robust hardware to all proof.

The code of Win AC MP is compatible with the one of the PLC Simatic S7; program with the standard software Step 7 of Simatic. The programs for WinAC MP can use also for S7 and other products of the range WinAC. The surroundings of development unified for the different platforms of control allows big savings in time and costs of engineering.

The applications of visualisation that run in the MP 370 create with the tool of configuration Simatic ProTool. Applications already done can expand easily with functions for WinAC MP. To be able to handle and visualise the functions of control in the MP 370, ProTool has of functions WinAC MP additional such as Run, Stop and Mres. The flexible functions of available extension, for example components ActiveX in ProoTool, allow to customise the functionality of visualisation to taste of the customer. This materialises with the Software Development Kits.

The communication with the level of And/S establishes through the interface master Profibus DP integrated cheese cheese. The port Ethernet also incorporated allows to download projects ProTool and Step 7 through a network, using the protocol TCP/IP.

The possibility to change functions of control and visualisation in a same platform reduces the number of components of necessary automation and, of this form, the cost of the system. Thanks to the compact construction reduces the necessary space in the electrical cupboard as well as the costs of setting and wired up. This simplifies the structure of the system, accelerates the set up and optimises the technical service, since so much for the gestión of spare parts as for the functions of diagnostic only is necessary to consider an alone type instrument.

The code of Win AC MP is compatible with the one of the PLC Simatic S7; program with the standard software Step 7 of Simatic. The programs for WinAC MP can use also for S7 and other products of the range WinAC. The surroundings of development unified for the different platforms of control allows big savings in time and costs of engineering.

The applications of visualisation that run in the MP 370 create with the tool of configuration Simatic ProTool. Applications already done can expand easily with functions for WinAC MP. To be able to handle and visualise the functions of control in the MP 370, ProTool has of functions WinAC MP additional such as Run, Stop and Mres. The flexible functions of available extension, for example components ActiveX in ProoTool, allow to customise the functionality of visualisation to taste of the customer. This materialises with the Software Development Kits.

The communication with the level of And/S establishes through the interface master Profibus DP integrated cheese cheese. The port Ethernet also incorporated allows to download projects ProTool and Step 7 through a network, using the protocol TCP/IP.

The possibility to change functions of control and visualisation in a same platform reduces the number of components of necessary automation and, of this form, the cost of the system. Thanks to the compact construction reduces the necessary space in the electrical cupboard as well as the costs of setting and wired up. This simplifies the structure of the system, accelerates the set up and optimises the technical service, since so much for the gestión of spare parts as for the functions of diagnostic only is necessary to consider an alone type instrument.