motan-colortronic Shows the system of dosage and mixed Ultrablend 95 during Medtec

The Ultrablend 95 offer clear advantages to the manufacturers of thermoplastic medical devices. The processing of compounds of prime matter that sometimes are extremely expensive in operations higiénicamente clean (possibly also in white rooms) in primary packaging, components, implants, instruments and medical equipment requires the highest levels of cleaning, precision and discipline regarding costs.

The manufacturer of medical devices

The mezclador gravimétrico Ultrablend has been developed for dosage and mixed of precise and continuous way of raw materials that flow freely: additives and granulated of plastic. It improves the quality and the stability of the process and contributes of by yes to minimise the costs of production. With the design of stainless steel electropulido, motan has put a big emphasis in clear functions, a minimum maintenance and an easy operation in some surroundings of production higiénicamente clean.

All the hoppers of material and cameras of mixed have been designed without any “dead zone”. All the boards are entirely soldered. Like result, can not accumulate any residual quantity of material and therefore it deletes the pollution of subsequent batches.

The Ultrablend 95 is especially adapted for a precise dosage of quantities extremely small of material directly in the machine of moldeado by injection, extrusion or moldeado by blown. It can dosificar a maximum of four components of prime matter by weight, one after the another, of way so precise as it require it the formula. To continuation mix homogéneamente in the camera of mixed successive (volume of 4,5 litres) and feed by the mouth of feeding of the machine of processing. The minimum quantity of dosage is 3 g by component (size of batch of 900 g).

When they use two components can attain a maximum production of 260 kg/h. This unit gravimétrica of dosage and mixed is ideal for applications with frequent changes of material: all the pieces in contact with the product can withdraw and clean quickly. Besides, the control deslizante of dosage remains closed during the change of material, not even the most minimum quantity of material can escape neither go out. The principle of cell of individual load compensates any vibration of the machine of processing. This guarantees the maximum precision in the weighing.

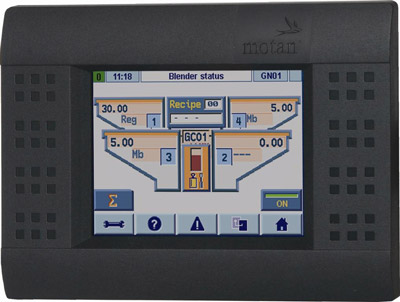

The system of control GRAVInet uses to control the unit Ultrablend. The screen to all colour allows to operate through menus in a tactile signpost. Thanks to the technology integrated cheese cheese Ethernet, the operation also can llevar by means of a WEBpanel of motan or a PC from any place that wish . It exists a control of transport for until seven loaders of integrated cheese cheese material of series in the control GRAVInet.