An environingingment ‘Premium' in the interior of the car

The technician of the sobremoldeo of decorative films has come under scrutiny of a lot of technical conversations along the last years, especially in relation with applications for the interior of the car. The observers interested of the profession could carry the impressesion that the future belongs to the increasingly perfect imitations of surfaces of natural materials and his processed automated to realise decorative pieces. However, a visit to the factory eslovena of the German supplier of the car and specialist in surfaces Novem forces to put this impressesion in entredicho. Because here, the paper of protagonists do not have it the decorative films, but exquisite pieces of enchapados wooden of all the parts of the world or fabrics of fibres of carbon, as well as the skill in the manual work to realise them (photo 1). The exquisite feeling reinforces even more if the decorative pieces find in some surroundings of applications of leather and textile (see photo 2).

This type of decorative pieces of high value find in the series of more quality and even of the half models of practically all the manufacturers of trucks. Besides, it discerns already a tendency to use them like option in small trucks and of half class.

But what is unavoidable is that the quality Premium requires a work of quality. In spite of all the technical possibilities of our times, the manufacture of a wooden decorative piece requires a big quantity of manual works specialised (photo 3).

The injection and the manual work

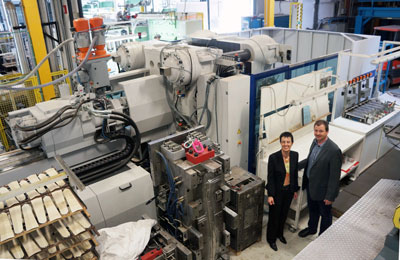

The enchapados and the fabrics require an accurate manufacturing and have his own life. Before his processed in the inyectora stabilise by means of diverse works (cutting, compressesion, laminación with layers...) But his placing in the cavity of the mould requires the experience and the manual skill of an operario. This is like this because the preformas wooden depend when purchasing his form of the environingingmental conditions, by what need an adjust in his placing and positioning in the mould. With a robot this operation would be excessively costly, as also they would be it the costs of programming and of adaptation, because of the big quantity of variants. Another peculiarity of the production in Novem is that, when it treats to purchase an inyectora, the most important is not the aprovechamiento of the strength of closing, but the ergonomic conditions in and around the unit of closing. The manager of applications of Novem signals in this regard: “For us that a machine was compact is decisive and this is especially true in the surroundings of the mould because the operario has to goes in in the unit of injection in each cycle of production. Our exigencia was that this could do in an alone level and without difficult movements. The process of placing of the preforma is decisive for the quality of the final product and therefore it does not have to have limitations. In this sense want to stand out the excellent collaboration llevar with the team of designers of Battenfeld and his creative contributions to improve the ergonomics of the machine” (Photo 4).

After a process of accurate selection by part of Novem, decanted finally by a MacroPower of Battenfeld, and more in concrete by the model 1100 / 3400. His distance between columns is of 1.450 x 1.100 mm, that provides the suitable space for the timely manipulations. On the contrary that the ‚‘generosity' contributed with the unit of closing, with the unit of injection decanted by the type 3.400 with husillo of 65 mm that corresponds with the low weight of injection of the pieces of injection.

Eases for the change of variants

An advantage of the big machines of Wittmann-Battenfeld is the scarce length of his columns. It is the result of the integration of these four elements of closing in the structure of the mobile plate of the machine, in place of his positioning in the external part of the plate, as it is used to to be usual. When the plate realises his complete career until his final position in the limit of the bancada generates a free space between the final extreme of the columns and the plate of the machine, that can be used for the change of mould so much from up as from the side. By the contrary, with the elongation of the bancada of 400 mm the free space between columns and plate increased until the 1.000 mm, which supposes a big advantage for the lateral change of the mould taking into account the scarce height of the industrial pavilion in which it situates the machine.

The production in the company Novem is an excellent example of the importance of a place of work in which the ergonomics facilitates the relation man-machine. Like this it expresseses it also Peter Ade: “After some years without being it, have gone back to be customers of Battenfeld, precisely because the concept of the MacroPower answered totally to our need, in addition to adjusting to our space of production when being a so compact model” (photo 5).