This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Entrevista a Víctor Oliveira, administrador y director general de MoliporexInterview with Victor Oliveira, administrator and CEO of Moliporex

"This new reality points to a need for systematic innovation, optimisation of process and commercial aggressiveness"

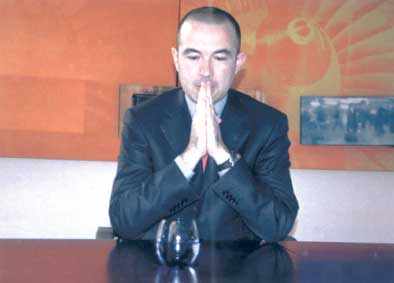

On the walls in bright colors of the plant of Moliporex in Marinha Grande you can read quotes of famous writers such as Victor Hugo that in some way summary this company moldista company's philosophy. Structured with good taste, each Department of the plant maintains a focus on design thanks to Victor Oliveira, administrator and CEO of Moliporex.

How many people work in the company? when was created?

The Vangest group is a business group that currently adds 16 companies that respond in an integrated manner in a philosophy of complementarity to the complete cycle of the product development. Taking culture based on the plastic by inherence to the fact that we originally exclusively moldistas, today Vangest group has a unique transverse offer from design to the piece of plastic engineering, prototyping and mold prototype or mold production.

Founded in 1986 the group now has 250 employees direct crossing to subcontracting projects and their specialties in a network of partners qualified and approved according to the most high quality parameters.

What kind of moulds are manufactured?

Offering a wide range from highly technical moulds up to large moulds, Vangest group is prepared to respond to needs of large projects from the automotive industry to consumer goods, electrical appliances, packaging, electronics, among others.

If you are a subcontractor and does not have own product, what are the main sectors to which it is addressed?

The main sectors in which we are today, the automotive, electronics, household appliances and packaging.

There are many differences between each sector customers quality requirements? What make the difference?

What makes the difference is essentially the level of project and the culture of the company's quality that can be adapted to different types of moulds regardless of the sector for which it is intended. This philosophy enables us to develop and manufacture moulds for different sectors in response to the highest levels of demand.

What has been the evolution of the industry and your company during the last years?

The evolution of the sector and especially in our company allocates to an offer every time but transversal with increasing added value. In reality our Group has gone transforming in the last 6 years of a moldista conventional to an entity with the capacity to offer to the global market an integrated service. In this logic follow thinking that the cooperation inter business is fundamental, considering that customer and supplier have to assume increasingly a posture of association and cooperation.

What threats or difficulties faced by the sector today?

The sector is facing threats increasingly more evident relating to price and time of execution. This new reality points to a need for systematic innovation, optimisation of process and aggressive commercial repositioning an industry that until now was devoted exclusively to respond to a specific need of the development of a product cycle and now has to increase the value of its offer.

It performs all the machining or subcontract part?

Part of the work of machining are outsourced but always control processes and quality of our company.

With what machinery park account to make the molds?

In our workshops in Portugal we currently have 9 3 and 5 axis high speed machining centers up to 3,600 mm travel All our centres of machining are Deckel Maho of origin German brand.

In addition to these, we have a machine park of electro erosion of penetration and piped Charmille, Agie and Fanuc.

We also have the typical equipment of conventional milling rectification, quality control, reverse engineering (digitized laser), presses for adjustment and injection moulds produced test machine.

In addition, we have internally exclusively devoted to the rapid prototyping machines - 1 machine STL, 3 machines for production of moulds of silicone, 1 machine of RIM, Department of painting of prototypes between other complementary means.

It also carries out engineering? What technical and human resources does?

Our activity is strongly founded and is based on engineering. Engineering internally understand mold draft, but also and mainly of piece. This is one of the aspects in which we have a strong commitment, more and more us involved with our clients on the part of design, engineering, prototyping and moulding.

Systems of CAD/CAM/CAE we use are mainly Catia and Unigraphics, trying to adapt the system we use to the requirements of the customer and the particularity of each project.

In the field of CAD, CAM and CAE today have a total of 93 posts.

He also built special moulds?

We develop solutions tailored to the customer even that is not standard or are not available in the market regardless of the level of complexity.

Do they have injectors for testing of injection?

We internally have a machine fuel transfer Engel for the testing of our molds.

For which geographical markets do they work? (percentage of molds for Spain)

We work for: Benelux, Brazil, Canada, Spain, Finland, France, Germany, England, Iran, Israel, Mexico, Norway, South Africa, Sweden, Switzerland, Turkey and EE.UU. In Brazil we also have a workshop of molds that works primarily for the automotive industry.

The Spain market today accounts for 10% of our turnover.

How was the last year for the company?

It was a year of evolution at the level of growth, important in the line of cooperation with our customers and at the level of development of integrated solutions to what has allowed us to grow in a year of economic decline.

Where you think that you must move a company like yours to improve business?

The quality is today a key factor in the supply of any company in this business area. We continue to believe our integrative strategy is fundamental in the way that we determine to follow.

The "time to market", i.e., the time shorter than the market requires to get out more and more products with also shorter life cycles, today makes us ask ourselves seriously the optimization and re-engineering of processes and mediathat they allow us to continue and consolidate our position as market leader.

Related Companies or Entities