Europe is moving towards high-value applications

In Europe, is to be noted that Germany is a stable market, which highlights the fact that standard machines are already a hole with difficulties, because standard applications are moving to the countries of Eastern Europe. On the other hand, the sector is growing in systems and automation.

A country back is the United Kingdom, where the situation is very complicated, contrary to what is happening, for example, in Russia, which is a positive development. United States, stable, but to the floor, and South America, with markets in retreat, they draw a grey panorama on the American continent.

Often refers to the importance of providing technologies for high-value applications in Europe, but rarely contribute data. Well, in 2003, a total of 70.600 machines sold worldwide, 8,700 were deployed to high-tech applications. And we know more: 17,800 was for technical parts, 12.300 to 'commodities' and 31.800 to applications of the low range from a technological point of view. The Outlook for 2007 is that of high technological value from rising to 12,500 (out of a total of 74.400) and those of low value reduced to 29.400.

By continent, the figures denote one more than likely transition in Asia to high value applications. In fact, if in 2003, a total of 55,000 injectors sold in Asia, 5,600 went to the 'high tech', in 2007 it is expected the figure to rise to 8,300, being the total of 58.300.

In Europe, last year went to high value applications 2,500 machines (out of a total of 10.300), while in 2007 it will be up to 3,200, on a total of 10,800.

What do customers want?

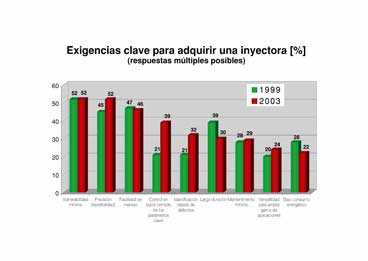

- Increasingly, purchasing decisions are prioritizing the precision and the absence of problems during production.

- One of every three transformers has had to increase the frequency of change of molds in the last ten years, even reaching daily changes.

- Four out of every six criteria used in deciding a purchase are related to issues relating to the service.

- The availability of long-term spare parts has become something more important than ever, even at the time to maintain the loyalty of the client.

In addition, the requirements which European transformers start when planning the acquisition of a new fuel transfer have varied, sometimes only in nuances but very significant, from 1999 to 2003. One of the most noteworthy changes is the different attitude towards the consumption of energy, an issue that is in the crosshairs of the industry since the most of the builders of machines offer fully electrical equipment. Therefore, if in 1999, the low energy consumption was appreciated by a 29 per cent of the transformers, in 2003, the percentage fell to 22 percent. It has also decreased the importance given to the length of the machine (a 39 to 30 per cent).

The most dramatic increase is that of control in closed-loop of the key parameters of the machine. If in 1999 a 21 per cent considered it a relevant factor, now the percentage has risen to 39 percent.

The most valued criteria are the vulnerability of the machine (52 per cent cited as elementary in 1999 and the percentage has remained unchanged), the precision of the repeatability of the machine (45 per cent in 1999 and 52 per cent in 2003) and the ease of handling (47 per cent in 1999 and 46 by) (% in 2003).

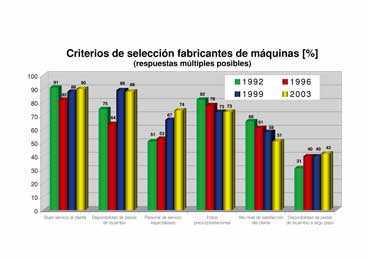

The criteria that the transformers follow when choosing a provider have also been analysed, since 1992. Head, keeps since then service the client. Followed by the availability of spare parts, a parameter that is increasingly valued (88 per cent of the transformers in 2003, compared to the 76 of 1992).

| The world market in 2003 and 2007 (in units of machines) | |

|

2003 |

|

| High technology and specifications | 8,700 |

| Technical moulding | 17,800 |

| Commodities | 12.300 |

| Low specifications | 31.800 |

| Total | 70.600 |

| 2007 | |

| High technology and specifications | 12,500 |

| Technical moulding | 16,700 |

| Commodities | 15,800 |

| Low specifications | 29.400 |

| Total | 74.400 |

The criteria that the transformers follow when choosing a provider have also been analysed, since 1992. Head, keeps since then service the client. Followed by the availability of spare parts, a parameter that is increasingly valued (88 per cent of the transformers in 2003, compared to the 76 of 1992).

Some of the recent examples

The manufacture of pipette tips requires a technology of injection without flows with a high-value precision mechanics. The reproducibility must be above average, with minor variations possible between the weights of the various pieces. They are characteristics that responds totally electric injectors of Battenfeld EM series. At the K 2004 produced pipette tips of polypropylene in a B4 Unilog EM1000/210 with a cast of 34 cavities of the Tanner company. The energy requirement has been clearly by 20% when the machine movements are continuing. Energy savings of up to 50% can often be achieved.

In addition, it showed the versatility of the C3 Sprinter series with the help of two examples. On the one hand, with the use of moulds of flats, this series meets high performance requirements with regard to plasticizing capacity and weight of the moulds. On the other hand, the C3 series is used for the first time for the technique of several components. With the help of a 600-3500 C3 KM, Krauss-Maffei announced the production of packaging for food with a cast of floors with reduced cycle times. As an example of application, during the fair was used a container of food with a volume of approximately 550 ml.

| 2003 | |

| High technology and specifications | 2,500 |

| Technical moulding | 5,700 |

| Commodities | 2,100 |

| Total | 10.300 |

| 2007 | |

| High technology and specifications | 3.2 |

| Technical moulding | 5,500 |

| Commodities | 2,100 |

| Total | 10,800 |

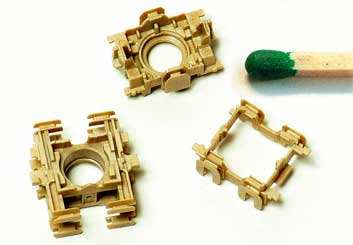

Engel (in Spain, Helmut Roegele) is also providing interesting examples, some of them with technologies of fashion. Such is the case of the injection assisted with water, where his Watermelt technique reduces the cycle of 40 to 70 percent from the injection assisted with gas. Like many of its competitors, Engel acts with intelligent solutions in other fields of injection, as the plural-component parts, but the X-Melt technique is perhaps less well known. An example: the Austrian company High Tech Plastics (HTTP) could not have made the support of the lens of a head of laser of a DVD player without the X-Melt technique. Produced with a 30 percent cut fibre in LCP, the two pieces of extreme complexity for the read head weighs only 115 mg and 50 mg respectively. The complexity and the thinness of its projections as well as the requirement of the absolute precision of an injected to another, make that the machine should operate with a very narrow window of processes. A classic micromoldeo system cannot meet these requirements, as indicated in Engel. The X-Melt process (injection through expansion process developed by Engel to standard machines) enables the injection of these pieces. HTTP uses a 200/55 E-Motion with 55 tonnes of clamping force to do so. Thus, the investment of a specific machine for micromoldeo, at the same time maintaining the accuracy of the electric machines Engel has saved.