Direct drives begin to accelerate

Thanks to these innovative companies, knowledge of linear direct drives has increased dramatically. Business figures increase steadily at the same time that, as a result, prices fall. As it increases the number of facilities, is also more technology development and the diversity of products. Frank Wittig, engineer for the application of GE Fanuc Automation Europe, says: "five years ago, in the production of linear motors in Fanuc manual labor was still used. "Today the production is fully automated through the technology of industrial robots and all that this implies."

Motors-linear in all sorts of power and dimensions

Frank Wittig describes the usefulness of your application in the following way: "In comparison with a rotating ball spindle motor, linear motor offers advantages such as acceleration and high speed, minimum wear and high accuracy." Given that the linear motors are directly integrated in the mechanical system, they do very precise movements. The elements of transmission as transmission units and spindles to balls are not at all necessary. Especially in machine tool machining speeds exceeding 5 m/min, is obtained greater precision of contour.

Resistance to wear and tear through maintenance

Frank Wittig considers the machining of light alloys as the ideal application for linear motors, as they are not attracted by magnets and require high speeds. Fast and long axis movements show particularly clearly the advantages. But the short and permanent movements provide also interesting examples, as Frank Wittig explains: "One of our clients uses a machine grinding machine to produce drills for circuit boards printed with a diameter less than 0.5 mm." The grinding of the tip of the drill only requires a very short axis route. If a conventional solution with a spindle mechanism is used, the permanent movement along the same length of the spindle will do that it should be replaced at least every two years due to wear. "This is an ideal case for the linear direct drive."

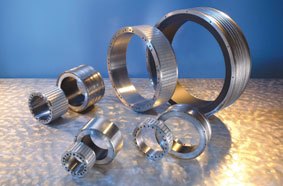

Couple for rotary tables and inclined axis drives

The engine's torque is much more rigid and, like its linear counterpart, does not require maintenance. It offers greater accuracy and can transmit a torque high due to the large number of magnets. "The advantages of a couple engine are so obvious that our clients are more easily convinced that with linear motors," adds Frank Wittig.

The par servo synchronous of Serie D, introduced by GE Fanuc at the end of last year, are primarily designed for customers in the segment of the machine tool. Through the use of powerful rare earth magnets, it is possible to achieve a high torque at low speeds with high angular accelerations.

Depending on the model, the maximum torque is 85Nm-3000Nm. The maximum speed is 75 rpm and 400 rpm, with a very small pair fluctuation. Versions 200Vca and 400Vca are available. These features make them ideal for rotary tables or axis of turning additional, revolver lathes and carving of gear machines.

Other technical details are: the version of 400V of the model of the upper end of the range D3000/150is generates a continuous pair of 1200Nm at speeds of up 150rpm with liquid cooling. The stator with cast coil can be equipped with a cooling jacket. They can generate pairs of 3000 Nm with speeds of up to 150 rpm. The engine has only 160 mm in height; the outside diameter, including the cooling jacket, is 565 mm.