Wittmann Battenfeld Presents inyectoras of high technology for the American market

The group Wittmann has been working of satisfactory form in the North American market during a lot of years. Especially, the new machines of Wittmann Battenfeld Series Power have gone in with big strength in the American market, affirm from the group.

These machines, with his big energetic efficiency, combined with the automation of high technology and peripheral equipment, as well as the last technology applied for maximizar the profit of the customer, will be one of the strong points of all the exhibitions of the NPE this year in Orlando.

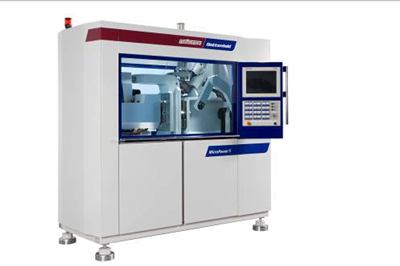

Will expose a big variety of the Series Power, including the MicroPower, the machine of high precision for the micro injection of plastics, the EcoPower entirely electrical and the big model of the series, the MacroPower. The machines of the line Power offer high precision, compact design, maximum ease for the user, modular and big concept efficiency energetic.

In the MicroPower 5/3 will inject in POM a micro connector of 28-pines of dimensions 6,1 x 1,2 mm and with a weight of 3 mg. The micro connector will be manufacturado with a time of inferior cycle to the 4 seconds, in a mould of 2 cavities supplied by Zumtobel. The pieces will be extracted by a robot Wittmann W8VS2, will happen to an integrated cheese cheese camera inside the cell of production and afterwards to the system of control of the machine for the inspection of quality. Later the pieces will separate according to the cavities and apiladas in the module of apilamiento. In addition to the robot, a dryer of material Wittmann, a controller of temperature and a feeder will be integrated cheese cheese to the machine as well as also the system of control Unilog B6, forming like this a complete cell of production.

The functionality of the EcoPower will be will show with two machines of this series with strengths of closing of 110 tonnes. In an EcoPower 110/130 will manufacture the frontal signpost of a cafetera in a mould of an alone cavity supplied by Wittner.

Also will be integrated cheese cheese in the machine a robot Wittmann for the extraction equipment equipment of the pieces, a band transportadora and a peripheral team. This piece with brilliant surface in the visible face will produce in PC/ABS. The pieces inject by means of a process variotérmico using the technology BFMOLDTM. In this technology, all the space that remains underneath of the cavity uses to heat and refrigerar. This allows, above all else, a fast cooling of the area of the mould. So this technology is not interesting only to reduce the cycle of time, but also it is it to warn the deformation by the high temperatures and reduce tensions. Besides, can warn the marks of sinking and the lines of welding by means of the help of the technology BFMOLD, sobretodo in the components with a visible or expensive surface with brilliant surface.

The big machine MacroPower, machine with mould of Haidlmair.

The pieces will extract with a robot Wittmann W818, which will happen them to a camera for a superficial inspection. The system of inspection of the pieces exposed in this line provides a method to identify superficial defects, independently of the human observation.

This system, developed by PCCL (Polymer Competence Center Leoben), does photos of the surface of the pieces and compares them with photos of reference. This system allows a detection of superficial defects to 100%, independently of the presence of a human observer.

In the second EcoPower, the EcoPower 110/130, manufacturará in ABS a device of closing for the folding tables that can find behind the seats of the aeroplanes in a mould of two cavities with a time of inferior cycle to the 30 seconds.

Will use a robot Wittmann W821 to collect the pasador metallic to attach the lock to a camera, to check his rectitud, and later places in the mould for the moldeo by insertion. The robot also will extract the pieces finalised, will place them in the second camera to check his length and afterwards will deposit them in the strip transportadora.

The group wants to show the functionality of the MacroPower sen the NPE of Orlando by means of an example of the one of the industry of the packaging. It will manufacture a folding box in PP in a MacroPower 850 XL/8800 with a mould provisto by Haidlmair. The pieces will extract with a robot Wittmann W843 and afterwards will be assembled in the station of assembling and finally will fold and apilarán. The MacroPower 850 XL is the version with dishes expanded of the 850 t, with a distance of 1475 mm x 1125 mm between columns.

Besides, the process IML also will star the fair with a machine TM Xpresses 160 in a hybrid version. They will produce tubes for butter, with a capacity of 125 g and with a thickness of wall of 0,35 mm, in PP in a mould of 2 cavities. The insertion of the labels and the extraction equipment equipment of the pieces finished will carry it out a robot Wittmann W827, with a total time of cycle of 2,8 seconds. The unit of production is instrumented with a system of the signature Eisbär. A special characteristic of this application is the new line modulate IML with a package of high performance and a system of integrated cheese cheese control CNC8, that offers a series of advantages. The integration of the system of control allows a direct operation through the machine of injection; the times of intervention reduce of a substantial form by means of the function of “intelligent extraction equipment equipment”.

The exhibition programmed in the stand of Wittmann Battenfeld culminates by means of the presentation of his service Web 24/7, now that it already is working all over the world. The service web 24/7 represents the on-line service of the company, which is available to all hours the 7 days of the week. For the machinery instrumented with the system of control Unilog B6 based in Windows XP, the service web offers the possibility to the customers to contact by telephone with a technician qualified anytime. Through Internet, obviously under the approval of the customer, the technicians can connect directly to the machine or the robot Wittmann integrated cheese cheese.

TM Xpresses With equipment IML.

In addition to the exhibitions in the stand of Wittmann Battenfeld, another machine will exhibit in the stand of Wacker Chemical Corp., in the stand number 58013, specifically a machine of injection multicomponente HM 180/350H/350V ServoPower. The process IML will show with the injection of one founds of glasses in a mould of 2 cavities provided by Rico. This founds of glasses is of 2 components done of the combination of thermoplastic material (PBT 20% FV) and LSR.

The pumps of dosage and mixed will be supplied by 2 KM. The controllers of temperature Tempro plus D will use to generate the high temperature required in the mould, for vulcanizar the LSR. The machine comes with a package of equipment for the processed of the silicone (unit of special injection, team of empty, etc.). The rotary presses table servo motorised is integrated cheese cheese in the machine. The pieces will manufacture in a mould of cavities 1+1 with an inferior cycle to 50 seconds.

Automation of Wittmann and peripheral equipment

Besides, Wittmann Battenfeld presents a wide range of robots and peripheral equipment for autonomous solutions.

In the area of team of automation, the company will exhibit a representative section of his range of robots servo of the series R8.2, including the small model W818, as well as robots of the series Ultra-High-Speed (UHS) and also a big robot W873 with a capacity of useful load of 125 kg. The different robots will join and will expose in an operative cell to show the functionality of his systems of control in applications of the world of the sport.

The new model of robot W818 with a manipulation of maximum load of 6 kg deserves a particular attention. The maximum vertical trip can be of 1.200 mm. The device is instrumented with 3 powerful servo motors and coding absolute for all the linear axles like standard. The rotary presses axis servo motorised optional allows a big variety of new functions. The servo axis B is able to turn of continuous form the pinza and the axis giratorio C from 0° to 270°, whereas the servo axis C turns the pinza of 0° to 180°. All the intermediate positions of each rotatory axis can be programmed with a precision of 0,01°. These rotational axles, combined with the module of planning of route TruePath of the system of control of the Wittmann R8.2, allows movements with a precision of coordination in any conceivable steering inside a three-dimensional space, including the boundless possibilities for the parallel movements of the linear and rotational axles.

In the field of the peripheral equipment will exhibit the dehumidifiers of the series Drymax, feeders Feedmax, the systems of dosage gravimétrica of the series Gravimax, controllers of temperature of the series Tempro and mills of the series BUT and MC, as well as the Great mills.

Of all the dehumidifiers, the new team of dried by wheel Drymax Aton would have to receive a particular attention. What does so special to the Drymax Aton is the combination of a point of constant condensation with a big energetic efficiency and at the same time with some costs of maintenance very low. All these advantages have been able to achieve thanks to the use of an innovative wheel of dried, that consists in a number of cameras that go filling freely with balls desiccants. This concept of filled favours a very low cost of maintenance of the wheel.

Of all the feeders, the new loaders of material Feedmax B for systems centralised is of special interest. These are particularly easy to use and perfectly adapted for all type of applications.

Of all the atemperadores, the new Tempro plus D series deserves a special comment. The controllers of temperature Tempro offer the highest standard stability together with an optimum management of works, and besides offers a clear and complete visualisation of all the process, allowing like this a boundless control of the system.

With the introduction of the new series of equipment Tempro plus D, one generously dimensionada screen LCD of 5,7” to colour provides the visualisation. There are several buttons in the screen that can be configured with complete freedom to be able to achieve the information wished in each concrete case.