Siemens PLM enables a successful transition from manufacturing to design

July 11, 2011

When Sapa Placencia established centre of excellence, it changed its mission and decided to specialize in product design. Previously, the company had experience only in the textile industry, after having successfully designed six types of looms. Mikel Onandia, Izaguirre, PID engineer, explains that he became an a time when the company decided that he no longer wanted to be a single manufacturer. "About five years ago, we only dedicábamos to manufacture products under license and what we diseñábamos were looms", explains B..

"It was then that she began designing an auxiliary unit of energy." PID mission is to improve the competitiveness of the client through applied research and development of technologies and systems. Innovation is your starting point and its objective. "The client requests a series of updates to products and innovations and PID presents a proposal, sometimes in conjunction with other companies that have experience in areas not covered by us," adds Onandia. PID compensates for this supposed lack of experience with its technological capacity. According to B., if company does not currently have a fairly robust design environment, it was not able to compete at this level.

In a nutshell...

- Business initiatives

Development of new products

- Challenges of negocio

Transition from a company whose main activity is manufacturing, also offer design services

Compete for contracts of high level

- Keys to success

Update 2D to NX

CAD/CAM integration

Check of interference in virtual Assembly

Teamcenter collaboration and functionality in the management of the engineering process

- Results

Ability to meet deadlines

Contracts with major international companies

The proposals expressed in contract

Fewer errors

Greater re-use of data

Upgrade to NX

Sapa originally performed their designs in 2D with Solidedge of Siemens PLM Software software. When they faced new challenges of design, the company decided to migrate to the system of digital product design NX, also from Siemens. The choice of PID was NX because the functionality was best suited to your needs, the CAM module was integrated with the design module perfectly, and this solution presented the best relation price-performance. In addition, the experience of the company with Solidedge, helped with migration to the new system.

B. said that thanks to the speed of working with NX, had been possible delivery of the projects within the deadlines. "Without a tool like NX, we would not be where we are." "Has allowed us to make really big contracts", says B.. "In recent years, we have concluded agreements with major international companies such as General Dynamics, the Rheinmetall group, the MAN Group, etc.".

CAD and CAM integration

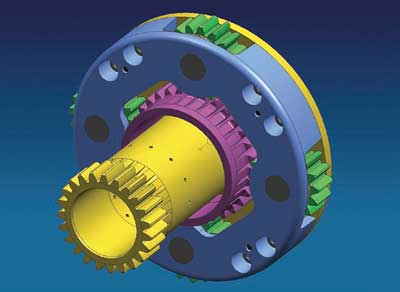

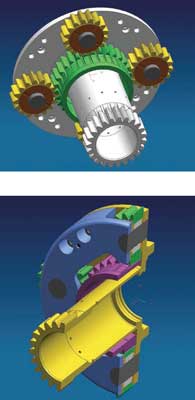

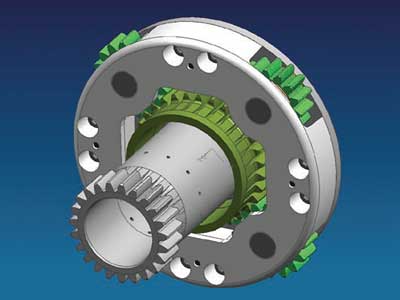

The margin of error between a product design and manufacturing must be minimal. To decrease the chances of bugs, PID submitted their product to a process that ensures the highest quality, from design to production. First, the Department of engineering, which includes knowledge of mechanics, fluids and electronic systems, made a conceptual 3D model of a product, taking into account the necessary parameters. In other words, it defines the product. Once completed this process, the design becomes the area of projection, the aim of which is the mass production of the design. The drafting Department is responsible for the generation of drawings and product documentation. Then the design passes to manufacture with all data processed by the above departments.

The characteristics that engineers PID noted in NX, underlined the fact the CAD/CAM integration.

He improved the cycle between design and manufacturing process. According to B., a long term goal is eliminate most of the documentation of manufacturing. "Our goal is to distribute our information at the level of engineering and projection and then distribute it directly to fabrication and measurement." "In so doing, we hope avoid intermediate errors this way," he added.

Teamcenter, the digital lifecycle management system, is another important aspect of the development environment by PID. Teamcenter has been used since the year 2005, in order to meet the needs of collaboration and manage the processes of the Engineering Department. Among the main features of the system indicates which allowed migration from Solidedge to NX, and the CAD/CAM/PDM integration allowed manage a form unified list of materials and finally, the Elimination of paper documentation.

Placencia r & d designs and manufactures auxiliary units of energy and transmission for heavy vehicles. The company is located in Andoain, Gipuzkoa.

Through the implementation of Teamcenter, PID has managed to reduce errors, reusing information, eliminate paper and duplicate records. This adds up to greater reliability reached by the change of working in 2D to 3D, which gives the company the ability to detect and eliminate potential interference between the parties prior to mount them. "Teamcenter allows us to have a robust structure of the product," explains Onandia.

Secure future

Despite the fact that PID is aware of the times ahead will not be easy, he believes that has required, both human and technological resources to deal with them safely. B. sure NX will respond with confidence to the future needs. "NX is a guarantee." "For example, we want reducing inertia in pieces to view the dynamic response of the transmission, determining centers of gravity and the masses." "NX is a very useful tool," says Onandia.

PID is confident that it will succeed in its goal of ceasing to be only manufacturers, to become one of the main producers of the market and that the use of technologies such as NX and Teamcenter will enable them to achieve this goal. "Our products are NX and Teamcenter Star", concludes the engineer of Placencia.