A single machine for the operations of milling and laser

on March 21, 2011

"For irregular surfaces and complex moulds 3D, textured laser is a solution that provides optimum results," thus summarizes Friedemann Lell, sales manager of Sauer Lasertec, the advantages of this innovative structuring technique. The user can benefit from various forms of the many years he has been working for the development. Friedemann Lell speaks well about the changing requirements of the industry: "In the automotive industry trend is to put aside the texture of leather and opt for new technical structures." "Manufacturers of PET bottles also expressing more complex requirements such as, for example, the integration of 3D logos". In both scenarios the textured laser is a clear advance of traditional engraving techniques.

Laser texturing is synonymous with greater freedom to the designers of products, and to remain low production costs. Many textures can not be produced using engraving techniques, or to apply the appropriate photochemical film there are cracks and, as a result, the steps in post-production are cumbersome and costly. The sales manager adds more advantages: "In the textured laser unused chemicals;" "the only tool for almost all metals is the head of the laser, so costs are kept low".

Any structural data that is required for processing by laser is created from bitmaps in grayscale. Then are they incorporated in digital 3D shapes using a 3D animation software. An example of this is the software solution called Maya that was developed for animated films. The LaserSoft3D software, developed by Sauer Lasertec, converts the structural data so that they can then be used in processing. It also positions the piece of work ensuring that the laser beam reaches its goal with a perfect angle of 90 °.

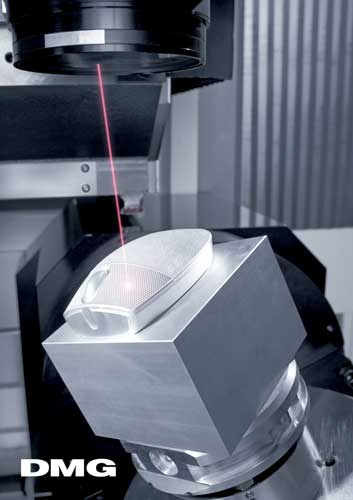

With regard to the requirements of the machine, Sauer Lasertec uses its extensive corporate know-how. Thanks to its 5-axis simultaneous processing capacity, the laser beam achieves its goals even in very complex surfaces and with his solid body monoBlock guarantee maximum positioning and repeatability. Is very important what comes next, Friedemann Lell explains: "with each passing, the laser removes only a few micrometers of material." "Depending on structural depth this can be 50 or more past".

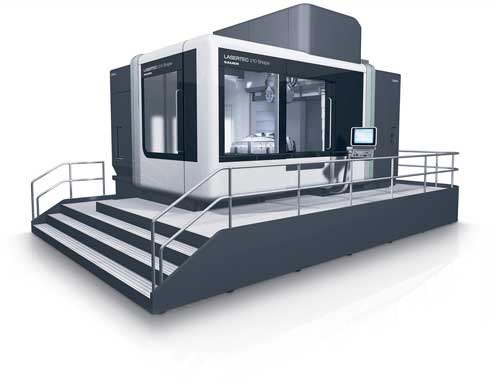

In their quest for technological integration, the Gildemeister group has also incorporated the textured laser in its DMU machining centers. The head of the laser is installed on the machine by means of an interface HSK (less than ten minutes are required to change it manually) and provides a texture to the mold of court with the same configuration. The new 160 DMU represents the beginning of the combined Court of milling and laser, while his older siblings, DMU 160, 210 DMU and DMU 340 models, round off the range of products. "These hybrid models are particularly suitable for customers who cannot be fully used a cutting machine laser, but who wish to provide a technology of milling and laser", thus defines Friedemann Lell the target group.

Laser structuring: supply chain

The first step is to generate structural data from bitmap in grayscale. Then, through a process of mapping creates a mesh flat and low distortion for the three-dimensional surface. This means that external 3D software (the same used for animated films) transferred the surface structure created earlier to the mapped 3D surface. LaserSoft3D programming system developed by Sauer will then calculate shoelaces laser so that the LaserSoft3D module can correct the position of the work piece and process surface.