Conductive plastic formulations with carbon nanofibers

February 9, 2011

Within the toy range available to the Spanish sector include the high variety of electrical and electronic toys: toys that incorporate electric motors or magnetic coils, electronic components, magnets or cabled, which represent around 20% of the productiongoing that percentage increased. The problem of electromagnetic interference is no stranger to these toy products, and that as any electronic device, they are sensitive to electromagnetic interference (EMI) which can cause performance issues. However, unless it be a toy of high price or complexity (such as a computer) currently is are failing to protect the toys of this type of electromagnetic radiation not desired, so it can have both a malfunction, or they can cause interference to surroundings.

With specified, Aiju is developing the project Emitoy, funded by the Impiva and dossier IMIDIC/2010/40, whose main objective is to obtain new conductive plastic formulations to prevent these interferences of electromagnetic nature. To this end, proposes the incorporation of nanofibers of carbon to the thermoplastics commonly used in the sector toy (PP) to levels both electrostatic dissipation, electrostatic painted as electromagnetic shielding. The main features that must meet the materials obtained are: that are light (plastic material base), comprehensive response to magnetic field and electric field, price competitive and actionable by extrusion, injection.

Materials

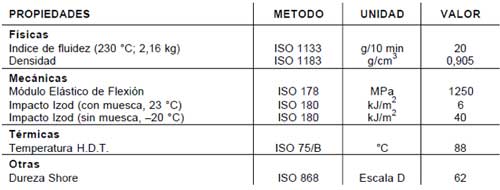

Has been used as a matrix of compounds (PB 180 G2M) polypropylene. Some of the properties of the material are included in table 1.

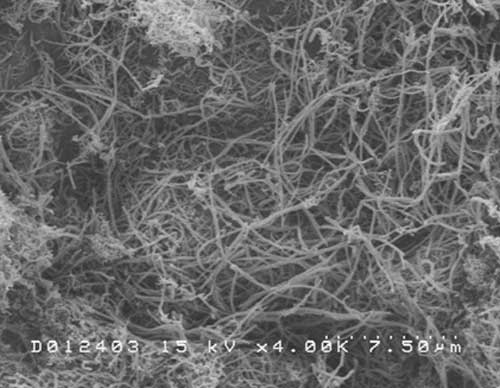

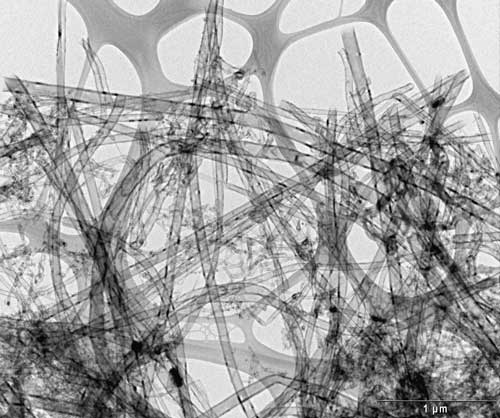

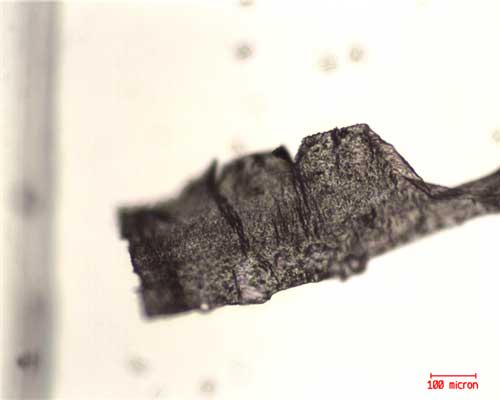

The nanofiber from carbon Ganf, employees have been provided by the Spanish company Grupo Antolín Ingeniería. They are included in Figure 1 shows images for microscopy Sem (left) and Tem (right), showing that there are very long (several microns), entangled with each other and with a mean diameter of 60 nm.

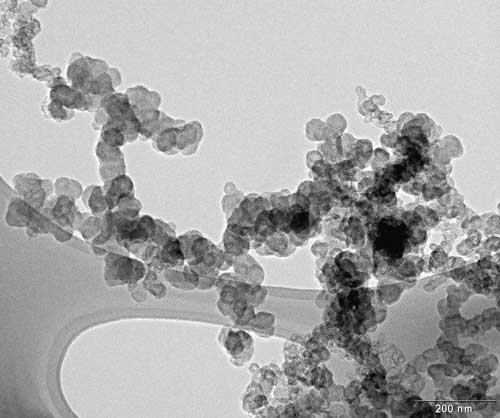

The used carbon black has been the company Timcal Ensaco 250 G. Images Tem (Figure 2) shows that it is formed by spherical structures of approximately 20 nm.

Experimental methods

Preparation of formulations

The mixtures were a mixer of HaakePolylab QC laboratory with roller bambry, of 50 ml. For the realization of the nanocomposites, added masses of matrix and nanocarga for the final achievement of 50 ml, whereas the densities of Ganf, CB and PP values 1700, 2100 and 900 kg/m3, respectively. We used a temperature of 220 ° C, a speed of 60 rpm spindles and a mixture of 40 minutes time. After mixing, were prepared in the press of hot plates 1 mm thick films at 220 ° C.

Analysis of the dispersion

For the analysis of the dispersion, micrótomos, in cryogenic conditions, 15 microns of thickness with a LEICA team were severed. THE PP has a temperature below glass transition point, so it is necessary to carry out this operation when it is in liquid nitrogen. The microtomos were observed in an optical microscope Nikon transmission to 100 increases, and the images were designed for a specific software.

Results

Nanocomposites Ganf-PP

Figure 3 shows the dispersion in micrótomos of Nanocomposites to 2.5% in weight of Ganf. You can see that the few agglomerates seen are smaller than 5 microns. Therefore, the dispersion by dispersion (conditions of the mixer) procedure are very satisfactory.

Nanocomposites CB-PP

Figure 4 shows an image of optical microscopy of transmission of black carbon Nanocomposites with PP with a concentration of 2.5%. The dispersion obtained after processing is good because agglomerates are not observed.

Conclusions

The results show that mixtures obtained with black smoke and carbon nanofibers have good dispersion in the matrix. The high rate of flow of the PP facilitate favors the dispersion of the load.

Given that the objective of the project is the development of hybrid Nanocomposites of polypropylene with nanofibers of black smoke with electromagnetic shielding and carbon, the next tasks will include incorporating carbon black to the array of PP by a double corrotante screw extruder, and then different amounts of Ganf are adicionarán: 2, 4 and 6 per cent.

Thanks

This project is funded by the Impiva (IMIDIC/2010/40). We also thank the Department of chemical engineering at the University of Alicante for the advice received.