Nanomoldeo, high precision and micromoldeo for injection moulding

December 2, 2010

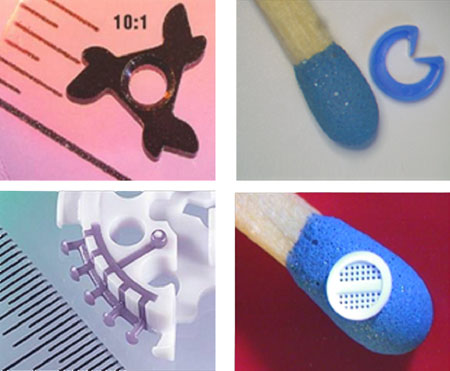

Specialized production micropiezas of high-precision can refer to different fields with great acceptance: medical pharmaceutical, orthodontics, watchmaking, electronics and any industrial division you need parts, for example, with significantly lower a gram, but of extreme precision weights.

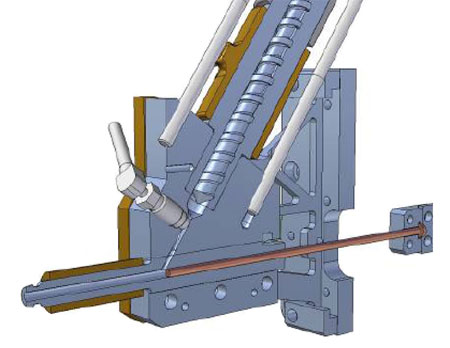

Machines suitable for this type of microinjection must have the latest technologies of the sector, electrical servo drives and special groups of injection. "The injection of the MicroPower unit can be considered the latest innovation in Microsystems technology", says the company. It is capable of injecting a thermally homogeneous mass with minimum lengths of thread. In addition, the injection module allows processing of all materials suitable for molding by injection to a volume of 3 cubic centimeters and feed all sizes of standard granulated.

For micro- and nanopiezas

On the one hand, dynamic plunger injection unit ensures that it is possible to apply even the maximum pressure in the cavity with absolute repeatability. On the other hand, the injection module has been designed to minimize both the basis of the casting and the trough.

Thanks to this technology, it creates a great margin of processing, which helps to stabilize processes quickly. Accordingly, it is not only possible micropiezas, but also "the most tiny nanopiezas, in a repeatable process and within a minimum time".

MicroPower is available in two models, fully electric drive of the series, with a clamping force of 5 and 15 tons, which are provided for a considerably broader scope. A unit of injection of last generation, with a volume of injection of 1 or 3 cm can be used in each of the machines. The field of application of the machine is not restricted to micropiezas, thanks to the increase in the strength of closing and the volume of injection, the machine can also produce pieces of big production or work with moulds with the largest number of cavities.

The standard model of the MicroPower serves as a basis for a molding machine injection fully electric, "very accurate and extremely fast". The castings can simply fall through the trapdoor of output or be drawn by a team of manipulation. Ample free space around the unit locking allows even the placement of larger claws.

The machine has been designed to incorporate subsequent processing steps, or possible systems connecting modules with different functions. This includes, for example, the monitoring of the fully automated quality control or the packaging parts, either individually or in batches. Even complex pieces, such as parts molded with inserts can be manufactured or pieces of various components, safely and at low cost.

Control to the machine and peripheral equipment

Wittmann Battenfeld has adapted its range of peripheral equipment for the production of nano and micropiezas, with dehumidifiers, feeders dryers material of low-volume and low flow and equipment of heating with tailored performance specifications. As regards automation, the company has developed the Scara W8VS2, a special for small parts vertical robot powered by three servo motors, able to extract and then process micropiezas with great dynamics and accuracy. In this case also has focused special attention to complex tasks as molding with technology.

The control system of high-performance Unilog B6, which facilitates the operation of moulding machines injection, along with all the integrated peripheral equipment, are now available also for the number of fully electric machines, from the smallest model to the largest. The operation and control of the injection molding and integrated peripheral equipment machine can learn quickly and intuitively.