Siemens PLM Software redefines CAD/CAM/CAE for the NX7 productivity

September 16, 2010

NX7 also, together with Teamcenter - product lifecycle management software - the first solution compatible with the new PLM technology of high definition (HD-PLM).

"Our new HD-PLM technology platform provides a visually intuitive environment in NX which improves the decision-making on the product development process and creates a really significant value for our customers and the industry itself," Joan Hirsch, Vice President of Siemens PLM Software product design solutions. "The value of this new version not only lies in the power of each of its many improvements, but also new features incroporadas in the modules of product design, analysis and manufacture of components that can increase productivity by up to 80%."

Decision-making of product development in high definition

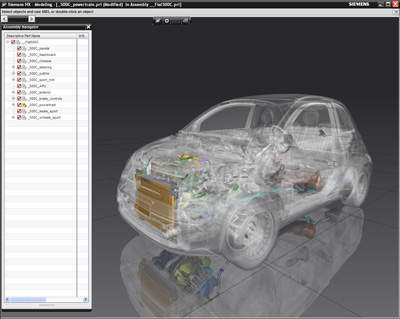

With the release of the 3D environment of high definition (HD3D) announced last year and improved in this latest version of NX, Siemens PLM Software begins to realize his vision of integrating HD-PLM technology into their enterprise solutions. HD3D combines the power of NX and Teamcenter under the HD-PLM environment to view and provide all the information necessary to understand, collaborate and make decisions in a global product development environment intuitively.

HD3D provides the four foundations of HD-PLM, with a resolution of support to the decision-making and analysis to customize the user experience, placing it in the appropriate context, proactive assistance to the collaborative decision-making through the management of tasksIt clarifies the user experience to present information in an intuitive manner and validates their decisions against rational processes. HD3D offers an effective alternative to navigation and processing of lists of data attributes and its manual correlation in 3D product models. Also allows users visualize data PLM in an interactive manner and with the level of detail is necessary. Through the visualization of 3D products, users can easily put in the proper context and respond instantly to any question on the status of the project, design changes responsibilities of each team, incidents, problems, costs, suppliers and any other attribute. The color coding, labelling on screen and descriptions allow faster visual advice and interpretation of all the details relating to the product development and decision criteria.

HD3D also works with NX validation tools, providing direct visual interaction that accelerates validation of product designs in relation to the requirements. Rich visual information allows the user to monitor critical functional requirements during the development process, and allowing a quick takes decisions with a high level of confidence to ensure and maximize the quality of the product.

"Siemens PLM Software has reached a new milestone with this version and expands the HD-PLM concept with its HD3D integration in its wide range of products," says the Dean, editor in Chief and co-founder of DEVELOP3D magazine. "The possibility of using NX and Teamcenter to visualize data, often buried in a database in a graphical way and in their proper context, enables rapid detection of a wide variety of incidents and potential 'bottlenecks' relating to the development of a product." This allows each of the members of the team involved in the process properly documented decisions, with a high level of confidence and greater efficiency. "This provides a high productivity of our customers".

Redefining productivity in product design

In addition to support for HD-PLM, NX7 incorporates numerous new features and improvements to redefine the concept of productivity in product design. NX7 improvements in its integrated CAD applications include tools for rapid design such as the creation of vector sketches, the extension Synchronous Technology to transform the free modeling, and the new DraftingPlus tools that significantly improve the design in 2D.

- New rapid design tools speed up the creation and positioning of profiles 2D, automatically calculating the restrictions and the design intent. As a result the time spent to create new models from scratch is reduced by more than 50%.

- The integration of innovative Synchronous Technology with NX-free modeling dramatically improves the process of shaping, making it easy to work with any geometry, including imported models. The user can start from a Prism or analytical geometry and use advanced modeling tools to create complex organic models in much less time.

- The additional capabilities of Synchronous Technology offer improvements to the functions of textures, Assembly, geometry of planes, mergers, bevelling and vector methods for reuse of geometry.

- NX DraftingPlus is a new set of design tools that enhance the 2D of NX functionality and integration with 3D models. An interface based on each user's role allows to contextualize the work of 2D design and offers powerful features such as tools of creation and modification of curves with the possibility of generating geometric shapes from 3D curves 3D, and the Elimination of intermediate steps in product design. NX DraftingPlus allows a complete integration of 2D and 3D workflows, eliminating any need to use an additional 2D CAD.

Redefining the productivity of product analysis and simulation

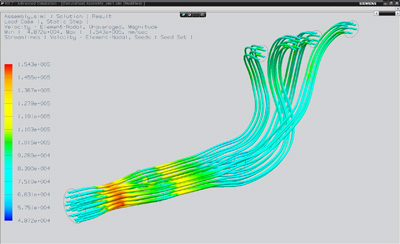

The NX of design and analysis environment has demonstrated its ability to drastically reduce the time needed engineers to validate the performance of the product as your design evolves. The latest version of NX incorporates the largest number of improvements that ever done in their functionality falls. These enhancements redefine productivity of CAE to improve their integration with product design, increasing NX CAE leadership in multifísicas solutions, and providing new forms of contrast digital simulation with proven data models. As a result, engineers can make better decisions in less time to create better products.

- The integrated design and productivity in falls have been improved in NX7 thanks to a new model of development of workflow to assist users when working with complex geometries as meshes of fine panelsbeams, screws and much more. Many of the improvements channel the flow of data between design and analysis, including significant improvements in the analysis of flows of composite laminates. Thanks to its intuitive approach to modeling or Assembly of finite elements, NX simplifies the way in which analysts work with complex models and allows engineers to work with models of systems that are updated when increasing the fidelity of the design.

- NX CAE increases his already incredible integration with a wide range of detection technologies and solution of problems by adding new multifísicas and integrated solutions that include durability and analysis of movement with flexible objects, as well as more solutions for structural analysisthermal and flow. The flexibility to analyze parts of a mechanism is important, because it can affect the geometry and cause serious incidences of design. With NX7, engineers can validate designs using more reliable models that combine elastic and rigid deformation moving to evaluate the effect of the flexibility of each component on the performance and durability of the mechanism.

- NX 7 introduces two new products falls: NX Finite Element (FE) Model Correlation and NX FE Model Updating. This new offering represents a system aimed at the analysis with an intuitive user interface that has been created to adapt to the needs of the analyst falls. The products provide a comprehensive, integrated system for the analysis of incidents, planning pretest, correlation test-analysis and updating of models.

"When the results of the analysis required changes in the design, we can apply these changes efficiently using Synchronous Technology" says Jerry Baffa, project engineer for the Department of investigation of the shipping company Damen Shipyards. "Modify the mesh does not take effort and allows you to very short design cycle".

Redefining the productivity in the manufacture of components

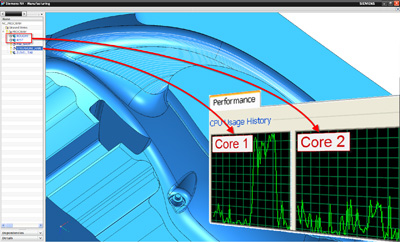

The combination of CAM and CMM in NX capabilities is one of software solutions for the production of more sophisticated components of the market. NX7 redefines productivity in the manufacture of parts with the addition of two new applications that place the user in the context of a specific task, largely by reducing the time required to schedule components of turbo-machinery, and maximizing the effectiveness of the programming machines of coordinated measurement (CMM) offline.

- NX Turbomachinery Milling accelerates the process of NC programming for rotating components complex of five axes and various blades. This integrated application NX CAM for rotors and driving machinery offers a range of automated functions and in a specific environment that much simplify the task of creating the processes required for these complex mechanisms. The new functionality is supported in a large number of functions already exist in NX CAM, as the simulation of machinery based directly on data post-processing to help validate the decisions in NC programming. NX Turbomachinery Milling can help produce better results in half the time that the software of corrugated regular.

- NX CMM Inspection Programming works in the context of a solid 3D model that includes coordinated measurement mechanism and its parts. Totally automated, the inspection data and routes of polled are generated automatically from the PMI data attached to the 3D model and direct. This entails potential reductions of up to 80% at the time of inspection. This integrated application is completed with a simulation of collisions which helps validate decisions of CMM programming and significantly improves the effectiveness of programming.

"NX Turbomachinery Milling offers a very significant productive advantage for the NC programmer specific design for programming of rotors and propulsion machinery". "At the same time, the highly automated functionality NX CMM makes that inspection programmes form an integral part of the PLM processes," says Charles Clarke, renowned Advisor in CAD/CAM and writer. "This latest version of NX amounts to Siemens PLM Software to a new level of productivity in the manufacture of components".