battenfeld-cincinnati: Hall 16, stand B19

For the first time since its merger, battenfeld-cincinnati in the K

In April this year the two companies operating under the same roof but independently, Battenfeld Extrusionstechnik GmbH, Bad Oeynhausen and Cincinnati Extrusion GmbH, Vienna, gave to know your Union to create the largest global brand for the manufacture of pipe extrusion linesprofiles, plates and films. Senior management for battenfeld-cincinnati developed a new organizational structure based on three divisions: construction (profiles), infrastructure (pipes) and packaging and packaging. He was convinced that "through our orientation towards the final product we can ensure our long-term success, and we can win market shares". "Through the new organization, in each of the three divisions is concentrated our know-how optimally, which for us is a technological advantage and for our clients, saving money."

"Our new direction occurs just at the right time." "Extrusion market is in a phase of promotion and interest in innovative machine concepts has come again" confirms Arnold. From the lowest point reached in 2009, battenfeld-cincinnati has once again recorded a clear increase in order intake, as a result of an upward trend. Previously, like the majority of manufacturers of machines from 2007 to 2009, the companies Battenfeld and Cincinnati had to deal with a fall in turnover of approximately 50%, before which both companies reacted soon with the adjustment of the template and putting up regulation of employment measures. Today, battenfeld-cincinnati has 700 employees worldwide. Its plants in Bad Oeynhausen, Vienna, Kempen, McPherson and Shunde are well prepared to respond and serve adequately to the increasing demand for machines that offer reductions in energy consumption and higher performance, as well as growing international marketsthat they are currently in the Middle East, Asia and Africa.

The most outstanding machines of three divisions:

Construction

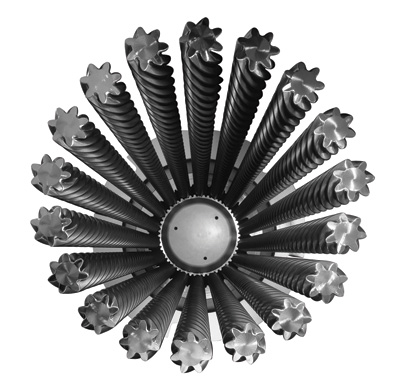

The construction, directed by Rainer Kottmeier, Division will present a new series of extrusion machines of dual parallel spindle. Thanks to a joint know-how, designers have been able to develop a new generation of extrusion machines optimized mainly for the processing of PVC, which offers a significantly improved performance and many other benefits. Four models, with spindles of 78 to 135 mm in diameter and a length of 34D processing unit, cover a range of performance in the manufacturing of profiles of 100 to 1,000 kg/h. Primary responsibility for the rise in the yield of about 25 per cent as compared with the versions of previous machines is the prolonged unit of processing, the incorporation of the currently most powerful wheels of four trees that exists. In addition, these extrusion double spindle machines convince by for the restraint of the core of the spindle maintenance-free and self-regulating, basic geometries of the spindles installed universally, isolated elements of the cylinder, as well as special equipment anti-corrosion processing unit.

In addition to manufacturers of profiles, the construction Division also supports all the customers who want to manufacture plates, as well as applications in the field of the dais, fences, railings and the WPC.

In the K this Division will report on their most recent development for a market on the rise as the WPC, even during the crisis presented by stable growth figures. battenfeld-cincinnati shows his new extruder conical fiberexK72, ideal for those who are beginning in this sector.

Infrastructure

The infrastructure Division is responsible, under the direction of Walter Häder, of all the solutions at the global level on the theme of tube extrusion. The infrastructure Division offers in numerous K answers the growing demand for concepts that save energy. Under the name Green Pipe, battenfeld-cincinnati encompasses the entire concept for the extrusion of pipes with low energy consumption, which consists of three different possibilities and a notable reduction in the length of the area of cooling and energy costs. Systems Efficient Air Cooling (EAC) and KryoSys, as well as the new concept of equipment of secondary treatments that occurs for the first time in the K belong to this section. The EAC system is responsible for achieving an effective cooling of the tube extruded with an area of cooling between 25 and 30% shorter, due to the exchange of air in the interior of the row of the tube. And a cooling of the mass melted in the row that allows the reduction of 20% more in the area of cooling is achieved with the addition of special head with spiral mandrel distributor KryoS.

In addition to the reduction of the length of the area of cooling and the chances of recovery of energy, both concepts ensure a way of working carefully with energy resources. The Green Pipe system is complemented by a secondary treatment equipment presented for the first time at the K, whose zone of cooling reduces virtually halved power consumption and requiring much less flow of water for cooling.

Containers and packaging

Along the lines of extrusion for the manufacture of films, the Group of products for grain also belongs to the third group of products of battenfeld-cincinnati. The Division packaging and packaging is headed by Henning Stieglitz. This Division introduced the k a complete series of extrusion machines for direct extrusion economic and flexible PET films.

Following the submission of the first extruder of this series - model 1-120-34 D/V single with modified planetary roller - three years ago at the K fair, this manufacturer of machines now accompanies this growing market of PET films with a full set of machines. In total there are three models covering the middle range of yields, between 600 and 1,200 kg/h. The decisive advantage in this series of machines is the ability to process preacondicionado PET, thereby saving energy costs. At the same time these extrusion machines convince by their compact and robust construction and low maintenance required, so that the investment costs are recovered quickly. Very low cost of the life cycle of the new series of extrusion machines are the answer to the demands of the transformers, seeking economic concepts of machines.