'Innovation to the Charter' in the 'lounge' Ferromatik k 2010

September 13, 2010

In total, there are three machines in the k menu

Menu 1 - pure Packaging served in the new 160 F

The F series is the result of a comprehensive research and development in Ferromatik Milacron. Starting in 2011, the F series will be gradually replacing the existing series of the firm, including the fully electric machines Elektra, hydraulic families K-Tec and the hybrid machines, Vitesse. Once completed the launch of the product, the F series will be available with ten forces closing from 50 to 650 tons, directed to the sectors of the packaging and packaging, consumer goods and medical technology. "The new F series leads us to our roots, allowing us to concentrate on our main strengths," said Gerold Schley, general director of Ferromatik Milacron. "In the 1970s and 1980s had a F series, which still enjoys an excellent reputation today", added. The name expresses the commitment of the company towards a series of machines only to forces of standard closing with a clear focus on specific industries. The F also responds to Ferromatik.

The versatility of the philosophy of the F series allows you to easily combine individual modules, so that each machine is fully made to measure. Depending on the requirements and priorities of the inyectador, the configurations of the machine can emphasize areas such as performance, consumption of energy, dynamics and precision.

The inyectadores also have the possibility to choose electric or hydraulic, drives and can choose and mix components for each axis of the machine. In this way, the transformer ensures maximum efficiency of the machine for each production work.

Each machine of the F series is:

• Economic - reduces energy and produces more

• Easy to use - Mosaic controls guiding the operator

• Practices - easily accessible and low-maintenance

• Custom - easy to customize for the work of a production of the real world

• High value - production quality, quiet operation and high repeatability

• Trust - service of experts from the first moment

• The latest technology - consist of the latest technological developments.

Thanks to the flexible machine design, upgrades and retrofits of existing machinery are implemented easily, providing customers a continuous adaptation according to requirements.

Even the first impression of the series F is striking. The base color is white, referring to its clean operation. A horizontal gray line around the machine emphasizes, and visually connects the main areas of operation. The familiar red tone of Ferrromatik occurs in two thick flashes of color in the units of closing and injection, expressing the speed of the machine, the power and dynamism.

At the fair, the company presents a 160 F with a 160 tons clamping force and a unit of universal injection of 50 with a diameter of the spindle of 50 mm. The 160 F will demonstrate the production of packaging of polypropylene in a cast of two cavities of the manufacturer of molds Italian Incos, in a cycle of six seconds.

And the machine is not the only novel. The robot FMR 8-5 Advanced of Ferromatik Milacron, will pick up and deposit parts, also debut at the fair. Manufactured by the Swedish manufacturer Wemo, the controls for the robot are fully integrated with the Mosaic machine controls. The new robot is available in six sizes, each of them in basic or advanced version. "The solution integrated with our veteran partner Wemo demonstrates our commitment of providing systems and simple solutions", noted Thorsten Thümen, director of product development at Ferromatik Milacron.

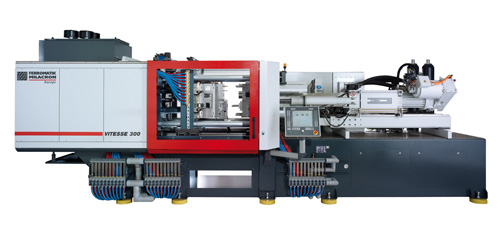

Menu 2 - Tapas with printed labels served in the 300 Vitesse

The high performance of Vitesse series was introduced for the first time in 2009. The French word Vitesse expresses exactly what means this machine: speed. It is available in four sizes: 100, 300, 400 and 500 tonnes. The original selection of sizes (1,000, 1,650, 2,650 and 4.400) injection units has expanded due to the demands of the users of larger sizes. Now, Vitesse also offers to the market with sizes of 6.610-10.100 international injection units, which means that they can be purchased with a total of 13 configurations.

At the K 2010, will present a 300 Vitesse with a complete production unit, including labelling in mold, quality control, stacking of pieces and package. The manufacturing cell has been created jointly with the Swiss partner Müller IML. The model 300 t Vitesse will be presented with a unit of injection of 2,650 and will demonstrate the production of a labeled rectangular cover in a 4 + 4 stack mold cavity and a cycle of five seconds. But there's a surprise inside: four labels of propylene from the Belgian company Verstraete will occur on a line of partition in the mold of stacking.

In the second line of partition, it will produce four tops with labels of role of Engelhardt. After removing parts, lids are transported to a tape of transport where they undergo a quality control.

Finally, the lids are stacked and packaged in boxes, each with 1,216 tapas. Every hour, every one of those boxes are packed and are ready for shipment.

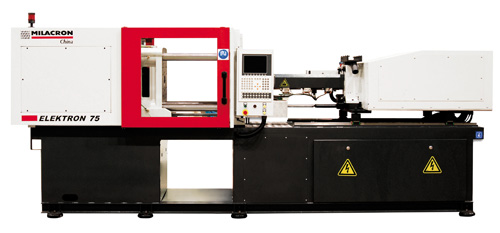

Menu 3 - boxes for business cards served in a 75 Elektron

The Elektron is the result of the synergy between the Milacron companies around the world. The machine is based on technologies used in the proven series Elektra from Ferromatik Milacron in Malterdingen. Subsidiary india contributed to the new machine engineering and Assembly of the Elektron has been developed in Milacron China.

The Elektron is available as an economic model. It is available with forces of closure from 50 to 330 tons, with a selection of seven units of injection from the international sizes 55 to 1540. A total of 23 combinations, are possible each with three sizes of diameter of spindle option.

In the K, the signature will show a 75 Elektron, with a clamping force of 75 tons and a unit of injection of international size of 300, which will manufacture boxes of cards in a cycle of twelve seconds. The mold of a cavity and the technology of hot channel is SMD. Special attention deserves the ejection Quick Strip. With this technology, the ejection of the piece occurs automatically with the opening of the mold, without using the ejector of the machine.