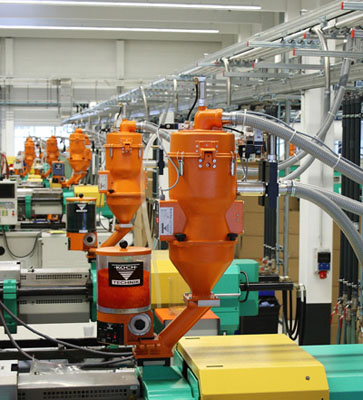

Koch-Technik is presented at the fair 2010 K as a complete supplier of peripheral devices

September 10, 2010

As a novelty in the sector of dosing, with the Exako will be presented for the first time to the international public a gravimetric direct dosing device for use in injectors. This system guarantees the absolute accurate dosing in smaller quantities, independently of external influences. The exact dosing by volume of camera is here combined with a Gravimetric dosing system. Thus, the minimum amounts of 1 to 55 grams can be added to a main component.

The Exako is equipped with a balance that records the actual weight and compare the value to the nominal value calculated by the control developed recently by Koch. Thanks to its volume of camera closed in itself, with an accuracy to +/-3 grains can be dosed 1,000 grains. The newly developed control apparatus is based on a Siemens SPS S 7 command component. Menu guide is carried out by means of a touch panel. Also, it can be carried out without too much effort saving recipes and all the other values as well as the documentation of the dosing process. As in all other devices, the Exako also can be integrated without problems in the system of standardized units Koch.

Comko, a compressed air dryer

In addition to the broad spectrum of drying systems include a second novelty Koch - Technik presents at the K fair. The Comko is a compressed air dryer and therefore a slightly different drying system. The Comko is designed for direct use on the machine of machining. It is particularly suited for the drying of small quantities of hygroscopic materials. Its drying capacity is up to seven kilograms per hour. The heat power is only 0.5 kilowatts. In the Comko, which is supplied with a volume of 6, 12 and 20 litres, the gate valve and the preparation for the Koch conveyors are series.

Also at the fair company will present the dry air of the Eko series dryers, devices of drying that according to the temperature of the material to be dried can achieve power savings of up to 20%. Combined with the control of installations Eco developed and patented by Werner Koch, the potential savings can reach up to 40%. In the dryer Eko find proven and matured technique of the number of dryers CKT Koch-Technik. Thermal damage due to too long drying times are excluded due to fully automatic control in all the materials, but especially in the sensitive thermally as PA, PC, LCP or POM.

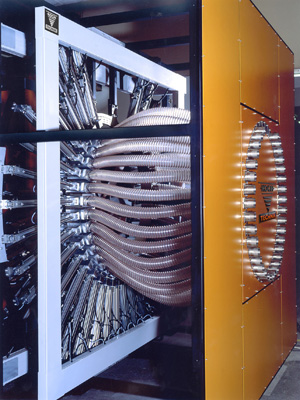

Also, the compact dry air dryers in the series KKT for low dimensional spaces offer up to 40% of potential savings in energy costs. The portable auxiliary dryers are designed for a number of dry air of 55, 75 and 100 cubic metres per hour depending on the model. These have a Koch-Technik Switch control, thanks to which the enormous potential of saving is achieved. A microprocessor specially developed for these devices control guides the user through the program.

The company is also well established in the sector of direct coloration of the Kem series devices, which are supplied for different amounts of dosage from 0.5 to 200 kg per hour. The Kem series, which can be used in machines for moulding by injection or extrusionadoras, ensures the user shades of color in the final product are exactly equal. This is guaranteed by the direct dosing of the masterbatch in the area of insertion of the worm. The coloration is carried out through the camera volumetric dosing. In the event that changes the values of dosage, this reflected immediately in the process. If you change the product, there is no material mixed in the machine. Control is integrated into the device and you can save different recipes after dosing. Series offered KEM with dosing roller for pesos per stroke of 2 to 10 grams.

Accurate according to the recipe and reproducible dosing at all times allow the Graviko series, represented at the fair with three pieces of exhibition. Patented and Gravimetric dosing and mixing system adds small amounts up to 0,3 grams of accurate and reliable way with the maximum precision of repetition. The individual components (grain, dust, material for grinding and fine gravel) are ground in a tank weighing. A balance is responsible for determining the actual weight and transfers it to the control of Koch, where you compare the value to default nominal weight. The oscillations are compensated fully automatically. In this way, is not exceeded value so far, in a metered addition of 1,000 grains with a tolerance of just +/-3 grains. The Graviko is equipped with a newly developed command of the MCm-G Touch type apparatus. The Graviko series can process 3-2,000 kg/h of material depending on the type.

In respect of the distribution of material, the company shows its patented material of the Navigator type transportation system at the K fair. The central distributor system is a real alternative to the transposition of manual control station. With the Navigator. they can be distributed automatically and with time saving up to 40 different plastic materials in up to 40 machines for machining. In addition, it is designed so that the distribution of material is carried out without waste. Potential impurities or mixtures are excluded.

All Koch-Technik products can be used flexibly, are very well adapted, and can thus be integrated without problems as individual modules in the system of standardized units Koch. All components of the system of standardized units can be combined with each other, have flexibly and expanded. Koch-Technik system allows customized solutions in this way for mixing, transporting and dosage of plastic granules. The modules of the system of standardized units Koch are designed and adapted in such a way that they can be combined with only a few maneuvers. This saves time and therefore unnecessary costs.