Manufacturing of prototypes of high accuracy and detail

March 16, 2010

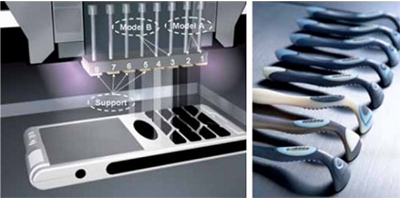

Using the technology of light curing by ultraviolet light, the pieces are built with two different fotopolimerizables materials: model material and material support. Acrylic resins, are used to obtain the model parts while necessary during the process of construction of the pieces are made of a hydrosoluble jelly which, once completed the manufacturing process it is removed with a simple stream of water.

This technology allows to manufacture parts with high dimensional accuracy (0.1 mm - 0.2 mm depending on the geometry, orientation of the piece and print mode), fine detail and smooth surfaces. It is possible to make walls up to 0.6 mm.

Measures maximum of parts that can be processed in the equipment available in Aiju (Objet Connex 350) are: 350 x 330 x 200 mm. The General characteristics of the materials available include an 83 Shore D hardness and elasticity of 2400-2700 module MPa for the more rigid (Fullcure 720, 830 and 840) and 61 to 75 Shore A to the flexible (TangoBlack and White)which simulate the behavior of the silicone or rubber. All of them allow the reproduction of details and textures.

With the advent of the new machines Connex Matrix, is marked a revolution in this type of technology is the only one capable of manufacturing with two different materials and even generate digital materials such as composition of the two materials base so that the Repertoire of end to obtain materials is even greater.

The transfer of the 3D geometry of the solid model to play with rapid manufacturing systems is done via STL files. A STL (standard triangulation language) file is an approximation, using polyhedral meshes, geometry of a 3D surface. The STL format has become the standard format of transmission of data for Rapid Manufacturing industry and the majority of the current CAD systems are capable of producing files in that format.

STL files are processed by specific machines of RM software and 3D geometry is converted into a number of 2D sections, which will be subsequently reproduced with different processes, materials and technologies.

The prototypes of high-quality printers Objet 3D in several materials open us an enormous range of application possibilities.

As any prototype, they can be used to initiate marketing campaigns without having to wait for the first batch of production. They are also an excellent tool to enhance design and facilitate its approval prior to the manufacture of the mould.

Excellent finishing surface of Objet 3D printer allows the realization of vacuum masters for casting moulds, mould wax injection to employ techniques of wax and females of electrodes of precision and detail (even textured) for baths electrolytic (galvanized copper) which is the most economical method for runs short.

The materials can manipulate and polished easily. Thanks to the multiple range of digital material properties that can generate the Polyjet Matrix technology, to create, for example, a rigid object with flexible buttons, all on the same piece, without seams or cracks.

The General characteristics of the prototypes manufactured by Polyjet allow:

• 16 Micron layers: excellent surface finish.

• Spectacular resolution of 600 x 600 x 1600 dpi.

• Wall thickness of 0.6 mm, with any geometry.

• Precision between 0, 1-0, 3 mm very interesting with respect to the original CAD design.

• Variety of materials with different properties and colours.

• Allow assemblies and clipajes.

• They allow various levels of flexibility due to the digital materials.

• Surface finish without marks in curves.

• Does not require a time of healing.

• Machinable, pintables, galvanizables, etc.

Volatilizables • for patterns of sacrifice.

Also, object technology has entered the personalization market through specific machines for the manufacture of hearing aids, even their Objet acrylic resins are accredited for medicine. One of the clearer areas of application is the manufacture of surgical splints employed in the non-invasive techniques of dental prosthetic surgery.

For this work has splintered from the basis of previous experience of research personnel in other technologies 'imprecise' such as the technology of ' Selective laser Sintering'.

This technology works with a laser that 'draws' layer to layer, so that there is one standard deviation by the own displacement of the laser and the interpretation or its projection to reach Tween layer. This technology requires a system of recalibration or readjustment of the laser that is gradually desenfocando, which leads to deviations on the original design. These deviations are rectified using factors of scale on the piece to be manufactured in the X axis and and and a few factors of Offset on the laser in the axis X and and.

By reference to this way of working, we propose a way to 'calibrate' the Polyjet manufacturing system in such a way that we improve the obtained values.

The scale used in SLS is very big and reflects differences in huge values, in our case we raise a level of smaller size in reference to the size of piece that is usually produced using this technology.

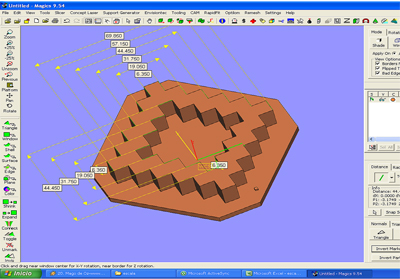

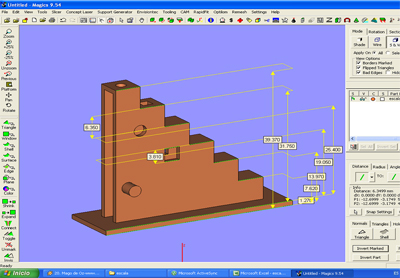

Elevations shown in image 1 are extensible to the four positions of the scale, left, right, up and down, so that we get six steps up external and six measures internal to down five internal measures up and five internal steps down. Idem for the left and right, which leads us to get twenty-two different measures by axis (ten internal and twelve external measurements).

For the Z axis, although we consider that the layer thickness is 16 microns, is excellent (compared with SLS thickness of case in the best of 70 microns) but also we carry out a scale.

This Z scale gives us information through nine benchmarks, which gives sufficient information on the scaling that is needed.

Once designed and planned the method of calculation, are produced by light curing (Polyjet) scales, in our case using machinery Objet Connex 350 (bimaterial), available on the premises of Aiju.

Later through the system for calculating quadratic errors using an Excel sheet developed for this purpose, we will take different measures to compare, and they are directly on the Excel application.

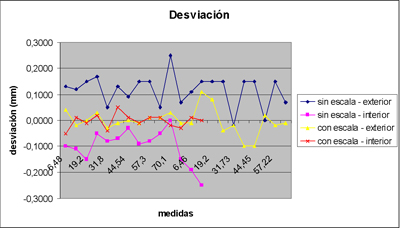

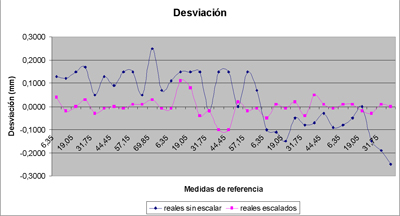

The figure 1 show the deviations of the Objet piece with respect to measures basis. Taking as reference the measures taken in the interior and the measures taken abroad to compare precision.

The graph shows in blue the action on the part scale with standard of Polyjet manufacture, while pink measures show the deviations from the piece made with the retrieved scale factor.

As you can see in the comparative images, in the previous study, an average deviation of 0,1 mm although there are nominal values above 0.2 mm allows us to conclude that the accuracy of the manufactured piece is very high and therefore faithfully reflected the designed CAD. The average value of deviation is 0,0325 mm.

If we look at the line of trends of the actual measures on the scaling retrieved prototype, all values are below 0.04 mm, in the worst cases in 0.1 mm, but as a value half 0,0025 mm, i.e.a precision 10 times higher than the value calculated initially and without scales. Therefore we can say that the Polyjet technology is a technology of rapid manufacturing very precise that optimized you can achieve very good accuracy values.

Although we have examined different scaled technology Objet, the proposed calculation model of scaling is very complex, at our discretion, the scaling factor right is as important or more the CAD model to compare their different heights and its different dimensions than the method of calculation of the scale factor, in the event of different levels, in different positions in manufacturing and taking into account the type of reference (internal or external) make that the retrieved value takes into account all the possibilities of cota.

Therefore, the scaling factor obtained is more generic and representative of any value to be manufactured using this technology.

It has been shown that, in a technology as accurate as it is Polyjet (accurate compared with the rest of rapid prototyping manufacturing systems), although the manufacturer tell us that it is not necessary to scale parts to improve its accuracy for that is optimalreally if that get great results by applying a system of scaled up correct and a calculation of appropriate scale factor.

Including Rapid Tooling in practical applications

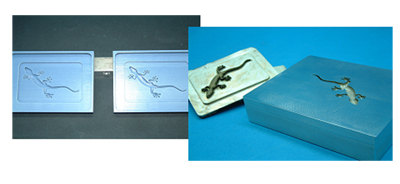

One of the most innovative applications that can be given to this technology and that significantly accelerate the process of manufacturing is the Polyjet technology for the manufacture of the negative, in the process of electroconformado for the manufacture of electrodes.

Supported in the phase of electroconformado with the Centre for integrated manufacturing of the University of Las Palmas de Gran Canaria, which have developed a very innovative system that solves the problem of the uniformity of thickness on the shells of metal electrodepositadothey have dealt with it through the use of auxiliary elements, such as auxiliary anodes and insulating screens, cathodes of sacrifice, simultaneous cathodic and polishing rotation or the cathodic direction. The integrated manufacturing center has developed an automatic device for cathodic guidance (DAOC), which allows the optimized positioning of the model controlled by computer during the process of electrocoformado, which is achieved to improve the uniformity of the thickness of the material electrodepositado (Elecform3DTM).

On the basis of the 3D design, you can get the prototype in Polyjet and through electroconformado to obtain the final electrode.

Part of the research has been included within the CIT-420000-2008-25 project funded by the Ministry of education and science.