Toys with electronic devices on plastic substrates

December 9, 2009

The plastic electronics represent a new branch of the electronics whose purpose is the manufacture of devices on plastic substrates from organic and hybrid materials. This new technology gives rise to devices light of greater flexibility by facilitating their integration on certain articles and even allowing the development of devices that roll or fold upon themselves. On the other hand, it is an economic technology both by the type of materials used and the simplicity of manufacturing techniques.

The experimental development of these devices is that employs the members of the Consortium PlaseToy, Cidetec (Electroquímicas Technology Center) and Cetemmsa, with the ultimate aim of their incorporation in toys and other articles of child use. This program, funded by the Ministry of science and innovation and co-financed with Feder funds within the National Plan of development Experimental DEX-560540-2008-3, is coordinated by Aiju, Association of research of the toy industry, related and allied.

'Plastic electronic' devices to be developed in the project can be grouped in:

- Electroópticos devices: will develop three different rates, in particular electrocrómicos, PDLC (Polymer Dispersed Liquid Crystals) and electroluminiscentes (the). All of them takes advantage of the action of an electric field to bring about a different optical effect. The inclusion of these devices will make it possible to provide greater value to the final product, in accordance with the electrical compliance of application in toys.

- Flexible tactile switches: will be developed with the aim of replacing all types of keys and buttons with zones of contact within the same piece, allowing homogenize the toy, facilitating its design and avoiding the completion of additional molds. It also offers better guarantees since toy safety that prevents small pieces that can break off.

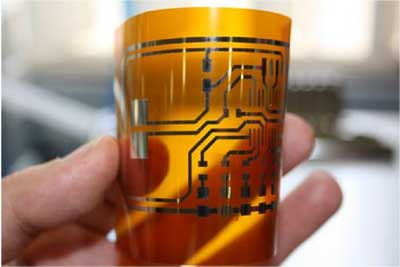

- Plastic flexible electronic circuits: the development of this kind of circuits to avoid the use of wires and welds, facilitating the design of the article, diminishing the generation of electrical and electronic waste and facilitating compliance with the RoHS directive, which is difficult to tackle with current techniques.

Polymer Dispersed Liquid Crystals (PDLC)

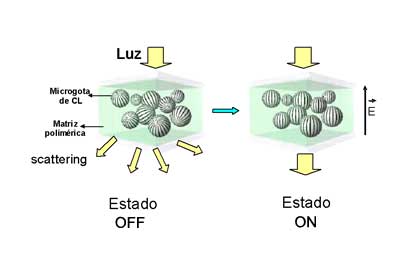

Technology called 'polymer dispersed liquid crystals' (pdlc) is based on the dispersion of micro droplets of a liquid crystal in a polymeric matrix. The difference between the indices of refraction of the liquid crystal and polymer causes a high dispersion of light (scattering) which makes that material presented a translucent appearance. When a film of this type of material is placed between two transparent electrodes and applies an alternating current, the appearance changes of translucent (off state) transparent (State on) due to the orientation of the molecules of liquid crystal in parallel to the direction of the electric field(Figure 1).

One of the main advantages of this technology are the low switching (of the order of dozens of millisecond) times, while it should be noted that do not have memory effect this State so that it requires a contribution of current not only to cause the switch to the transparent State but also to keep. On the other hand, the use of a polymer as a matrix gives them certain mechanical properties, allowing the preparation of large surface films. In addition, the polymeric nature makes it possible to use substrates plastic, allowing the manufacture of flexible and lightweight devices.

With regard to the applications of the PDLC technology, its electroópticas characteristics make it an excellent candidate for the construction of smart Windows, mainly for its implementation in the residential sector and automotive. Another more extended application is like tabs or Windows privacy controlled electrically at offices, hospitals, showcases, etc.

Drawing on the expertise of Cidetec developing electroópticos devices, have begun research works aimed at the preparation of materials and devices based on PDLC technology, not only in glass substrate, but also in plastic substrate given the advantages and possibilities offered by the latter. Composites using a mixture of pneumatic liquid crystal and a polymeric matrix of a different nature, varying parameters such as the composition and the process of separation of phases, enabling the manufacture of small devices even 5 x 5 cm square have been prepared so far.

Within the Plasetoy project, has begun to work on the development of devices with 'reverse mode' operation, i.e., that to display transparent in the 'off' State and translucent in the 'on' State by modifying the composition of the composite. Normally, the construction of such devices which operate in reverse mode', is possible through the use of liquid crystals with negative dielectric constant, which are oriented in the direction perpendicular to the applied electric field. It's much less frequent and less investigated, systems these features liquid crystal systems are less numerous. On the other hand, the preparation of the devices is more complex, requiring an additional stage of orientation planar of the material on the substrate, through the use of pre-tratadas surfaces or implementation of strong magnetic fields (> 7 T) among other techniques. It's a type of devices in development, which is still necessary to optimize various aspects and to those who are spending increasingly more research.

Electrocrómicos devices

The electrocromismo is the property with some organic and inorganic nature materials change color under the action of an electric field in a reversible manner as a result of a redox reaction. This property allows that such materials can be used as filtering systems in the area of the visible and IR (infrared) reducing the passage of light and solar radiation. This allows the use of such materials in applications such as smart Windows or ocular filters where it is important to filter both the brightness and solar radiation. Other applications of the electrocrómicos materials include displays or mirrors darken to the affect on them a certain intensity light while avoiding the glare of the driver. This application is the only one that is marketed at this time.

In general, an electrocrómico device consists of 7 layers. On the one hand, it is necessary to the deposition of an electrocrómico on a conductive plastic substrate material. The material electrocrómico may be of organic nature (e.g. conductive polymers) or inorganic (metal oxides).

For the correct operation of a device electrocrómico need a material capable of being source and recipient of ions, necessary to offset the burden of the layer electrocrómica. In addition, depending on the change of color obtained by the electrocrómico material will be used a proper contraelectrodo based on inorganic oxides or conductive polymers, so that the change is preferably between a transparent and a colored State. Finally, both layers are separated by an electrolyte which allows the passage of ions between them.

From Cidetec has been an important innovation in the field of the electrocromismo to simplify the number of layers required for the operation of an electrocrómico device. To this end, a formulation that includes an electrocrómico material, an electrolyte and a couple re-dox of material electrocrómico, then from 7 to 5 layers, significantly simplifying the manufacture of the devices and reducing the final cost has been developed.

This project deals with the use of the technology of electrocromismo combined with the preparation of lithographs on plastic substrates for later integration in toys, so that it can perform specific designs for decorative purposes.

Finally, the preparation of devices hybrid combining electrocromismo and liquid crystal technology is addressing. Thus, it is possible to have a prototype with four different optical effects: transparent colourless, transparent coloured, translucent colorless and translucent colored.

Flexible tactile switches and flexible circuitry

In recent years have been arising new concepts in terms of electronic technology such as 'plastic electronics', 'printed electronics' or 'organic electronics'. These techniques are intended to provide new methods of manufacturing posed a revolution in the electronics and microelectronics. Basically it's use and adapt the traditional technologies employed in arts graphic such as silkscreen, lithography and inkjet printing and roll-to-roll, among others, to make electronic devices traditionally developed by other techniques. The printing of electronics means new chemical developments for this technology such as for example, conductive inks, resistive inks, inks insulators or inks semiconductoras. There are already on the market commercial inks designed for 'printed electronics' as well as substrates for printing them. It is a promising technology, constantly evolving and with success already in the market.

The main applications of flexible electronics are: sensors pressure, flexible circuitry, devices OLED, flexible reports, electroluminiscentes lamps, flexible batteries, electrophoretic, RFID tags, sensors elastic, flexible photovoltaic panels, devices among others. Flexible electronics can bring to the toy industry new products with greater flexibility and the possibility of even replace the usual wiring employee in conventional electronics.

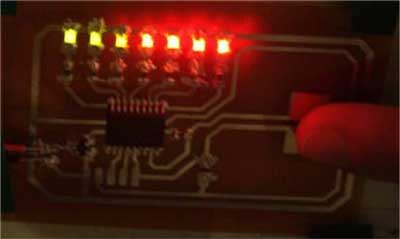

From Cetemmsa has been printed using inkjet technology pressure sensors with the functionality of on/off switch and the printing of the circuitry necessary for the proper functioning of the sensor, with the inclusion of several LED not hybrid (conventional) for the demonstration that the printed system works properly and to check that the 'printed electronics' technology It has a place in the toy industry.

Electroluminiscentes devices

The electroluminescence is a phenomenon whereby a material emits light when an electric field is applied. The electroluminiscentes devices are structures sandwich where the luminescent material is located in the interior.

The electroluminescence has a wide range of applications, from electronic products such as phones, PDAs, watches, to accessories of toys, decoration, advertising, signage road and conventional, among others.

In Cetemmsa has been the construction of devices electroluminiscentes with flexible plastic substrate base. These systems have been deposited by screen-printing, this technique allows the realization of devices from a variety of size and design. These devices emit different colors depending on the phosphorus entered the system, can emit white light, blue, green, Orange, among others.

Plastic electronics in toys

The toy industry is a sector that is being widely affected by the importation of products from the Asian countries. Their designs are apparently plagiarized and existing trade rules do not provide reliable solution to the acquisition of articles that do not comply with the rules of established standardization. As a result, the competition based on cost reduction is not feasible at the present time.

In addition, the design of new articles of toy and children's is slowing markedly due to the crisis at the present time many European and international sectors.

Currently available tool for companies to maintain their market share is, invariably, the livelihood of their competitiveness through research and development of new technologies that bring dynamism and interactivity to the developed articles.

The plastic electronics have the potential to revitalize the economy, create new jobs and contribute to public health, since they allow saving time and costs, and contribute to increase the functionality of various sectors (consumer electronics)(, construction, automotive various lighting devices, logistics and even fashion). Manufacturers to introduce these devices in their articles incorporated into its range of differentiating agents products on the market today, contributing to innovation, competitiveness and sustainability of the sector.

For this reason, the technological Institute of the toy (Aiju), is interested in this line of development of technologies of 'plastic electronics', with the ultimate goal of incorporating important technological innovations, beyond of the creations that are carried out periodically, which can bemedium-term, a great technological leap and competitive connection to other competitor countries. During 2009 and 2010 is will continue research in this project in order to meet the objectives set.