External measurement of the flow for the effective prevention of the production of non-conforming parts

December 9, 2009

The seal of some of the for restraint circuits connected in parallel is especially critical, because it is often difficult to detect with production underway progressive process. A good example is the gradual reduction of the section of channels for the accumulation of dirt, causing a slow and, therefore, virtually imperceptible deterioration in the quality of the pieces. In the case of crushed tubes or other similar defects, the effect on the flow is more immediate, although in this case the loss of quality of the parts is evident most afternoon.

Technical explanation

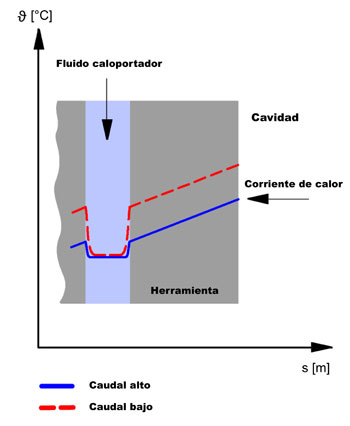

The heat transmission on the walls of channels for restraint is closely related to the flow conditions, which in turn are basically dependent on the flow. The variation of thermal differential between the fluid caloportador and the mold is also reflected on the surface of the cavity. As a result, the flow of the fluid has a direct effect on the surface temperature of the cavity, which is an important parameter for quality (Figure 1).

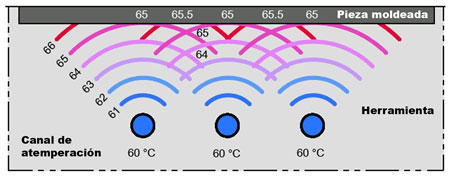

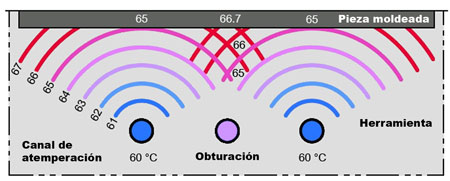

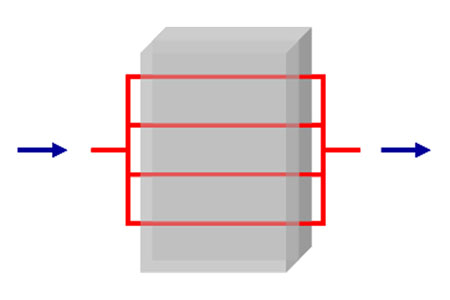

Now, if it varies the flow in one of the channels connected in parallel, thermal defects in part increase inevitably, the thermal distribution on the surface of the cavity is deficient (figures 2 and 3).

Connection in series or in parallel circuits for restraint?

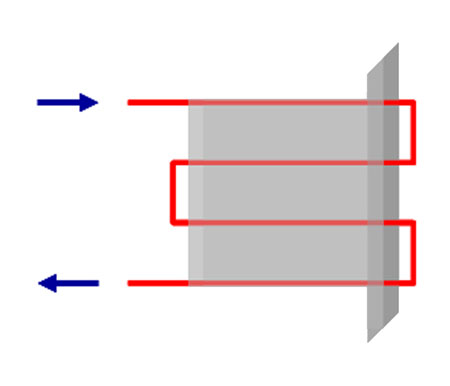

Both types of connections have their advantages and disadvantages, as shown in figures 4 and 5. The circuits connected in series, for example, guarantee equal conditions for all channels with a seal of reduced risk, offering a high process reliability.

Monitoring of flow and temperature of the mold is relatively simple, and connections can be very easily. For restraint circuits connected in parallel, on the other hand, have less losses of pressure and thermal differences are minor.

Monitoring of the flow of all circuits for restraint

In applications that circuits for restraint are connected in series, flow monitoring systems that offer the atemperadores series is more than enough, as it is the case of the HB-Therm teams. However, to obtain meaningful data in applications that have connected circuits in parallel, it is recommended the installation of an external flow-meter, like that, it offers HB-Therm as accessory for the current Series 5 models, perfectly adjusted to the process for restraint of this series (figures 6 and 7).

The external flow-meter is suitable for atemperadores of water with a temperature of up to 160 ° C. Its range of measurement is 0.4 to 20 l/min for each circuit, and works a ultrapreciso ultrasonic measurement system with no moving parts in the branch of return of the circuits. To measure the temperature, it consists of a common thermal probe in the line of output with separate probes into the branches of return of each one of the circuits for restraint. The data CAN interface allows an easy and direct connection to the atemperadores Series 5 of HB-Therm. For applications without data interface are a signal of frequency for each circuit.

Basic equipment: four expandable for restraint circuits

In its basic equipment, the external flow meter has 4 circuits of measurement, which can be extended to 8 through an additional distributor block. Like all products of the House HB-Therm, the component is manufactured entirely with corrosion-resistant materials. The external flow meter can be installed easily on the back of the atemperador; control, instrumentation and monitoring functions are integrated in the control of the atemperador system. All Electronics analysis is directly mounted on the device. The adjustment of the limit values works completely automatically, so it is not necessary to make the adjustments manually for each of the molds. The applied limit values are calculated from the existing conditions after the boot of the machine.

In special cases, the external flow meter can also be installed completely separate from the atemperador. The location, mounting, and the connection can agree form customized with the client depending on the specific requirements of the application.

Advantages for the user

The main advantage for the user of this external flow-meter is the possibility to monitor separately several for restraint circuits connected in parallel. In addition, the thermal performance of each of the circuits, due to the thermal probe of return that incorporates each of them can be monitored with the teams of the Series 5 range. These important parameters of process control is another step towards the achievement of a high constant and uniform quality of the pieces in the production of molding by injection.

Conclusions

To reduce the risk of shutter, circuits for restraint be connected in series. If a provision at the same time, however, is recommended to measure and monitor the different circuits. In this context, the company argues, "the external flow of HB-Therm is the most effective and simple solution".