This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

¿Nuevos materiales en el sector juguetero?Aiju works on a project that studies the properties of biodegradable materials

New materials in the juguetero sector?

Ana Ibáñez, Asunción Martínez and Ana Sánchez (Aiju)30/10/2009 October 30, 2009

The plastics industry is one that has most evolved during the 20th century, especially in the fifties. Since its inception, the plastic has been used in the manufacture of toys by various factors (acceptable cost, easy workability, possibility for complex forms, among other reasons). This article reviews the history of the plastic in the juguetero sector until his last big challenge: bioplastics.

At the end of the 20th century, the price of oil fell, and likewise declined interest in biodegradable plastics. In recent years this trend has been reversed. There is a combination of factors that are driving the growth and acceptance of biodegradable resins, as well as be an increase in the price of oil, has been greater awareness that the oil reserves are running out of an alarming. These concerns are often accompanied by environmental legal and political measures, for it is increasing the collective effort to achieve a reasonable balance between development and ecology.

Research on biodegradable materials are allowing the development of new applications and the number of companies that are beginning to use such materials is growing. There is a marked increase in scientific and industrial interest in the research for the production of biodegradable plastics or PDEs (environmentally degradable polymers and plastics).

Currently, most consumed plastics in the toy industry are the polyolefin polymers of styrene, plasticized PVC and some technical plastics

Plastic materials with biodegradable characteristics

In this context, from the technological Institute of the toy (Aiju), a project whose goal is to offer a range of plastic materials with characteristics of biodegradable, both commercial and non-commercial sector is carrying out. The aim is in this way, give the sector a suitable range of materials which may be available for the design and manufacture of innovative and differentiated, products with biodegradable, not present on the market properties.

Currently, most consumed plastics in the toy industry are the polyolefins (polyethylene, polypropylene, EVA...), derived from styrene polymers (PS, ABS, SB...) and plasticized PVC. Some technical (like polyamide, polycarbonate or polymethylmethacrylate) plastics are also used in certain components or parts of toys.

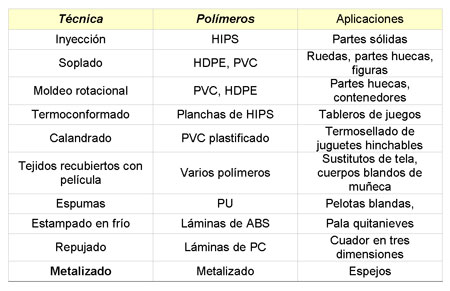

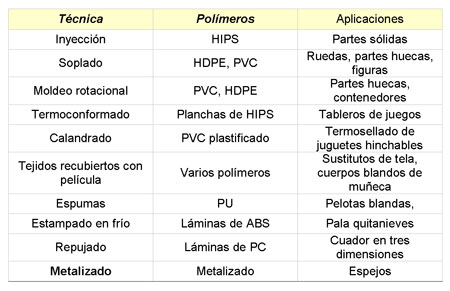

Table 1. Techniques of processing in the toy industry.

The most common techniques of processing industry of the toy (table 1), one of the most used processes is the injection process. For this reason, the commercial materials selected in this draft have been materials with high fluidity, suitable for the injection process.

Selected business materials have been:

- Polymers based on natural starch: MaterBi YI01U.

- Biodegradable polyester: HBP P 226 (polihidroxibutirato HBP)

- Polyvinyl alcohol

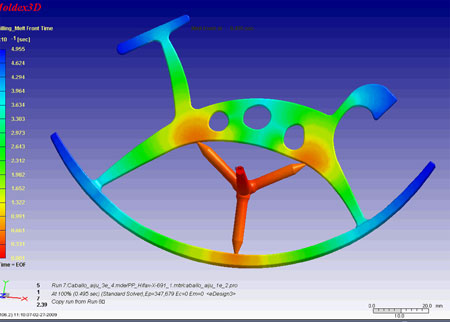

Figure 1. Simulation of the process of filling of the P226 HBP.

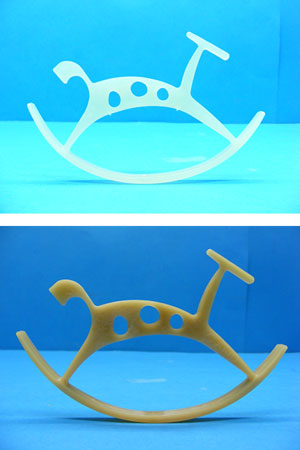

Before the first testing of injection is simulated phases of filling, compacting and cooling of the process of injection of the different biodegradable materials used (Figure 1). The analysis showed that the selected materials had no problems in the processing. Figure 2, shows some of the injected parts.

Figure 2. Injected parts.

The development of test standard for testing of traction, flexion and impact and the pieces obtained from the template prototype has been an injection machine Demag Ergotech 110-430 h/310V. There has been particular interest in the parameters of injection of time and temperature processing given that these materials can be affected by these factors. The temperature of the injection process has been 140-190 ° C.

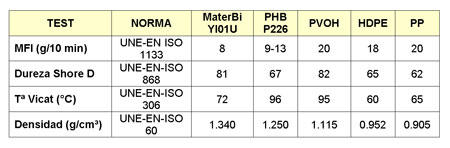

Below, we show the physical and mechanical properties of biodegradable materials selected against (RIGIDEX HD 5218) HDPE and PP (ISPLEN PB180):

Table 2. Physical properties.

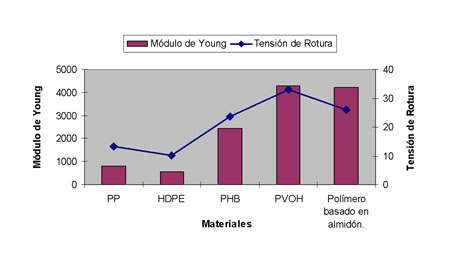

Figure 2. Properties of traction.

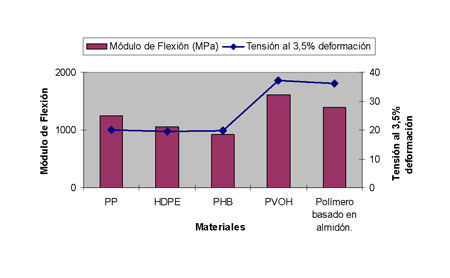

Figure 3. Properties of bending.

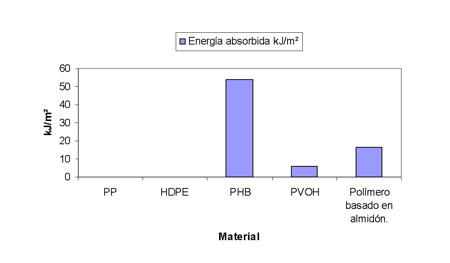

Figure 4. Properties in Charpy impact without entalla.

In view of the displayed results, these materials can be injected without problems. The biodegradable materials are different to conventional plastics physical and mechanical properties.

The biodegradable materials are more rigid and fragile than HDPE and pp is certain that, if you compare the mechanical properties of biodegradable materials with the of the thermoplastics trading, it is possible that there are some limitations for some applications in particular. However, more and more, the production of these materials companies are developing more resistant plastics with lower costs.

Little by little, bioplastics will find their place in the world of the toy industry and from Aiju it supports and promotes the use of these materials

The juguetero sector, composed in 97% of SMEs, is aware of the need for innovation and improvement of its products and processes. Precisely because of the need for novel articles should bet by the use of such materials that offer more features of biodegradability. Little by little, bioplastics will find their place in the world of the toy industry and from Aiju it supports and promotes the use of these materials.

ThanksThe activities developed in this paper have been funded by the Institute of medium and small industry Valenciana (Impiva).

Related Companies or Entities

AIJU Instituto tecnológico de producto Infantil y ocio