A knee replacement for everyone

July 7, 2009

It has become, for both, in a challenge to industry providing patients of high quality products at an affordable price that can effectively improve the quality of life.

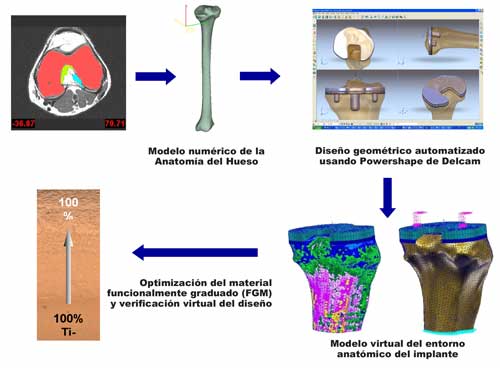

The European project Custom-Fit accepted the challenge through the achievement of a new paradigm of production can generate fully customized products at an affordable price. In General, the Custom-Fit process starts with the capture of the geometric characteristics of the patient using MRI (magnetic resonance) and CT (computerized tomography) scanners. A CAD (computer aided design) program specialized adapts the design of an implant standard to the individual features of the patient, taking into account also other additional information required to personalize the implant, such as the distribution of specific load of the patient. Finally, the customized part is made of new additive technologies (Rapid Manufacturing) developed, perfectly suitable for the manufacture of exclusive products.

At present, the scope of the Custom-Fit products is quite large, not only for medical applications but also for consumer products. The project used various case studies in addition to the implant of the knee: a mandibular implant and a transfemoral prosthesis, in the medical field of application, and other unusual consumer products where the customization has shown to provide added value, as cases of motorcyclists and motorcycle seats.

Exact replica

A specific component is designed for replacement of the knee: the tibial base plate, a part of metal that replaces the final top of the bone of the tibia (see image 1).

The perfect geometry of this part of the bone of the tibia adjustment improves the stability of the patient. This is obtained with a design tool appropriate (developed by the partner of Custom-Fit Delcam) which automatically calls into question the CT scanner in 3D of the tibia of the patient, provides the most appropriate bone surgical cut and designs the plate tibial base that better fits the section of the bone.

Custom-Fit technology also enables the manufacture of a plate of metal material graduate, optimized for the specific loads of the knee on the basis of the patient. This is possible thanks to a new technology of 'rapid manufacturing' called ppm (process of metal printing, developed by the partner of the Sintef Custom-Fit), which is able to perform a graduate part mixing it and Co-Cr. For reasons of biocompatibility, it is preferable to have titanium on the part of the round dish to the tibia, insofar as the alloy cobalto-cromo on the opposite side guarantees its resistance.

There is still a long way before its actual implementation on a patient, but the results of the design and manufactured evidence are very promising. The Custom-Fit approach seems to be the solution to make implants the future knee.