New tools and applications for modeling of sheet metal parts

June 12, 2009

This release is the second version of Solid Edge that incorporates the revolutionary technology Synchronous Technology of Siemens PLM Software, that allows the modeling based on operations without the need for historical and serves as a fundamental tool for helping clients to react more quickly to changes in the market.

"" We were looking for something very flexible… but also something with all the power of modeling of 3D operations for the modification of the components of the machine, "in the words of Ben Fune, 'process engineering manager', American Renolit Coorp.""We have found the best of both worlds in Solid Edge with Synchronous Technology".

Solid Edge is a basic component of the Velocity Series family and combines the speed and flexibility of direct modeling with the precise control of the design. The latest version further extends the application of Synchronous Technology with capabilities of modeling of parts and Assembly as well as a new application of design of sheet metal parts. With this release, Siemens PLM Software also announces a new FEA simulation tool and the update of the management of documents Insight tool, taking advantage of the latest Microsoft SharePoint platforms.

"The release of Solid Edge with Synchronous Technology 2 - SE TS2 - shows the expansion of the innovative Synchronous Technology of Siemens PLM Software in the areas of modeling of parts and Assembly, including the intelligent design of sheet metal", as says Ken Versprille, PLM Research Director, CPDA. "In our review of last year, we are positioned Synchronous Technology as an important step in the modeling of solids and predicted its positive impact on the industry." This latest confirms that we were right, to reinforce the strength and solidity that shows as a modeling program. Interviews with users prove the benefits that have succeeded in reducing design cycles. These modeling advances found in Solid Edge, combined with the introduction of a new ugly application of mid-range, Solid Edge Simulation, and the continuous improvement of the management tool of data Insight of Siemens PLM Software taking advantage of advances in the Microsoft SharePoint", it offers a 'win-win' for Solid Edge scenario and its users".

New application of design of sheet metal parts

Solid Edge now applied Synchronous Technology for sheet metal parts design, creating an application's design 3D without historical based operations also for modeling of metal sheets. Sheet metal design is the second application that uses the potential of Synchronous Technology (since its announcement in December, CAM Express takes advantage of the features of Synchronous Technology) and also validates its extensibility. Synchronous technology brings new levels of productivity to your sheet metal design environment so that users can create models with less pre-planning, make the changes with unlimited flexibility and reuse and edit data providers more effectively.

"A process application specific as the design of sheet metal is a good example of a design discipline that requires a set of specialized skills and unique features in the software," said Dan Staples, product development director of Solid EdgeSiemens PLM Software.

"Now our designs of sheet metal parts can be a tremendous savings in time with Synchronous Technology." "And now that Synchronous Technology has been incorporated in the design of sheet metal, you can see how extensible is this technology actually".

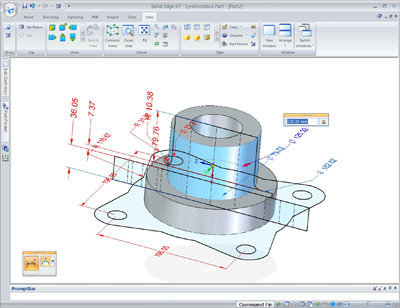

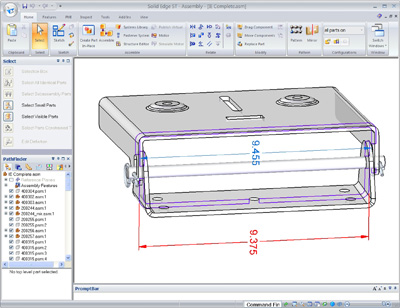

Synchronous Technology and the modeling of assemblies

The new version of Solid Edge broadens Synchronous Technology in the modeling of the parts and the Assembly for the creation of complex applications and advanced editing tools of patterns that reduce the time of global design. To improve the migration of data from 2D to 3D, Solid Edge makes the 2D dimensions of planes imported into 3D driving dimensions during the creation of the model, so users can edit the imported from 2D-based 3D designs. In addition, a new function 'Active section' can be used to simplify 3D model changes leaving users to edit sections of 2D cross-section through any part of a 3D model, and update the 3D model in real time.

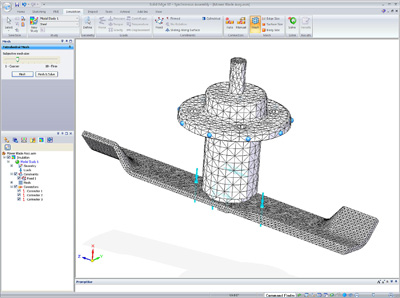

New Solid Edge Simulation for FEA

Solid Edge Simulation is a new optional analysis tool integrated in the CAD system that enables validation of the design of parts and assemblies in the process of product development to achieve a faster way out of the market and a reduction in costs of physical prototypes. It is based on the modeling of finite element of Femap and NX Nastran technology, Solid Edge by incorporating in the user interface. It is easy for designers and engineers to use and promote greater use of simulation in Solid Edge, promoting design innovation. Solid Edge Simulation also expands Synchronous Technology to facilitate the preparation of the model and accelerate the refinements of the design.

"" This economic situation requires engineers to do more for themselves than ever before they had done, "said Bill Mc Clure, Vice President of 'product development' for Velocity Series, Siemens PLM Software."Through the incorporation of FEA in Solid Edge can be simulated more designs in less time and minimizes the need to outsource the analysis. "This allows companies to respond to customers faster, with higher quality and lower costs."

Solid Edge with Insight for the management of the design with Microsoft SharePoint data

Solid Edge now provides key advances to improve the integrated Insight Management application of the design data, a key element of the strategy's Velocity Series to offer a scalable PDM, which also includes the platform Teamcenter Express.

"" Solid Edge Insight running on SharePoint Server eases the management of the design data for business collaboration for small and medium-sized businesses,"says Don Richardson, director, Global Innovation and PLM Industry Strategy, Microsoft."Siemens PLM Software, is it for a long time, a partner of Microsoft. "Microsoft SharePoint has been using since 2001, and it continues to implement the latest Microsoft technologies in your PLM applications to meet the needs of its customers."

Solid Edge with Insight leverages the latest Microsoft platform

SharePoint for collaboration, faster workflows and enhanced security capabilities offered by Windows SharePoint Services (WSS) 3.0 and Microsoft Office SharePoint Server 2007 (MOSS). Solid Edge with Insight uses SharePoint from the first version was introduced in 2001 and now has more than 1000 customers. Bring Insight to the last platform helps users reduce the PDM deployment and support costs. Microsoft SharePoint is especially popular in small and medium-sized enterprises (SMEs) currently with more than 100 million jobs worldwide.