The dimensional verification of 3D models

On the other hand, during the transformation of plastics processes there are various parameters to control in order to obtain parts with optimum quality, the modification of any of these, such as temperature and pressure, it can affect the size of the final productleading to products outside of the specifications that demand the client.

Companies that are certified or who want to meet the requirements of the ISO 9000 quality standard must demonstrate its ability to supply products and/or services compliant; one of the main points to control, both by manufacturers of molds for plastics processing firms, is the dimensional control of products, i.e., that the final product complies with the tolerances specify in the design phase.

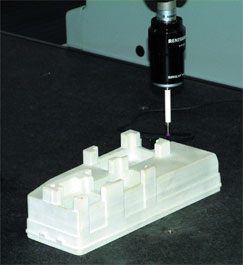

Among the possibilities that exist at present for the dimensional control of moulds, is through dimensional transducer measurement. For this reason, and as a result of the detection of a need to manifest in the moldista sector and transformation of plastics in the inspection and verification phases, AIJU has made available of the undertakings a dimensional metrology of latest generation servicewhich is intended to provide companies with an efficient service in a short period of time.

Within the Department of product and test engineering is available a measuring machine CMM coordinate, with useful dimensions of x = 900 mm, and = 1200 mm and z = 800 mm, maximum permissible error of (1. 7 + L/333) MicronL in mm, being the maximum weight of the piece to 1300 kg. This CMM offers the possibility of measuring shapes, dimensions and the position on a single machine. The main features of the team are: the ultra rigid bridge entirely from aluminium, the TRICISIONTM of the bridge design increases the mass/rigidity ratio to achieve greater accuracy and long-term stability, the table is made of one piece and constructed from granite to withstand vibrations"variable rigidity" elastomeric damping system provides a high isolation from external vibrations, unhindered access from all sides, rules of high resolution with official certificate of the coefficient of thermal expansion, etc. He works in a temperature range of 18-22 ° C, with linear thermal compensation.

Services are underway with the dimensional verification team ENAC (national accreditation entity) calibration certificate.

Dimensional metrology:

- Inspection advanced forms by comparison with the CAD model or specification of level.

- Evaluation of geometric tolerances

- Comparison of the performance of the moulds between two samples to determine whether the mold is producing parts according to specifications, being able to indicate that changes are needed in the design of the mould, in which case this mold producing pieces out of tolerance.

- Flexible sheet metal and profile verification.

- Obtaining cloud of 3D points of the model for further treatment.

- And in general the dimensional verification of any piece.

The provision of the services of dimensional metrology aims to solve the problems of the inspection and verification of companies moldistas and processing of plastics, providing a complete and perfect service to the industries that adapts to the technical requirements demanded by the industry