Guzmán polymers in Plast 2009

February 26, 2009

In the field of centralized facilities for the extrusion sector, MainTech has developed a special installation for the estocaje, feeding, dosing, recycling and filtering of crushed polystyrene, which can create big problems for processing.

The optimized utilization of discards of production for reuse, is today a strategic importance given the high cost of the raw material Virgin.

For this reason, manufacturer of auxiliary systems MainTech, planned especially silos with patented extraction systems, pneumatic transport controlled density, control systems with automatic regulation of the flow of air and vacuum, silos of small dimensions for light granules, loading of the thermoforming with mechanical extraction systems, dispensers placed on the extruder to maintain the required production, etc. With respect to the material sheet or light comes the need for specific developments such as those described in this article.

"Some of the new machines of MainTech were exposed during the last K, Fakuma and Equiplast, but during the next exhibition Plast in Milan will be presented the full range of transport, dosage and estocaje," thus indicated by Renato Pegoraro, MainTech administrator.

"It's simple equipment, low-cost calling a particular technology for the processing of the materials." "In addition, it is very useful to optimize the recovery of materials to obtain a competitive product sales margins are very low and maximum possible material recovery is needed to keep production costs low."

These lines do not only work with recycled materials, and make up 60% of the total of the material used, consisting of: cuts of plates from the process of thermoforming physically located below and shredded material that the transformer is at a low price. All the cuts are extremely light and tend to sticky blocking the transportation system and dosing. It has been necessary to explore effective extraction systems in correspondence with storage silos, containers collection and with the entire facility of transportation.

All of this taking into account that the extrusion line has reached a flow equal to 1500 kg/h and is therefore necessary to store, transport and measure about 750 kg of material at the time.

Storage and loading of materials

Two external silos for the storage of polystyrene Virgin (of 55 cubic metres) for the line of production and two internal silos (3,4003dm) containing high polystyrene impact. A system of loading of silos that allows to do it from big bag or classic bag of pellets or tanker.

For difficult to treat from the remains of the thermoforming recovered material, it is stored in two large 24 cubic metre silos. The latter are based on a unit defined as ' rotating system of extraction of recovered '. In practice, in the interior of the silo is installed a rotating system of large dimension that, depending on the call of the suction (from the line of vacuum) system, operated with a spindle, which adds the material on the basis of the own density. This system consists of a central shaft surrounded by two helices and a central cone material that leads to the mouth of extraction, where the spindle is located. The entire facility is managed by a PLC.

Silos for crushing feed from a station for the download of such material; the station consists of a system of extraction with spindle and a system of vibration allowing transport and dosage of the material.

Any other material comes from the line for thermoforming, is collected in big bags, and first passes through a large shredder manufactured by MainTech. It is located in an area of the factory where the collection of remains of the process and particularly voluminous internal descartes has centralized. The mill is fed automatically and two silos collected the crushed material transported by vacuum line.

Feeding and dosage

All the materials emerging from the various silos described above are transported through a system of rigid pipe to the central of manual control where different materials are selected will be stored in the unit of Gravimetric dosing on the extruder.

The Gravimetric dosing is a unit for five components that allows a capacity of 1,500 kg/h and is programmed to measure two recovered materials (PS Crystal and high impact), two virgins polystyrenes and a dye. It is placed on a correctly dimensioned structure located on the extruder.

Dosing unit becomes directly into the hopper of food forced, necessary due to the lightness of the material in the form of scales to maintain a correct and continuous feeding of the extruder.

At the end of the line there is a small mill to crush the remains of the line and sent to a container by means of a flexible screw directly feeding the extruder.

Through loading system empty

The burden of the materials is done through a large vacuum unit. A zone is dedicated to the pump for the burden of the silos of storage granules and recovered, with aspirations in several points, and another for loading dosing unit, with a third in reserve to replace immediately in case of any discrepancies.

Auxiliary systems control

The entire facility is managed with a central control with PLC 'master', equipped with a touchscreen color where all the elements of the installation are represented graphically.

The PLC communicates with each machine line control serial called Touch Sys, developed by Main Tech. This system allows to know all the historical alarm installation and see the intervention of the operators. Control over the Gravimetric dosing, vacuum generator and the consumption of materials, registering the present at that time volume in silos.

The computer control system is used by MainTech in each and every one of facilities which performs and is adjusted according to the requirements of the customers. It can be controlled by a PLC or a computer at a point or at various points the company's connected through a dial-up module.

Rapid presents the full range of the 600 series

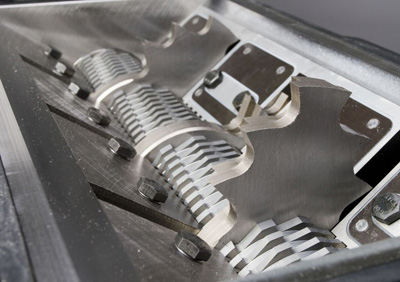

Rapid Granulator AB presents the full range of the 600 series with the addition of the largest design machine 'open heart', the model 600-150. These innovations of saving time and cost for inyectadores and processors will have a leading role in the presentation of the company.

Also shown are of the 100 series of Rapid, a completely new line of low-speed equipment, Mills without grid with metal detection integrated for applications at the foot of machine, specifically designed for grinding hard and brittle materials. The catalogue of these teams comprise eight models basis; the smallest one to deal with rejections such as lava flows and remnants of the production of bearings and the larger capable of grinding components very large bumpers and dashboards, for example. All models are equipped with 'smooth mesh' to ensure operational stress absorption and prevent damage to the engine and gears.

The 100 series is also provided with a system anti blockade, which not only prevents the block in the Chamber of court, but it allows thicker products can be crushed.

Continuing the success of the series ' open heart ' 300, 400 and 500, is complete the range of the series 600 heart open with 600 mm rotor diameters and is available in three widths; 900, 1200 and 1500 mm, and can reach capacities of up to 2500 Kg/h. In addition, the 600 series can be equipped with the camera of tangential Super Court of Rapid, allowing that the machine can work with pieces larger than indicated for current rotor diameter.

Rapid Mills 'open heart' are suitable for power stations of large volume or crushing on site of injected parts, remains of blown or extrusion, or rejections for direct recycling. They all use the technique of cutting of Rapid, which includes the action of double scissor cutting and the constant circle of court, to produce granules of uniform size with a minimum content of dust, even with the toughest materials.

Also presents the system Modular Silencing System (MSS) of Rapid. Due to the increasingly greater noise restrictions applied to the working environment for national and European regulatory authorities, the MSS offers an innovative solution for noise reduction processors and OEMs.

MSS can fit virtually any machine configuration and reduce emissions of noise between 10-20 dB (A). Although designed for use with mills for plastic and their transport systems, MSS apply to almost all types of machinery that emits noise reducing noise levels during operation and improving schemes of health and safety at work.