Incorporation of natural waste for the manufacture of toys

In this context, the Technological Institute of the toy (Aiju) has developed a project funded by Social work CAM on the incorporation of natural waste plastic materials whose main objective is the incorporation of shell of almond, renewable natural residue, to formulations of plastic materials in order to obtain a material with new propertiesmechanical, environmental, etc., for the manufacture of toys looking wood, innovative and differentiated, with a few additional properties not present on the market.

These natural reinforcements ensure a total recyclability as they decompose easily without presenting any type of toxic waste. The incorporation of this natural reinforcement incorporated into plastic formulations greater rigidity and tensile strength and lower resistance to impact.

The toy industry

Toys are usually a relatively short life cycle and are discarded after few years. This problem is compounded the difficulty of disassembly. For this reason, is necessary research and innovation in the juguetero sector, to improve the products and adapt them to current requirements of sustainability. The incorporation of almond shells allows to reduce the cost of the final product due to the partial replacement of the plastic material and on the other hand, from the development of different ecological plastics, which do not come from oil, new values are entered to the toys and their users, such as respect for the environment and natural resources.

Description of the work plan

This has been necessary to a process of selection of plastic materials, study of their compatibility with the shell of almond, the preparation of different formulations of composite with different percentages of shell of almond and its physical and mechanical characterization.

Products used

Used almond shell has been the 'marcona' variety. The entire supplied skins are trituraron for their incorporation into formulations of HDPE and PS to reach a size of particle to submit not difficulties of passage through the mouthpiece of the extruder and facilitate the process of mixing (Figure 1).

For the preparation of these formulations are added an compatibilizador agent (Polybond 3009).

Experimental conditions

The mixture of thermoplastic resins and compatibilizante agent with the almond shell was conducted in an extruder with main entrance for material base and side for reinforcement. The outgoing rows of the extruder is subsequently proceeded to grancear. Mixtures of composites obtained is dried before the process of injection to 80 ° C for 72 hours.

• Injection of thermoplastic reinforced with almond shell

In order to analyze the effect of the shell of almond as reinforcement of plastics, is injected test tubes of tensile, flexural and impact. The temperature of the injection process was 190 and 200 ° C in the case of the formulations with HDPE and PS respectively.

Results

He was the study of the (mass loss) breakdown of both materials containing in shell almonds from 45 per cent depending on the temperature. The temperature increased at a speed of 20 ° C/min.

In order to see the spread of dust from shell of almond in the matrix, was a scanning electron microscopy.

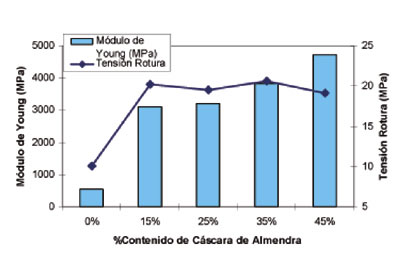

Shows that by increasing the percent of almond shell hardness increases slightly since this variety of almond has a very hard shell. Also density increases with the content of shell, as well as the temperature of softening, indicating that the burden slightly reinforces the material. Fluidity index decreases, however the incorporation of the shell makes the mixture more viscous and flows less than the material without charge. Vary the content of shell of almond in the formulations yields a significant increase in the modulus of elasticity that the incorporation of almond to HDPE husk, increases the rigidity of the material. It notes that resistance to rupture of materials with almond shell is also higher than the HDPE without strengthening, and the resistance value obtained is similar with shell between 15 and 45 percent content.

Conclusions

Studies have shown the possibility of mixing and processing through conventional, such as extrusion and injection methods, made up of plastic with peel of almond in proportions of up to 45%. The incorporation of shell of almond, renewable natural resource to formulations of plastic materials shows good perspective from the technical and economic point of view.

The visual appearance of the resulting outputs of this partial substitution has been similar to the wood, with the advantage that, unlike this one, the almond composites can transform plastic, that is, without having to modify the production lines.

On the other hand, through the use of the almond shells intended this waste a significant new use at industrial level.

Commercial applications of the products developed are very broad, from decorative objects, outdoor furniture, elements of game in playgrounds, containers of objects and games table, etc.

The incorporation of a 15 per cent of almond shell obtained an increase in the modulus of elasticity. However, an increase of the content of almond up 45 percent shell causes a slight decrease from the rigidity of the material, still below the PS without load. It also notes that the strength of materials with almond shell is greater than the PS not reinforced.

The impact resistance decreases with the addition of almond shells increased the rigidity with respect to the plastic material only. This behavior can be improved through the use of additives to improve this property. In order to demonstrate the feasibility of processing, are injected prototypes of toys (Figure 8), which corresponded to an already existing in the market piece, made of another material.