This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at Sinterizado selectivo por láser

The variables that influence

Selective laser sintering

Louise Vidal, Asunción Martínez

Dept. product engineering and testing of AIJU15/05/2002

Dept. product engineering and testing of AIJU15/05/2002

Rapid prototyping

In order to achieve a certain technical properties in the pieces obtained through prototype selective sintering (SLS) laser, depending on the required specifications, has been in AIJU a study of the variables that influence the process of sintering.

The results obtained during the study of the materials used in rapid prototyping using SLS technology are included in it as a continuation of the work presented in the previous issue. Has been used so a team of selective sintering Sinterstation 2500 Laser System and the parameters have changed: power of the laser and temperature of work, insofar as they may determine the characteristics of the obtained pieces.

Given that in the first part of the work were presented the results obtained with polyamide and the influence of the power of the laser materials of sintering, in this second part of the work include the results of the influence of the temperature of sintering in the final mechanical properties of sinterizadas polyamide parts.

Given that in the first part of the work were presented the results obtained with polyamide and the influence of the power of the laser materials of sintering, in this second part of the work include the results of the influence of the temperature of sintering in the final mechanical properties of sinterizadas polyamide parts.

Part II: The influence of the working temperature

He has been the study of the influence of the "temperature" in the House of sintering on the mechanical properties of polyamide no-load mineral materials. For this test tubes have sintering for its characterization using a 12 W laser power. This value is selected on the basis of the results of the above-mentioned study.

The "temperature" parameter is the temperature that exist in the interior of the House while occurs the sintering of the pieces, and this temperature has varied in the following range of values: 174, 175, 176, 177,178 ° C.

Here are the results obtained in each test, as well as the obtained conclusions about what is the value of the working temperature is the most appropriate for certain properties in the material.

The "temperature" parameter is the temperature that exist in the interior of the House while occurs the sintering of the pieces, and this temperature has varied in the following range of values: 174, 175, 176, 177,178 ° C.

Here are the results obtained in each test, as well as the obtained conclusions about what is the value of the working temperature is the most appropriate for certain properties in the material.

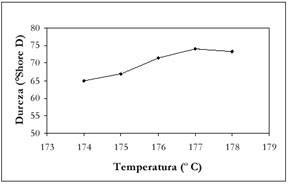

Hardness Shore D

Figure 1 shows that the hardness of the material increases the greater is the temperature, presenting similar hardness from 176 ° C values, because at lower temperatures the layers of the material do not acquire the same cohesion that is achieved with higher temperatures.

Figure 1. Variation of hardness Shore D depending on the temperature of work.

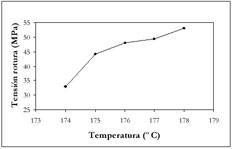

Traction test

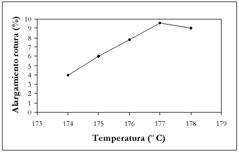

To increase the working temperature is observed that both the tension and elongation at break point are also increasing (figures 2 and 3, respectively). From 176 ° C the material presents a greater resistance and is capable of more deform without breaking.

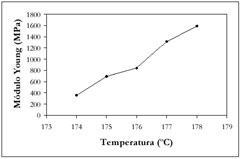

The results obtained for the Young's modulus (Figure 4) also have the same tendency with the temperature, indicating that the material is more rigid with increasing temperature.

The results obtained for the Young's modulus (Figure 4) also have the same tendency with the temperature, indicating that the material is more rigid with increasing temperature.

Figure 2. Variation of stress at fracture according to the working temperature.

Figure 3. Variation of elongation at break in

the role of the working temperature.

the role of the working temperature.

Figure 4. Variation of Young's modulus on the basis of the working temperature.

Compression test

Results from trials of compression (not including the graphics) presented a trend similar to those obtained in the trial of traction, the values of stress and deformation are higher for samples sintered with elevated (from 176 ° C) temperatures. Also the compression module has a tendency to increase the temperature of work.

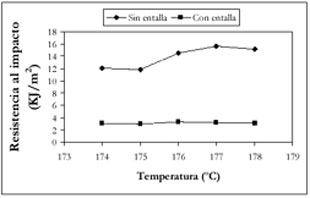

Figure 5. According to the working temperature impact resistance.

The Charpy impact resistance

The results of resistance to impact both with entalla without entalla are included in Figure 5. For the samples without entalla there is a light tendency to increase with the working temperature. Higher values have been obtained with temperatures from 176 ° C and therefore samples sintered at high temperatures have greater resistance to impact.

The values obtained for the entalladas samples are more homogeneous. This fact has also proven during the study of the parameter of the laser power, this indicates that the entalla despite the difference of the value of the work temperature favors that regardless of the results will be minimal.

The values obtained for the entalladas samples are more homogeneous. This fact has also proven during the study of the parameter of the laser power, this indicates that the entalla despite the difference of the value of the work temperature favors that regardless of the results will be minimal.

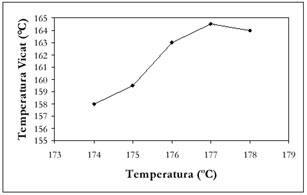

Vicat softening temperature

The results of temperature Vicat for polyamide samples sintered to different working temperatures are shown in Figure 6. It notes that to increase the value of the temperature to which have sintering samples too it the Vicat softening temperature, i.e. the strength of the material under load is increased.

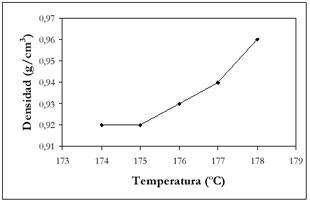

Density

Shows a significant increase the temperature of work (Figure 7), in the density of the material to the increase because that material has compacted more during the process of sintering. For lower temperatures, 174 and 175 ° C, the material has a density of 0.92 g/cm3. With higher working temperature: 178 º C, has obtained a value of 0.96 g/cm3, similar to the provided by the trading house for this polyamide (0.97 g/cm3).

Therefore, based on the obtained results shows that with a 177 ° C working temperature, obtained good mechanical properties in the sinterizadas pieces of polyamide. With this temperature value of working together with the value of the laser power selected in the study included in the previous issue (12 W) have achieved good mechanical properties within the limits of the SLS and the material used equipment.

Therefore, based on the obtained results shows that with a 177 ° C working temperature, obtained good mechanical properties in the sinterizadas pieces of polyamide. With this temperature value of working together with the value of the laser power selected in the study included in the previous issue (12 W) have achieved good mechanical properties within the limits of the SLS and the material used equipment.

Figure 6. The temperature variation of Vicat softening depending on the temperature of work.

Figure 7. Variation of the density depending on the temperature of work.

Related Companies or Entities

AIJU Instituto tecnológico de producto Infantil y ocio