Husky makes things clear in taponería

September 26, 2008

Already in the last edition of the K fair in Dusseldorf, almost a year ago, makers of Husky emphasized special improvements applied to blocks injection systems. "We are working on the proven platform for Husky for the manufacture of caps incorporating improvements" then said Mark Fitzpatrick, head of the area of business blocks in Husky. "The new drive of high production offers higher rates of plasticizing, while it provides optimum quality of the mass melted due to a new spindle designed expressly for plastics that are commonly used in taponería".

Has among its clients companies of renown, such as Bericap, director of Engineering (Bericap North America) is of the view that "Husky is constantly working to improve its technology to provide the system to produce faster Stoppers in the world." "By working together with customers, like us, they are more prepared to improve their product."

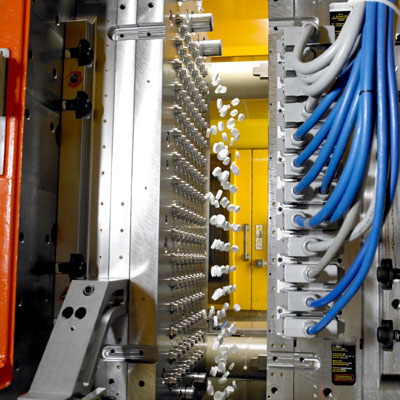

Elocap, manufacturer of corks, attended Husky when he wanted to improve the quality of the closures and production capacity. He acquired several injectors Hylectic and molds of 128 cavities with hot House. It works with cycles of 3.6 seconds and each of their systems produces 2,100 caps per minute or three million pieces per day.

Husky offers a comprehensive solution, which includes hot camera systems, controllers of temperature Altanium and the Hylectic injection molding machines.

Altanium drivers are designed to control the temperature in the most precise way possible through distributed control and 'Active Reasoning Technology (ART) technology. Husky acquired this business unit of Moldflow in June 2007.

All components of the production system are designed to work together with others. They provide complete control of the flow of the mass, which translates into an excellent quality of the pieces, even with casts of many cavities.

The most recent improvements that Husky has added to its production of Stoppers lines improve the quality of the piece and also broaden the range of possible applications, such as blocks of single-piece and type 'flip-top'.

A notable improvement is the new drive for high productions, which maintains the temperature control of mass fused with much higher rates of plasticizing.

New spindle also deserves to be highlighted. It has been designed especially for Cork, ensures quality and consistency of the melt, avoids the excesses of temperature or the tendency of the material to overheat and ensures the consistency of cavity on cavity. The system includes the hot channel Ultra 350 systems, which improve the quality of the piece in complex as is the case with the caps 'flip-top' access applications and that they have been designed for the compact production and many cavities of small parts. It offers a direct entry into areas of difficult access with distances between very small nozzles, even 18 mm. They are systems for production up to 30 grams per second.

Hot camera distributors provide a uniform heat distribution and ensure a uniform temperature.