This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Actronic en Equiplast 2008Actronic in Equiplast 2008

Pavilion 4 Stand B224

Actronic, society of services for marketing and technical assistance of machines injection and peripheral to the Transformadora industry of raw plastic, takes part in Equiplast and its new features include temperature controller of SSIS, extrusion machines of double spindle for profiles pipe of PVC and its revolving base by numerical control of AG.

Base for numeric control of AGP

Pioneers in systems multi-inyección, AGP development presents his base by numerical control, with an accuracy of 1 hundredth of a degree twist.

Control allows an optimized programming thanks to the calculation of inertia of movement, so it automatically positive and negative acceleration to get the higher speed of rotation according to the mass to move.

Anchoring to the cavity axis allows the passage of up to 12 circuits regulation, as well as the passage of electrical power and thermocouple, thanks to a specially designed rotating racord to this effect.

The Rotary Foundation can be installed on any machine to inject up to a height of 1,800 tonnes.

Range Select, fuel electric transfer of 75 to 400 tons

The injectors in the Select range of 75 to 400 tons is fully electric.

It consists of a control Dixit II, the same man-machine than on a hydraulic interface.

It allows the display of the position of all its components, not the bearings that trigger them.

Integrates planetary, greater strength and precision bearings (5 to 50 µm / 300 mm).

The strength of support of the Group equivalent to a hydraulic machine nozzle.

The back pressure and injection pressure are controlled by a cell of burden that measures applied pressure directly on the spindle.

Available fully electric multimateria versions.

Extrusion machines Jwell-Eurinter

Actronic exposes extrusion machines of double spindle for profiles and PVC pipe. They are machines imported by Eurinter, brand that offers the guarantee of the experience in the plastics sector. The 65/132 and 55/110 models are presented. Manufactured with European standards, groups of plasticizing bi-metálico treatment with PLC Siemens, the reference brand in Automation control. We offer full lines of extrusion of profiles, pipeline and all matters relating to the vast world of extrusion.

Regulation of temperature from SSIS

They presented the new model of the 8 series modular temperature controller. Each module comprises two zones and its technical characteristics include, the compatibility of thermocouple type J or K, the auto-Adaptive regulation or adjustable IP, ramp and slope of adjustable boot cut of waveform in time and temperature, visualization of effective intensity in load in amperes, display of the power applied and installed, communication by RS485 Protocol Euromap 17 or 66 (Can Bus). They include assurances that incorporates, alarm of high and low temperature (with a margin of error of 0.5%), rupture of thermocouple, investment of thermocouple, rupture of cargo, alarm alarm protection envelope tensions, GRB 20A fuse and safety thermostat.

This model is available from 2 to 16 areas, with a maximum power of 4600W by area.

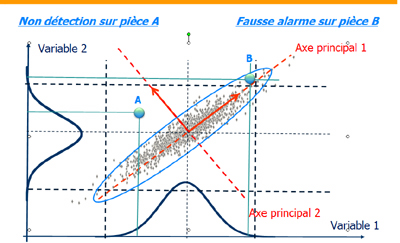

PSP, control and assistance of the injection process

The creation of this system has been based with the intention that any piece that comes out of machine is of the required quality. It works on the basis of a sequential injection equipment, with a machine data acquisition in real time and a computer program that manages the data acquired during the process, with an intuitive software that offers excellent opportunities. It's a great team of sequential injection, a data acquisition system and statistical control of production software.

Points to note this control are as follows:

-Sequential injection controlled by sensors located inside the mould.

-We pilot the switching of the press point.

-Easy installation for the data acquisition system.

-Acquisition of the phases dynamic and static injection, as well as the phase of dosage.

-Automatic detection of failures of quality with data extracted both the machine and mold.

-Automatic recognition of the mold.

-System of traceability of the piece.

Termorreguladores for water and oil SSIS

This time it introduces its new range of mould temperature control by fluids SSIS-Parmilleux, with a few ranges of temperature ranging from 20 to 350 °, with construction, reliable and robust, tailored to the needs of our customers. We highlight the work in depression, mould may have leakage. Regulation with PID Adaptive auto, low heating density, which gives us an exceptional longevity of elements heaters, storage expansion, safety valves for on pressure.

Related Companies or Entities

Equiplast, Expoquimia, Eurosurfas. Fira de Barcelona

Siemens, S.A. - Smart Infrastructure