This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at Los robots proporcionan ayuda inteligente

Bocholt, Bayer and Engel Siemens collaborate on a cover of phone

Robots provide an intelligent help

Walter Aumayr

Director of the factory Engel Automatisierungstechnik15/10/2002

Director of the factory Engel Automatisierungstechnik15/10/2002

Whether it's work of extraction and deposit in the injection as supply stations of retouching, "the man with the machine" is ceasing to be so common. Automating manufacturing processes is not intended as a priority save expensive staff costs but to ensure the high quality of the processes and product, currently indispensable. Handling devices and robots have become essential for companies that are dedicated to molding by injection.

Manipulators and robots work to an exact and precise rhythm in their repetition, and this very quickly and the 24 hours of the day. Many innovative, intelligent and complicated solutions would not be feasible without Automation, such as the following example shows.

An excellent example in a case of phone

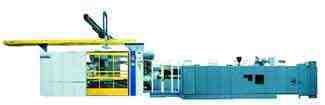

Fig 1: the robot's high-speed ERS (1) integrated into the injection (Victory Engel 200/120) and the additional linear robot ERC 23/1-E machine (2) work at a pace synchronized each other: the LRA is responsible for quickly put the plastic into the mold and take the castings; the ERC prepares new plastics and organizes the distribution of parts.

To manufacture parts of thin walls decorated with plastic casing, ready to assemble for a wireless phone, inject without watering special plastics with an ABS/PC in an Engel 200/120 Victory mixture without columns in a hot channel 1 + 1 mould cavities. To ensure profitability, the cycle time should be extremely short: preferably less than 10 seconds, according to requirement. Without Automation it would be unthinkable. In this production cell used two linear robots (Fig. 1): a manipulator for high-speed (Engel ERS) integrated in the fuel transfer, with minimum mass moved and highly dynamic servomotors can accelerate up to 150 m/s2, and a standard linear robot (Engel ERC 231-E). Another component of automation is a Trayserver (trays Server) (ETS), integrated as a buffer memory in parts. Result: the time of this production cell cycle is only 9 s.

The unity of closure without columns of the machine fuel transfer, of free access, facilitates lateral integration of the robot's high-speed (ERS) in the cell production, a great advantage to achieve cycle times shorter and, thereforemaximize productivity. Thanks to the high speed robot, the placement of the plastic into the mold and the taking of the finished pieces are held in way extremely fast. So take a plastic previously focused on preparation station and goes with it to the position of waiting in front of the still closed mold. To open it enters the mold and put the plastic in the exact into the mold cavity position. At the same time taken with its dual-head of desk, located on the side of the nozzle, the pieces of the casing (top decorated with plastic and bottom without decoration) and extracted them from the mold. The linear robot (ERC) manages the distribution of the pieces in the corresponding trays and the preparation and the prior focus of new plastics. Only through this Division of labour and communication interlined between parts of the installation are created in a time extremely short two pieces of plastic which can be the Assembly directly from the cell of production, without any extra work.

Thanks to this joint development of Siemens Bocholt as a manufacturer of the pìezas, Bayer as a supplier of material (also of the plastic decoration) and Engel as the installation Builder, has gone from an industrial manufacturing of large series of covers of telephone of plastic injected across its surface in the technique of thin-walled to a profitable maturity in the series. The installation is also a sample of the possibilities of modern technology IMD (IMD: In Mould Decoration = mold decoration). The example of production documents at the same time that often the combination of the technique of manipulation and the fuel transfer becomes the key to the profitability of the transformation of plastics molding technique by injection. Thus this application requires a high stiffness of the closure system, fast movements of the machine and high speeds of injection machine. Equipped with the corresponding modules, the machine for molding by injection of modular construction Engel Victory meet these conditions for thin-walled with inserts of plastic injection-moulding.

The installation Builder must perform this symbiosis of machine for molding by injection and handler. In order to make available to the company of injection technique of most appropriate installation to its task of transformation, Engel develops and also builds, in addition to machines for moulding by injection, the appropriate automation, complete systems from the single manipulator to the complicated cell manufacturing with specific seasons of further development of the product-including the EC declaration of conformity.

The unity of closure without columns of the machine fuel transfer, of free access, facilitates lateral integration of the robot's high-speed (ERS) in the cell production, a great advantage to achieve cycle times shorter and, thereforemaximize productivity. Thanks to the high speed robot, the placement of the plastic into the mold and the taking of the finished pieces are held in way extremely fast. So take a plastic previously focused on preparation station and goes with it to the position of waiting in front of the still closed mold. To open it enters the mold and put the plastic in the exact into the mold cavity position. At the same time taken with its dual-head of desk, located on the side of the nozzle, the pieces of the casing (top decorated with plastic and bottom without decoration) and extracted them from the mold. The linear robot (ERC) manages the distribution of the pieces in the corresponding trays and the preparation and the prior focus of new plastics. Only through this Division of labour and communication interlined between parts of the installation are created in a time extremely short two pieces of plastic which can be the Assembly directly from the cell of production, without any extra work.

Thanks to this joint development of Siemens Bocholt as a manufacturer of the pìezas, Bayer as a supplier of material (also of the plastic decoration) and Engel as the installation Builder, has gone from an industrial manufacturing of large series of covers of telephone of plastic injected across its surface in the technique of thin-walled to a profitable maturity in the series. The installation is also a sample of the possibilities of modern technology IMD (IMD: In Mould Decoration = mold decoration). The example of production documents at the same time that often the combination of the technique of manipulation and the fuel transfer becomes the key to the profitability of the transformation of plastics molding technique by injection. Thus this application requires a high stiffness of the closure system, fast movements of the machine and high speeds of injection machine. Equipped with the corresponding modules, the machine for molding by injection of modular construction Engel Victory meet these conditions for thin-walled with inserts of plastic injection-moulding.

The installation Builder must perform this symbiosis of machine for molding by injection and handler. In order to make available to the company of injection technique of most appropriate installation to its task of transformation, Engel develops and also builds, in addition to machines for moulding by injection, the appropriate automation, complete systems from the single manipulator to the complicated cell manufacturing with specific seasons of further development of the product-including the EC declaration of conformity.

Fig 2: ERC 23/E, ERC 63/E and ERC 94/E, the three basic sizes of the new series of linear robots Engel, with constructive characteristics, cover completely outside forces closure of current injection machines.

Handling of avanzadísima technology

Each manipulator system, whether is an extractor of lava flows from a single axis as a complicated ERC (Engel Roboter Controlled = controlled robot Engel), is today modularizado as a result to the last detail. From this modular construction suitable for the client automation solution arises from quickly and flexibly.

In theory, these components can be individually combined to form more than 10 millions of variants.

The modular construction has been consistently in the now current fifth generation of robots of Engel, the so-called series E (Fig. 2). The smaller size (ERC 23) standard is designed for machines with forces closure of 400 to 6,000 kN, the median (ERC 63) for quantities of force closure of 2,500 to 18,000 kN and the large version (ERC 94) in this family automates machines for moulding by injection with forces closure of 13,000 to 55,000 kN (Fig. 3). Series E, robots Engel covers thus the range of machines for moulding injection used in the market.

The modular construction of the new series platform and brings many advantages to the industrial transformer and increased performance for less money in comparison with the previous series:

-higher speeds and accelerations in the standard implementation, - various power levels, selectable in digital control systems, - longer maintenance intervals and pleasant service (thanks to the permanent lubrication of the drives by zipper, to the use of linear guidance systems that require little maintenance)(, to the use of pluggable end switches, etc.), - digital control the vacuum of the suction cups (with indicator element and management), - extension of the number of optional additional modules, and what is not less important-lower price compared to the previous series (according to equipment)(, a 10-15 per cent).

In theory, these components can be individually combined to form more than 10 millions of variants.

The modular construction has been consistently in the now current fifth generation of robots of Engel, the so-called series E (Fig. 2). The smaller size (ERC 23) standard is designed for machines with forces closure of 400 to 6,000 kN, the median (ERC 63) for quantities of force closure of 2,500 to 18,000 kN and the large version (ERC 94) in this family automates machines for moulding by injection with forces closure of 13,000 to 55,000 kN (Fig. 3). Series E, robots Engel covers thus the range of machines for moulding injection used in the market.

The modular construction of the new series platform and brings many advantages to the industrial transformer and increased performance for less money in comparison with the previous series:

-higher speeds and accelerations in the standard implementation, - various power levels, selectable in digital control systems, - longer maintenance intervals and pleasant service (thanks to the permanent lubrication of the drives by zipper, to the use of linear guidance systems that require little maintenance)(, to the use of pluggable end switches, etc.), - digital control the vacuum of the suction cups (with indicator element and management), - extension of the number of optional additional modules, and what is not less important-lower price compared to the previous series (according to equipment)(, a 10-15 per cent).

Fig 3: The larger (ERC 94/144-E) in a large machine (Engel Duo 75050/3550): in order to minimize the height of the installation, the axis and (vertical axis) of the ERC is equipped as a tandem axle (this also applies to smaller sizes)(, ERC-63 and ERC-23).

Photo: Engel

Remote control robot - intelligence of automation

The integration of systems of command of the injection and the robot machine (the so called command integrated, used in the complete systems Engel) offers advantages to the user, because it should only deal with "a" System. With the introduction of the new series of robots developed also this "brain" of the technique of handling, occupy a Prime place since the beginning of the technique of automation Engel, 20 years ago. The achieved improvements are, among others:

-a more rapid synchronization of the movements of the robot and machine - without additional hardware - via an internal bus connection of the systems of command, - new features for easier programming and management mode menu and teach-in-built-in security functions expanded and much more. Only focuses on the new role of system Softservo (Fig. 4), with which the strength of each axis is adapted to the respective situation. This is important for example in work placement and takes controlled by force or in the process of sliding.

With the remote control robot stand - alone also available, all Engel robots can also be used in all machines other than Engel and can communicate with them. This command has a very powerful RISC processor like the integrated version (common management of the command of the machine and controller of the robot through the screen of the machine), and communicates with the digital system with sensors and actors of the robot via a CAN bus and drive.

-a more rapid synchronization of the movements of the robot and machine - without additional hardware - via an internal bus connection of the systems of command, - new features for easier programming and management mode menu and teach-in-built-in security functions expanded and much more. Only focuses on the new role of system Softservo (Fig. 4), with which the strength of each axis is adapted to the respective situation. This is important for example in work placement and takes controlled by force or in the process of sliding.

With the remote control robot stand - alone also available, all Engel robots can also be used in all machines other than Engel and can communicate with them. This command has a very powerful RISC processor like the integrated version (common management of the command of the machine and controller of the robot through the screen of the machine), and communicates with the digital system with sensors and actors of the robot via a CAN bus and drive.

The application decides

Depending on application, with the ERC series of Engel takes time is can minimize 0.7 s and total cycle times until about 4 s. For such aircraft in series, these are already values very good performance, but for cases of application special (normally in the injection molding of thin-walled or for the manufacture of pieces of packaging), these times are still too long. For those "applications at high speed" is used high speed robot ERS, mentioned at the beginning.

But not all applications require High end performance. To take the injected parts and place them on a conveyor belt, the manipulators of the ER-HLi series offer an economic automation solution integrated, especially with machines without columns Engel in outside forces closure of 200 to 6,000 kN. This compact device of decision-making can be mounted alternatively in the fixed portamoldes plate or on the mobile phone. The pieces are deposited on the conveyor belt built into the grid for the protection of the machine. The area of the mold is well accessible, since the conveyor belt can move if necessary.

Full service of the technique of automation Engel program is completed through a comprehensive kit. Head of reception of the robot according to the geometry of the workpiece can be individually configured with the same. (Fig. 5).

But not all applications require High end performance. To take the injected parts and place them on a conveyor belt, the manipulators of the ER-HLi series offer an economic automation solution integrated, especially with machines without columns Engel in outside forces closure of 200 to 6,000 kN. This compact device of decision-making can be mounted alternatively in the fixed portamoldes plate or on the mobile phone. The pieces are deposited on the conveyor belt built into the grid for the protection of the machine. The area of the mold is well accessible, since the conveyor belt can move if necessary.

Full service of the technique of automation Engel program is completed through a comprehensive kit. Head of reception of the robot according to the geometry of the workpiece can be individually configured with the same. (Fig. 5).

Fig. 4: The new role of the "softservo" system allows a sensitive Guide to each axis, adapted to the respective task.

Photo: Engel

Fig. 5: Head of reception, especially equipped for making molded technical parts.

Photo: Engel

For more information:

Related Companies or Entities

Roegele, S.A.

Siemens, S.A. - Smart Infrastructure