Kennamental proposes a simple and precise machining

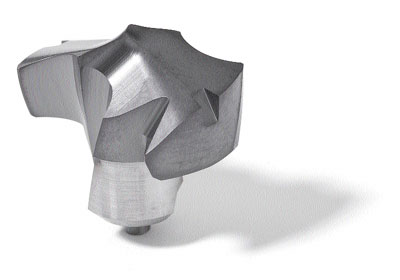

One of the novelties presented at the fair was the drill bit double Tip 2 x 2 of Kennametal, who has developed an innovative concept for the tools of drilling for the first time combining the implementation and the performance characteristics of the drills integrals of hard metal with the commercial advantages of modular tools to drill holes of less 8.5 mm. The drill bit 2 x 2 has parameters of performance similar to the range HP integral hard metal drill bits are. This allows to achieve speeds of Court of 150 to 200 m/min in applications of steel, which exceeds the standards of the market for such tools.

Compared to the conventional integral hard metal drills, the life of the drill bit 2 x 2 tool is usually 4 times because the drill bit has two points of court rather than one, which is the traditional.

B222HP, a series of drill bit long hard metal integral for cooling and dry machining

The new integral hard metal B222HP of Kennametal drill is designed specifically for applications with coolant and dry machining to depths of drilling of 5 times the diameter. The drill is designed for applications in steel and foundries and complements the already successful range of drills B221HP.

The drill bit has the geometry of patented HP tip of Kennametal allowing high rate of penetration and higher productivity. You can get productivity gains of up more than 30 per cent, increasing production and reducing manufacturing costs. The drill is supplied on the KC7315 quality of Kennametal has a soft TiAIN coating multi-layer which reduces the regrowth of edges and improves the flow of wood chips. It also ensures a long life of predictable tool even in the most demanding operations. Such parameters of operation are only normally associated with drill bits with inner cooling.

The B27-Z-HPG bits of hard metal for deep drilling

Quality KC7425, based on a substrate of quality sub-micras, offers the durability and the tenacity to applications of deep drilling in steel as well as applications of cast iron and ductile cast iron crankshafts, connecting rods and cylinder heads and blocks of the automotive industry.

Drill bit for polymers reinforced with carbon (CFRP)

With it, the company offers a tool that enables a process of court without burrs or peeling in the life of the tool, while reducing costs at the same time.

The drill is a real alternative to the expensive PCD bits, especially for CFRP (carbon fiber-reinforced polymer) materials drilled on CNC machines. Compared to the PCD bits, SPF drill gets average tool life twice before the delaminaciones to appear on the part of the drill bit output.

New geometry and quality KenTIP for stainless steel

With the new geometry KenTIP-HPL (M), Kennametal presents a unique innovation for drilling stainless austenitic steels which in combination with the new KC7320 quality, guarantees the maximum process reliability. The new geometry also reduces noise levels to the machining of stainless steel and is available from 8 to 20.99 mm.

The new chips KenTIP-HPL (M) are adapted to the body of tool KenTIP. Performance tool is at least equal and often exceeds, the drill bits of integral hard metal both productivity and cost of tool.

Dodeka, new program of milling planning

With Dodeka, Kennametal offers a new program of milling planning that it is unique in the world and produces a 30 percent increased productivity - with identical power consumption of the spindle of milling-, compared with products available so far in the market. Numerous field installations of customers and the immediate subsequent orders tests confirm this promising innovation. Dodeka is a program of milling to reduce the costs of production in several ways.

New geometry and quality KSEM for stainless steel

Kennametal presents an innovation unique to the field of boring with the new plates KSEM-HPL (M). A completely new geometry for the drill of integral hard metal's patented modular KSEM in combination with the quality also new KC7320 guarantees the maximum safety of process for drilling austenitic stainless steels, and at the same time, a machining low noise level. With the cutting parameters which often allow double productivity, get lives of tool much higher than the comparable integral hard metal tools common or HSS.