Delteco, S.A. in the EMO 2007

Hermle AG

Hermle AG, manufacturer of machines represented in Spain by Delteco, sells all its products with the possibility of automation. At Emo Hannover 2007, you can visit your (C36) stand in Hall 12. With different pallet changing solutions, Hermle opens new horizons in the preparation in parallel at the time of production in their dynamic 3, 4 and 5 axis machines.

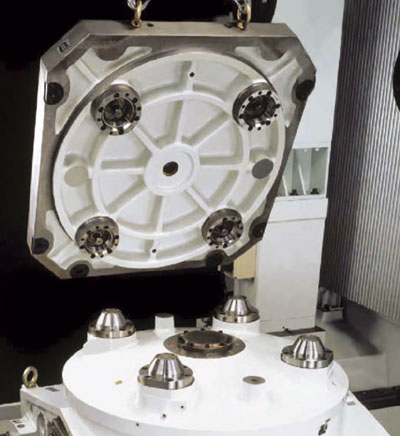

Pallet changer is adapted to the machine by the front and can be supplied with a warehouse with a capacity for four additional pallets, or without it. Adding the changer, a 5-axis machine is transformed into a centre of fully automated machining, which still allows access to the workspace to perform manual work, such as the configuration or the feeding of individual pieces.

The main advantage of this system is that it allows simultaneously manipulate three pallets, with a consequent reduction of the setup time. Now, if you select the changer of pallets with an additional store for 4 pallets, pallet number increases to 7, which allows at the same time that the double clamp also load pallets in the store, or to withdraw them from the store for machining. The software of management of the pallet is integrated into the machine control system, and functions as to emergency key confirmation and controls for automatic attachment of the piece are integrated into the dashboard and are fully accessible to the operator.

The day-to-day with a system of this type is easier thanks to a series of intelligent details, such as mobile upper deck cargo crane, expulsion, fitted with a drawer for collection of shavings and refrigerated tube with lubricant, or the station of configuration with manual rotation.

By way of example, pallet changer model PW 160 only required 3.5 square meters, more 1 square meter additional for 4 additional pallet store. Thus, the space required for 7 pallets (with maximum dimensions of pallets of 400 x 400 / 500 mm in diameter) is reduced to 4.5 square meters.

The modular structure of the changer of pallets that uses the proven technology of mineral casting prevents the transmission of vibration during transportation of the piece to the machine of mechanization. Pallet changer is built in a single unit, transported piece and is installed to the machine.

Special mention to the subject of the pallet system. Precise machining of pieces depends on the exact positioning of pallet of parts. The subject and positioning system guides the pallet of pieces in all the degrees of freedom for a functioning and position accurate and offers a safe positioning for the process.

Contrary to other fastening systems, with the system of subject of pallets of Hermle, the essential problem areas are avoided selectively and it is complemented with own developments.

In automated production systems and the complex machining operations with frequent changes, then becomes necessary to have a greater number of tools. For this reason, Hermle offers its customers three stores additional, depending on the number of tools required. Standard warehouses can be complemented by additional stores of 43, 87 or 157 posts tools.

Quaser

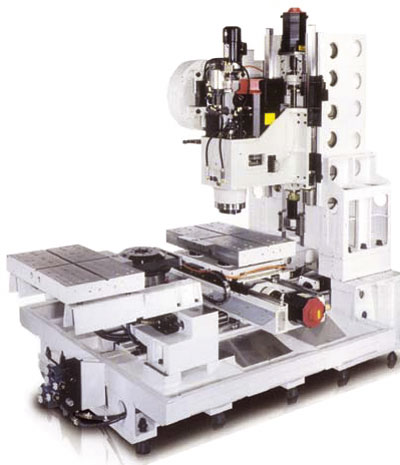

Quaser company, also represented in Spain by Delteco, exposes its horizontal HX 805 AHT machining, with 800 mm pallet Center at Emo 2007 It is equipped with control Fanuc machine 18iM-B, which incorporates the concept 2 + 2 and rigid frame structure in order to run a high-speed performance and cut heavy. In addition, this model, which has a capacity of 1,200 mm x 1,100 mm x 1,500 kg, incorporates transmission of the axes directly with engine in axis X 7 kW, in axle and 6 kW, and Z axis, 7 kW. It also has type NB50 spindle of high torque (955 Nm), storage of tools up to 60, with a maximum length of 600 mm and a weight of 25 kg tool; a tank of cooling of 1,200 l (cooling through spindle, 20 bar, and peripheral spindle, 4 bar cooling nozzles).

In the company's stand, visitors also will see closely the model MV-154APC/P, a high speed vertical machining centre, equipped with CNC Fanuc 18 iMB and automatic changer of pallets for series production. Presents a single-piece and base structure of rigid frame for a speed of 40 m/min, with 0.5 G of acceleration/deceleration (5 / 5 / 5 m/s_). This machine, versatile, reliable and accurate, has a main spindle of high performance, a structure cast in all its components, front stainless steel, and cars and column that provide a high rigidity associated with a large capacity boot of chip in volumetric terms.