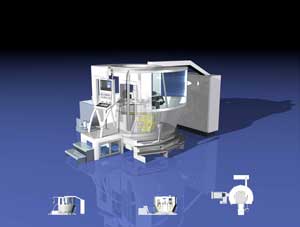

Multicentre D4 of the Everest Series, seen in detail

The multicentre D4 - explains Michele Andreola, general manager of Dauma - is son of the Everest installation of ten seasons - nine of work and one of automatic loading/unloading already submitted by Dauma Bimu in 2004. But the new machine is not limited to meet the technological experiences developed in previous installations, but shows three major characteristics for a work machine:

- Speed and accuracy

- Flexibility

- Speed of change of model to model to be made (set-up of the machine)

Therefore the D4 multicentre is an installation that you want to synthesize the requirements expressed during these years by the same clientele of Dauma and investigations in the various sectors, such as the automobile, the hydraulic, tire, etc.

The new Everest has remained the fundamental characteristics of the original machine, but is very close to the daily demands of the customers with regard to technology, functionality and the technical.

"We are sure - says Andreola - of started a new concept for the work of mechanical components in 2004." "The development of this multicentre Everest Series is a great help for those companies who work directly or on behalf of third parties in the production of mechanical parts used in the most different sectors".

The advantages of the engine torque

Dauma experience in the use of the engine has already matured much and it is possible to confirm that, by all of the advantages resulting from it, it is a very good solution in the displacement of large rotary tablesYou can facilitate the project of the system of table - movement piece, does not wear away and does not need maintenance, is accurate, reliable and allows for short periods of time of transfer of the satellites chucks of an operational area to the other.

Thanks to the torque engine also has been optimizing the dimensions of the table to make a wide space between a workstation and the other. Therefore the operator can climb on the machine, easily reach work areas where has a broad space of displacement for the substitution of templates chucks (automatic performance of the headset) for changing the production and enjoy ample spaces for scheduled maintenance work.

On the turntable in continuous carrier, furniture modules swivel units are housed (speed Max. 1200 rev./min - 4 ° axis of work) customizable depending on the type of pieces to be buckles.

The mirror of the table is also provided, as the rest of the installation, open spaces to perform customizations with ease of implementation and facilitating project times. All customizations are installable with quick connection systems. With a multiple series of appropriate templates distributed on the table, it is possible to obtain the maximum speed of conversion, from a series to the other with the simple programming in the control panel depending on the type of piece to be working.

Dauma has developed the fifth axis CNC satellite units to give maximum flexibility to the work of the pieces. with its own patent proposes the possibility of integrating other axis for rotation of the piece in both axes of movement of the same order.

In the center of the table are the units of distribution for the command and power fluid that feed the work areas.

Three three-axis workstations

The base - workstation interface has been made on a surface worked with a machine tool, rectified to maintain the necessary tolerances and displaced on caged roller guides. Movements are handled by motor without brushes that trigger a ground ball spindles.

Each workstation provides as standard an electromandril (passage of the hole for Jet of high pressure tool) combined with a warehouse with a change of tools from several positions, but it is customizable according to requirements, for example applying a few units tool of revolver.

Another feature is the displacement of the former doors, which open a wide window of access to all the machinery and allow the operator to enter and walk along the machine perimeter. The positions of connection of the remote control panel, located externally, allow the operator to engage in the operations of tuning of the installation in full freedom.

All the tubes and cables in distribution of hydraulic and electric services meet in spaces in support above, isolating them from the work area to avoid contamination with the coolant. Connect with the work units through downs located and covered in flexible sheaths right up to the entrance of the same unit area.

Electronic group is integrated: the motors, drives, the CNC are supplied as standard brand Siemens, Fanuc, and others upon request.

A new concept of production

The strong of the multicentre series EVEREST model 4 d points

- Productivity: the user can perform all work licensed in a traditional workplace at each station, but the availability of 3 units of work and 3 cores working simultaneously allows triple its benefits and therefore also their productivity.

- Flexibility: 3 workstations can be used independently from each other, are controlled from the same position, are programmed one at a time to optimize the level of the cycle. The user also has a high number of tools (up to 40), each season has the possibility and balancing the cycle of work in 3 seasons for the best results. Thanks to the possibility of placing on the table a series of templates for different types of parts fixing you can find maximum flexibility, the maximum speed of re-equipment and work, from a number to the other with the simple programming of CNC depending on the type of piece to be working. All customizations are installable with hitch systems fast.

- Speed and accuracy: thanks to the availability of a continuous rotary table with engine torque. The election, as well as the draft of the system of table - movement piece, make simple does not wear, you do not need maintenance, it allows to obtain high precision, high reliability, reduced chip to chip time.

- Versatility of work: thanks to the satellite chucks with 4 ° and 5 ° axis CNC control and the series of templates in the table.

- Freedom of configuration: thanks to the availability of vertical or horizontal labour units, characterised by modularity and a high standardization.

- Full accessibility and operation ergonomics: spacious achievable facilitate access for the operator and the implementation of the work of implementation, maintenance, rapid re-equipment for the change of production. The positions of connection of the remote control panel, located externally, allow the operator to engage in the operations of implementation to installation in full freedom and therefore also in front of the station involved, without the link to work in the front part where CNC control will be positioned.

- Field of work: standard cube of 250 mm (incrementing order) side.