Robotizar injection workshop

ABB

The new driver of industrial robot is oriented directly to the user, with a system that simplifies the entire process, from the preparation of the installation, through its configuration and implementation, to your service. A key element of its ease of use for the user lies in the innovative device in world of Robotics for dialogue "user-controlador·, of the programming unit touch that instead of physical keys, bases its operation on its touchscreen."

The modular concept also means that each system alone is only a profitable investment. It has been designed to match the needs of the user, at the time that has potential for expansion to cover future needs. It is a solution that allows to increase profitability throughout the useful life of the installation.

The modularity of the IRC5 is a step forward in the control of robot with a logical division of duties in: System drive and process control. Each module is housed in their own wardrobe and they have the same base.

Another interesting model. Robust and fast, the IRB 1600 robot allows movements backwards in response to important market demands. Designed to be an optimal robot in terms of cost, the IRB 1600 is intended to make it the most suitable in applications of arc welding and paliaciones of casting Assembly or packaging.

The repeatability of the position (± 0.05 mm) and a good trajectory accuracy provide a consistent quality in your application.

Loading options useful are 5-7 kg (up to 10 kg with the wrist position down).

Caufar

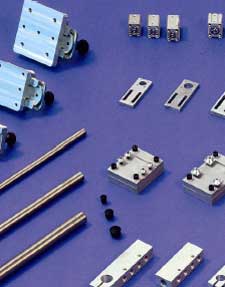

The new system, developed in collaboration with major construction companies of robots, allows quickly hands of grip, choosing from a variety of application-ready solutions.

All components are simply assembled with the help of few tools, and can be reused several times.

Caufar sells also a wide range of robot for plastic industry applications. Other series include the robots of Cartesian numerical Control (CNC) Tecnomatic, which represent the ultimate expression of automated technology of moulding of thermoplastic materials and are the synthesis of 15 years of experience gained in this sector. The programming free guided (FGP) of which are equipped with all the robots is to make extremely flexible work cycles, without any limit in the complexity and extension of the programming to perform. Programming, however is simple and intuitive, accessible to all.

This series of robots is also made of a structure of highly rigid vertical shaft of light of high-strength alloy steel; that consent to achieve very high speeds combined with a high structural stiffness. All used components are the best available in the market, made by companies of first level. The models in the series are MiniCNC, Medium CNC; Large CNC, Extralarge CNC, CNC XXL and Mega CNC, depending on its size, working, minimum times of cycle and application to injectors.

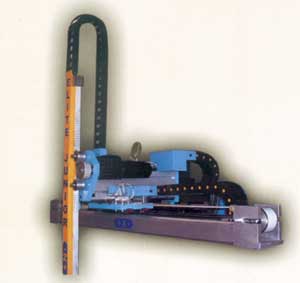

The Mini-CNC robot incorporates a technology for the automation of the processes of molding by injection. It's a Cartesian machine with numerical Control (CNC), endowed with programming free guided (FGP) that allows to work cycles without limitations of great complexity or duration.

Robots are also made in highly rigid steel with vertical axis of high strength light alloy: This allows to achieve very high speeds combined with a high structural stiffness.

Brushless servomotors are high power on all axes, the movements of the axes are made on prismatic guides rectified in the same way that skates are mounted on ball bearings. Speed gearboxes are of type epicyclic and are considerably overblown.

Equiper

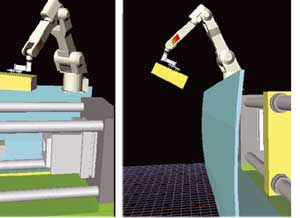

Applications of the robot are the removal of pieces and their positioning, peripheral equipment (connection with conveyor, spray, cutter, sensor or supplementary machine, getting an automated system) and review, either, rejection, inspection, quality review and counter parts.

Series SB are several models of 3-axis servo motor CNC robots. Its features include free programming of control functions, the standard programming of multifunctions, position speed and adjustable time during the operating cycle and the system and parameters of programming that can be memorized for large productions.

The SC series consists of several models of 3-axis robots with vertical telescopic arm. For its part, the ST series of oscillating arm robots allow an easy to use in a design only, is of high quality and low-maintenance, requires in addition a simple installation and the cycle time is characterized by the speedas well as depreciation.

Robot Inser

Applications developed by this Basque company, include the automation of different industrial sectors, including plastics. In particular, the loading and unloading of machines injection, the Assembly and all types of handling parts.

Robots for handling and loading and unloading of the Kawasaki brand - distributed exclusively at Spain and Portugal by the company Inser Robotics - take up very little space, have a high precision and flexibility, are very simple management and are depreciated in record time.

Robotics Dumy

They have anthropomorphic robots to insert tags, palletizing and stacking different materials: marble, tiles, drugstore products, accessories.

In addition, manufactured robots commissioned for the application that is needed.

Reis Robotics Spain

The repeatability is between +/-0.1 and +/-0,3 mm depending on the model and have rotating axes or cantilever chairs (except the RL6) in NC and pneumatic version.

Its main advantages are its more robust mechanics; with a life expectancy greater with minimal maintenance; and a greater speed in the axes.

RV16-Laser robots and RV16L-Laser show different characteristics depending on the type of laser used for cutting. Thus, robots for CO2 laser, apply to cut injected plastic or cloth components with sealing of court singing. They are also as application cutting of textiles and plastic foils, drilling and drilling of pieces of plastic with pulse generator or the deburring and cutting of injected parts. They are also used to make the cut of pieces of various materials and reinforced with fibres, and even the cutting of metals.

Robot Sepro

Thanks to Sepro compact numerical rotations, the robot is equipped with a greater adaptability to ensure the unloading of the fuel transfer, especially allowing the multiple positions in the mold or out of the press to adapt to the possible difficulties of the injection of plastics.

Sepro provides in this way from a range of rotation R1 + R2 CNC on their robots for 150 to 4000 t presses

In order to gain in precision and effectiveness, Sepro has developed numerical vacuostatos for schedule and memorize piece collection settings to perform from the command Visual Sepro console.

3-Axis CNC generation IV robots are controlled by the electronic Sepro Visual. Its Electronics is based on the graphic and touch technology. Extremely powerful, Visual Sepro can control up to 8 axes CNC simultaneously.

The "single download" module allows you to create a cycle of simple download through a set of FAQs and a graphic illustration, without knowledge of the programming language. To ensure simplicity, simple download module is voluntarily limited to the following applications: making flows into the mould and parts following a cycle L, simple download with management of two different circuits for a download separate parts, management of a third circuit of pressure for a download separate lava flows.

Three programming modes are characterized by their simplicity, standardization, and its power, with direct sequential programming or learning.

Software technical Tecnocim

Robotmaster has been developed in Canada and works in combination with Mastercam.

Star Automation Spain

Among its range stands out the SP-IVF series of lava flows and small pieces of vertical input, extractor suitable for presses from 30 to 250 tons, which are equipped of a rotating wrist and vacuum generator. With this series you can download not only lava flows but also small molded parts.

Suitable for 25 to 3000 tons, Cartesian robots series presses Gxe/Gxe-s, have 3 axes servo motor for fast repetitive cycles and high precision.

The ixe/ixe series - s, includes robots suitable for 25 to 3000 ton presses. Cartesian robots CNC to servo are Motors digital CA in the three main axes for fast repetitive cycles and high precision.

The ixe-H/Gxe-H series, designed for presses of 30 to 1300 tonnes, is the range that takes up less space. The transverse axis situated longitudinally moves the piece shaped in the same vein, which involves a double saving of space around the press against the Cartesian robot.

Another model of the broad portfolio of the company is the high speed series Zxe, suitable for presses from 100 to 350 tons. This robot is designed for any application of high speed where speed and accuracy are compulsory.

Series TZ-HM, lateral and adequate input for presses from 50 to 350 tons, is a robot for cycles of very high speed (for example, packing of food, IML, DVD, etc.) the approximation to the correct automation is based on the robot's side entrance in the TZ-HM series for faster downloading of castings.

The functions handling robots of the TW-III E series standards are

Technicians of automatons and Robots

Its operation is simple and comfortable: inside a fenced area at the side of the fuel transfer, a robot of six-axis Fanuc S-420F and two contramoldes, where the operator places the inserts from outside the security zone is located. The robot is able to pick up all the inserts at the same time and place them in the cavities of the mold. Also, once the piece is injected, the robot her extracts, short lava flows and the paletiza in a container.

Wittmann Robot System

Thanks to the latest development in technology of microprocessors used in series 6, the size of the control cabinet has been reduced to a minimum to optimize the space give the production plants.

Robot W 6621, 631 W models have a vertical arm built a tube of steel with a thin wall thickness but of high stiffness. This arm is guided by linear bearings of high load, to allow maximum speeds- and -pinion engine-powered. A group of wrist low profile is used for a race of minimum aperture of mold.

The model of robot W 632 in standard account with a vertical arm in steel tube with a thin wall thickness of very rigid and linear guides with high load bearing. (For payloads of up to 20 kg).

The model of robot W 623 and great starting with the model W 633 robots are equipped in standard with the vertical telescopic arm patentad. The main is powered and guided by rack and pinion. a belt activates the front arm at double speed providing advantages such as: minimum speed of the hand of apprehension and short times of input/output and vertical races long for palletising.

Wittmann robot controller is equipped with color graphics screens which allows an instruction and a more user-friendly than it ever had sudo so far. The operator only outlines the sequence on the screen and adjusts the additional functions under a graphical environment of easy to use to create - step by step - the final programme of the robot. The advantages are: time of very short learning for operators and an increase in safety during the programming.