EuroMold maintains its strength

The show, especially in reference to the exhibition area and the internationality of exhibitors, has grown again, after a slight decline in the number of exhibitors in the previous edition. But in 2005 have broken records: 1,620 exhibitors (117 exhibitors more comparing to the year 2004) 44 countries (5 countries compared with 2004) were presented at 77.131 square meters (increase of 2,310 square meters).

New organization of space

Throughout all of them are unable to verify how moulds manufacturing remains the central axis of the fair, with a good number of moldistas exhibitors. However, the stands with more visits continue to be those related to the construction of prototypes, rapid mould or, as the EOS, companies that already provide the "e-manufacturing", actual parts directly from electronic data.

It is also a fair enough software, is in fact a fair with an unusual combination of the hard, machines and moulds, and so "soft", striking stands to promote their knowledge, their philosophies for the future, in many cases true cases of future, which is already present. This game involves the various design firms attending the fair with impossible car or similar attractions.

Also called attention to the growing presence of exhibitors in countries such as China, Taiwan, Hungary, Singapore, Turkey or Poland, which are represented with a corporate booth.

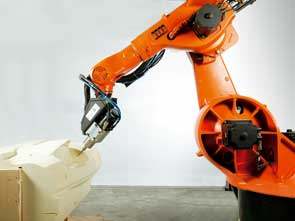

This idea of exposing everything from idea to final production, you can see robots, such as elements integrated into manufacturing cells. KUKA, for example, presented its new solution for milling in Delcam stand because that was programmed with the CAD/CAM Powermill solution.

Resin WaterShed SL of DSM Somos verifies the accuracy of the investment casting requirements

An interesting example was revealed. Greater precision analysis carried out with pieces QuickCast the Office services to the area of Chicago, Express Pattern used resin for Stereolithography Somos Water Shed 11120 to produce models through the process of 'investment casting' (cast iron / traditional lost wax method). The result was a piece that is capable of producing nearly 95 percent of correct masters, a similar figure to the results that are achieved with conventional wax models from molds.

The company produced more than 500 models through QuickCast using WaterShed, in sizes from 1 to 20 inches. Each model was measured numerous times in three dimensions, reaching the 4,300 individual measurements in the finished models. Based on this work, Express Pattern could be verified that more than 98 percent of all measurements were within acceptable tolerances required by manufacturers.

QuickCast refers to a mode of manufacturing hollow in the Stereolithography to create pieces that are subsequently sent to the functions for the process of 'investment casting'. The hollow structure is needed to allow the expansion of the material when heated during the molding process. The percentage of hollow space and solid space is known as the index of gaps. The higher is the rate, the greater the number of successful pieces in the foundry.

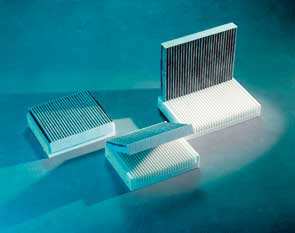

In EOS (represented in Spain by RMS - Rapid Manufacturing Systems) already everything revolves around the "e-manufacturing", the flexible and cost-effective production directly from electronic data. More and more real applications in which the sintered by laser is not used only for prototypes or molds, but also as a manufacturing technology can be found. In this sense, EOS has launched a programme to disseminate the sintered by laser as a method of production of final pieces. The fair saw real parts. For example, a boot of football in which the sole with their cubes is tailored to the player, after analysis of the geometry of his foot and his way of stepping on.

He attended the fair with numerous innovations and examples. Among other things, he participated in the special exhibition for the medical sector Euromold hosted in this Edition, demonstrating the benefits of the sintered by laser in this sector. For the DMLS (direct metal laser sintering) EOS now offers more materials, emphasizing its alloy of cobalt and chromium, highly resistant to temperature and corrosion. It is especially handy in the medical sector, both in equipment and implants, but it has also proved their worth in other sectors.

It has also advanced in the sinter of plastic materials. PrimePart makes it possible to use 40 percent less powder in the production of parts. This polyamide 12 is now available commercially. CarbonMide, a powder of polyamide reinforced with carbon fiber is also available.

He exhibited the machine Eosint M270 and the Eosint P385, in which featured material that was used. In the 270 a cobalt-chromium alloy showed profits in the restoration of teeth.

Next to Euromold, simultaneously and in contiguous blocks, is celebrated the international fair for turned, Torneado and milling technology pieces. 325 exhibitors from 16 countries presented their products and services from all areas of the sector of turned parts, turning and milling technology. Some 18,000 visitors attended the event.

Turntec managed to attract 100 exhibitors new to this edition. Compared with last year demand for foreign exhibitors increased around 3 per cent up to a total of 26 percent. For the first time was with countries exhibiting in: Hong Kong, Ireland, Sweden, South Africa and the United Arab Emirates...

This is the fair of international industry of turned parts, turning and milling technology. This year also, the programme for exhibitors showed the complete supply chain: "from the raw materials to the lathes, tools and accessories to the finished pieces".

Turned parts recorded an increase of 9 percent and a presence of participation of the exhibitors from 51 per cent. Milled parts vendors share rose 13 percent to 18 percent. Other sectors represented are suppliers of raw materials (+ 4.5%), software vendors (+ 4%) and companies that do refinements of metals (+ 3.5%), as well as the manufacturers in the sector of measurement (+ 3%).

Among other corporate booths was that of the Spanish Association of parts Torneadas ADECEN,

The 2006 Edition will take place from Nov. 29 2 Dec 2006.