Future does not take us off guard

"Steffen Kinkel, responsible for" Industry and Service Innovation "at the Fraunhofer Institute for systems research and innovation ISI, in Karlsruhe, comments on the German machine tool industry."In Germany, most of the industry lies in the hands of medium-sized enterprises. These companies don't have the necessary methods or the information needed to draw up technological plans in the long term. "Now and increasingly, these SMEs are beginning to appreciate the effects of the distance between the shorter product life cycles and the necessary longer periods for more sophisticated products."

One way out of this dilemma is to apply technology in the long term and product planning. In the project "Machine Tool Initiative 20XX", institutes like Fraunhofer ISI and Heinz Nixdorf Institute (HNIS), Paderborn, they help to SMEs through methodological assistance and useful information.

Guido Stollt, HNIS, says the following: "In the seminars that we have maintained with manufacturers and users of machine tool we have developed various scenarios for the future of the market for the industry and business development, to which providers would like to adjust." These scenarios are based on a network of influential factors. "For each factor shall be considered development courses, also known as projections".

Technical scenario means thinking beyond the future, not predict the future. A breakthrough interesting within this project "Machine tool initiative 20xx" is the connection of this technique that we could call "on stage" with a study of Delphi conducted by Steffen Kinkel and other ISI members, carried out a follow-up of individual screeningsasking industry experts what thought about it. According to Steffen Kinkel, "the Delphi method is a two-phase process whereby collected surveys are forwarded to experts a second time." "In this way can reconsider their original answers and correct them if necessary".

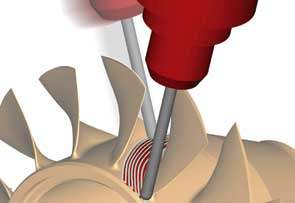

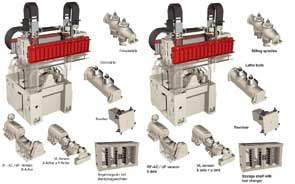

The results of the survey are interesting and important for the work of future manufacturers and users of machine tools. For example, it shows that four of the six most likely opportunities for the German machine tool industry are based on technological developments. According to experts, it is highly probable that in the near future, 30 per cent of machine tools will integrate self-monitoring, predicting failures and tele-servicio functions. Also, using large scale production systems will "plug-and-produce" soon. These machines allow the rapid Assembly of complex systems from simple modules. With an average of 55% likely, experts consider systems micro-electromecánicos as active components (e.g. active mooring systems) to fight the market within ten or fifteen years.

Two of the developments that are considered highly likely can be characterized as defined risks, which can even occur during the next five years. On the one hand, the experts consider that, in the future, the relationship-based management will be the turning point for the sale of machine-tool, because the technical characteristics objective will be virtually identical in all the competition. An evolution of these features will be a serious danger to exports of German industry of machine tools, whose success is based on the excellent technical quality of their products, rather than relations closed or short distances with your international customers.

Guido Stollt stressed the high degree of agreement among the experts of the Delphi study: "nearly 75 per cent of the claims of the study are classified as important for the industry, according to experts." The conclusions are interlinked closely with predictions, it is fair to assume that the scenarios will also be a general agreement with the industry. "The results of the two projects were presented at the EMO exhibition, and also explained the importance of interconnections"

The data obtained during the development of scenarios and the Delphi survey are processed and deposited in a knowledge base. Together with a guide that describes the development of the scenarios from draw databases; This provides an easy tool to use to support a strategic plan in SMEs. This guide and knowledge base is available to other companies in the industry. SME key, this is a proven pragmatic tool for forecasting and develop strategies.

Showcase of innovations

Carl Martin Welcker, President of VDW, welcomes this project: "As well as the evolution in the process of innovation that is being developed in companies in their daily work, we also need a breath of fresh air for a revolutionary leap in technological development." For that purpose, the industry carries out research projects such as 'New machine tools for the production of tomorrow'. "It is very encouraging that the policy of government research has recognized this as a crucial issue for the role of Germany as a major producer in the world."

Joint projects presented at the Symposium allowed to develop an extensive investigation. In 2001 and 2002, the VDW Association, in collaboration with WPG, the German Academic Society for Production Technology, and the Industrial Association for Production Technology, conducted a pilot study on the theme "The 2010 machine". As a result, the main priority was assigned to the need to develop peripheral components and machine tools that increase flexibility. Here arose the competition: "New machine tools for the production of tomorrow".

Sketches received in response to this call for proposals, will chose the best twelve projects to receive funding. They are altogether eighty companies, including machine tool manufacturers, suppliers of components, universities and institutes, which are related to these projects. "" At the Symposium "Machine tool of high performance for the production of tomorrow", presented its first results - divided into five thematic sections: "The future of machine tools", "Micromecanizado machining and precision", "Simulation and optimization", "Modularization" and "Automation".

Carl Martin Welcker also found interesting meetings and projects: "Putting consumers/users in contact with manufacturers, are able to develop points of view fundamental systems of machine-tool of the future". "I know for sure that the results of individual projects will not have an impact on those who will be tomorrow."