In the 2006 BIEMH Tekniker

The scope of application of this new technology is very promising, and covers advanced machine tools and, by extension, any machinery to move and position accurately subject to manufacturing and assembling parts or elements.

Thus, they are conceivable contributions to the machine of machining of high precision (by elimination of the accumulated errors in conventional mechanical systems), on the border, it could be acted entirely by magnetic fields (header, table and cars). Equally encouraging is the field of application in management systems for parts that require clean environments or in vacuum.

The emplo of lasers in manufacturing

As advance what Tekniker will be able to perform in the future, this fair presents a nd: YAG of 2,200 W of power laser head enabling the Centre to trying different processes of input (especially "laser cladding") piece,(welding, temple and, eventually, rapid prototyping).

The "laser cladding" is a technique of contribution, used especially in repair and in the lining of moulds and dies that, with this device, is carried out using optical fiber of 300 or 600 µm and supply of powder nozzles, so that the cord of material has a width of between 0.5 and 2 mm.

The complete cycle of micro-manufacturing

To do this, it has a valuable knowledge accumulated in recent years, as well as a leading micro-machining and microinjection equipment. At the fair is to put the emphasis precisely on this final step of the process of micro-fabrication and therefore is going to expose the "battenfeld" microinyectora making preserial short of the dental "brackets" which are produced for the Euroortodoncia client.

The "Battenfeld" is capable of injecting plastic parts between 0.001-0.01 g, with a maximum volume of 1.1 cm3 material and a time for standard cycle of 5 s. In addition, this team also allows making processes MIM (Metal Injection Moulding) and PIM (Powder Injection Moulding), although in these cases the injection should follow you the desbanderizado and the sintered.

Ambient intelligence in the field of the production company and services

In particular will be shown how operators can access, through spoken interface, gloves, goggles for protection and other consumables, in a controlled way (radio frequency identification, using TAGs, or sensor networks) and automated.

In addition to the industrial example, also more basic advances in the sensing of elements of the clothing of the workers will be displayed. It is the case of the gloves, equipped with the relevant sensors, can identify the object that is manipulating, which in turn enables the system to provide information concerning the same, without even the human being so requests.

Recent advances in the field of PVD coatings

The BIEMH has been the place where will show recent accomplishments in surface micro and nano structured, order tribológica, as well as the achievement of coatings with very good adhesion on difficult substrates (highlighting the permanent advances in the lining of plastic materials)(, especially to replace some highly polluting traditional processes).

His stand also welcomes the offer of the "spin off" Tekniker "millennium coatings", after attending fairs of as much significance as the EMO exhibition in Hannover or Cevisama, deployed in the BIEMH its wide range of cameras PVD. It stands out as the most innovative, the MIDAS 775, of considerable dimensions, and includes the new evaporators of own development and benefits superior to the State of the art.

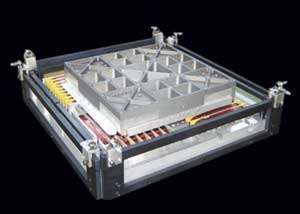

Lightweight application in machine tool glued structures

In this fair Tekniker shows a pair of glued structures that have resulted from the work carried out in the wine project, and which have already been built and tested on one of our prototypes (case of the milling of high speed "bizkor").