Tecnocim in the 2006 BIEMH

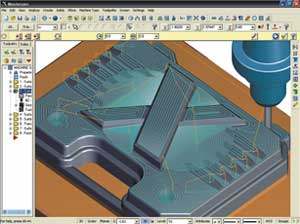

In addition to the new Windows interface and new features in design, it also presents the new features in 3D machining which have been incorporated into the MR1 release, these new strategies are grouped into a single main option, which is separated in roughing and finishingeach of them also includes sub. The main advantages of the new system are: to move a roughing operation to one of finish without having to reassign geometry and taking advantage of all the technological parameters.

The improvement of efficiency in the trajectories of roughing generated, same piece, calculated with Mastercam V. 9 takes 2 HR 39 min in machining her, with MR1 with the same cutting conditions, the paths are more efficient and reduce time of machining, the order of 40 per cent.

Trajectories of finish are also more optimized for high speed machining technique.

Another aspect to be highlighted in Mastercam X v. are the improvements in the machining of STL models directly, without need to generate surfaces. You can now combine STL models with models of surfaces or solids and generate the trajectories of roughing and finishing. The learned paths are milder that in previous versions and the time of calculation much more reducid

Tecnocim enters the sector of PLM solutions

Windchill is a system designed for:

• Control all digital information of the company.

• Manage the processes of change on a product or service.

• Facilitate collaboration between different departments of the company or between the company and its clients / suppliers.

• Plan and manage the various projects of the company.

New version of the products Topsolid 2006

Topsolid: New function for mixing image (bitmap) files with vector files, this function is very interesting to prepare presentations of products that combine technical design with environments from photography or logos, etc.

Enhance the functions of kinematics, with detection of collisions, limits, etc.

Functions for the deployed complex pieces of sheet metal:

• Automatic kinematics of the movement of the mold, is not necessary to define the elements.

• New function to create the wells of cooling.

• Topprogres: New module to display the tensions of the pieces of sheet a time made the drawing.

New version of the Predator software

The only way to ensure the absence of collisions and tours outside boundaries of the machine.

New software for programming of robots

Robotmaster, carries out the programs of robots Fanuc, Kuka and ABB through the simulation of the movement in the 6-axis and can make amendments to the initial positions to achieve greater effectiveness and to avoid exceeding the limits of the axes.

Robotmaster has been developed in Canada and works in combination with Mastercam