The current society demands new designs that adapt to his needs

New containers for the alimentary industry

Ruth Jovani, researcher of the Technological Institute of the Packaging, Transport and Logistical (

The food and the container are an indivisible couple. The feeding is a primary need and, therefore, the consumption of this type of goods no decrece, rather modifies . That's why in this moment of change the market of the feeding has to bet by new products that cover and adapt to the current needs.

The current society, with new habits of consumption, requires of new designs that adapt to his needs. The rhythm of life reduces the frequency with which realizar the shopping, reason that demands containers that conserve the product during a period of greater time. Besides, because of the little availability to realizar the purchase, extends increasingly the service of on-line purchase and distribution to domicile.

Have of little time to eat or to prepare a dish elaborated, demand increasingly containers that allow to cook and eat in the same container. Enjoy of a dish elaborated comfortably, without need to realizar changes from the container to a container to cook and afterwards to a dish to consume.

But no only this is important. In these moments in which the half purchasing power has reduced , the habit to eat was has turned into a problem for a lot of consumers. This sector of the population is accustomed to a recently cooked dish, of a quality that until the moment was difficult to reach with the dishes precooked products. In a lot of cases because of the structure or material of the container that do not help to keep the properties that characterise to the product. In other cases, had to that the container does not adapt to the method of cooked of the that has .

The independence of a source of feeding or of a system to be able to heat or cool a drink, is one of the advantages that will be able to offer the new containers.

In a lot of cases the main difference between products roots in the container, east can turn into the only reason by which chooses a concrete commercial mark. Like example, a container with a system that inhibits during a period of greater time the oxidation. This offers a product of greater quality during more time, avoiding losses of product and reducing unnecessary scraps.

The need of change does not come demanded only by the consumers. The own envasadores and manufacturers of containers, need to know the changes and new tendencies in the productive and logistical system, to offer tangible values to a competitive price. One of the aims of a lot of envasadores is to reduce the unitary cost. This aim will be able to reach if the technology applied to develop this container allows the reduction of material, the application of other materials or the optimisation by means of a new design.

Increase the scope of the chain of distribution, allows the extension of markets. This change demands to study the risks of the distribution: vibration, dynamic compressesion, humidity, temperature. The requirements of the new markets and the need to fulfil with the valid legislation related with the sustainability, suppose new challenges for the design of the container.

Tendencies

The tendencies of these last years are focalizadas in improving the containers of products of basic need, like the feeding.

Inside this typology of products, the sector of the ready dishes stands out like one of the most promising of the feeding in Spain. In the sector of the dishes prepared the two groups with greater market are the dishes refrigerated and dishes frozen products. The market of the dishes refrigerated generates around 700 million annual euros, with available volumes around the 150.000 tonnes. By what does reference to the dishes frozen products, the majority of the estimates indicates a level of sales around 144.000 annual tonnes (1).

Therefore, in this sector appears the opportunity to improve the current systems, resolving the lacks detected to level of the consumer and of the envasador. To analyse the position in which it finds the alimentary container to day of today, splits of the main functions of the conventional container, presented to the start of this article and that basically are to contain, conserve and protect the integrity of the product, and inform and sell the product contained.

To. Contain the product

Initially, the function to contain an alimentary product finished in the moment in which the product cooked and consumed . The function was merely contain the product, to temperature acclimatise or refrigerated. Now, contain the product can mean in some cases bear the temperatures of freezing, since many of the products distribute frozen products. In the majority of products precooked products his introduction in the microwaves or in the oven, without that this cause an alteration of the container that can affect to the product is a request.

Once cooked appears a new function: contain the product while it consumes exerting of dish.

The definition to contain the product keeps on being hit, but increasingly, cover this function supposes a process of improvement of the container. In a lot of cases the solution is in a combination of different materials that achieve the properties wished.

To.1. Materials esterilizables

Of the same way that the glass allowed the sterilisation in the own container, the companies of containers of plastic explain years afterwards with the combination of polymeric materials, that allows to realizar the thermal sensors treatments in the own container. An example of this type of material is a compound laminado of PP/EVOH/PP.

To.2. Containers microondeables

The development of new multilayered materials allows that the consumer enter the container in the microwaves without that produce a migration from the container to the product. Examples of structures used for this type of containers are PP/EVOH/PP or PET/To the/PP (2). The PP is used to to use because it presents some desirable characteristics, like resistance to the sorción of the fat, is esterilizable and microondeable.

To.3. Containers horneables

No only the introduction of the container in the microwaves has been an advance. Generate material that bear the temperatures of the oven keeping the properties of the container, or even allow his cooking in both, has been and keeps on being a challenge for the manufacturers of packaging. The main aim of these flexible or rigid containers, is to resist high temperatures during a determinate time. At present they exist some commercial solutions no only for dishes precooked products, but also for products of panificación.

B. Conserve and protect the quality and the integrity of the product

Initially this protection of the product remitted to fulfil functions more general, like avoiding the spill of the product during the transport, prevent the exchange of gases between the interior and the outside of the container or bear the possible derivative risks of the cycle of distribution. At present, these properties consider covered by any system of packaging, by what the challenge is in the active participation of the container in the protection of the product.

An active container has like function prolong the useful life or improve the state of the foods packed, by means of the incorporation of substances with some beneficial properties or the elimination of other that they can present problems for the conservation. The base of these mechanisms is a transport of masses that includes a regulation of the permeación of gases in the space head, a retention of substances by sorción (3).

This sector of the market predicts an increase in his volume of sales, that will see reflected especially in the absorbers of humidity, kidnappers of Or2 and CO2 and containers microondeables (4).

B.1. Active containers or containers realizar with material barrier for the control of the oxidation

The oxidation of the food is a reaction initiated by free radicals. This type of reactions, once initiated progress very quickly, hampering increasingly his control and deteriorating the food. To retard the initiation of the oxidation use different mechanisms.

For the control of the oxidation can act of two ways. Can act on the Or2 or on the species that can react with him. The control of the first achieves deleting the Or2 residual of the space head of the container and/or avoiding the entrance of Or2 from the outside. On the other hand, the control of the reactive species in front of the Or2 can reach with the addition of antioxidants in any of the elements of the system product-container.

The use of material barrier avoids the entrance of the Or2. Usually to act like barrier chooses a laminado multilayered. With this achieves a low permeability to the different gases and a high mechanical resistance to avoid a possible punción. Two laminados multilayered common, that act like barrier are PA/PVdC/PE (5) and PA/EVOH/PP. The layer of PA allows the impressesion. The central layer acts like barrier. And the inner has to allow the termosoldadura. The barquetas of food precocinada and sobres for products dehydrated, are examples of containers that use this multilayered material.

The second option to reduce the quantity of Or2 in the space head of the containers are the kidnappers of Or2. These kidnappers of Or2 they can deposit in the material of the container or in the one of the closing. Examples of kidnappers are metals and metallic oxides, sour ascórbico or enzymes. These compounds tend to oxidarse with greater ease that the food contained, and therefore use the Or2 existent, avoiding that it remain available.

The main problem is that the majority of the kidnappers of Or2 they can not go in in direct contact with the food. Therefore, it is function of the design of the container separate physically this element of the product, but at the same time, allow the interaction of the kidnapper with the Or2 existent in the space head.

The containers active with antioxidant agents they can exert an action of protection on food contained, reducing the reactive species of the Or2. Examples of antioxidants applied to the material of container are the vitamin E, that help to reduce the effects of the oxidation.

Proofs in containers with different laminados barrier for loncheados.

B.2. Active containers for the control of the CO2

Many of the foods that commercialise packagings generate CO2. The fruit and vegetables, by his nature, consume Or2 and they generate carbon dioxide. The products toasted, like the coffee, once packagings follow giving off CO2. To control this broadcast use substances like the hydroxide of calcium.

On the other hand, it exists another range of products that by his high humidity once packagings, require the use of CO2 like fungicidas. Products horneados, cool meat or cheeses, are some of the products that require of emisores of CO2 to control the microbial growth. Examples of compound emisores of CO2 they are the calcic bicarbonate and the acid ascórbico.

C. Present and identify the product

This function engloba the function to inform and the function to sell the product. The first, offer information to the consumer, requires of an enlargement to inform to any member of the chain of distribution on the state of the product. The way to offer this information bases in new technologies, like the labels RFID or the indicators; included elements inside the definition of intelligent containers.

C.1. Intelligent containers

An intelligent container is that that no only protects the content, but it interacts with him: obtaining information of the product or of his surroundings. This information processes and presents to the consumer.

Many of the intelligent containers for products of feeding are based in substances indicadoras, that is to say, substances that inform of the state in which it finds a product. A good example are the indicators of freshness, that reveal the quality of the product packed through his answer in front of any of the changes that suceden in the food. This small sensor reacts with the gases generated by the product during the reaction of oxidation, and changes his initial state (generally changes of colour) to inform of the change in the product. indicators termocrómicos or of humidity are others of the possibilities that offer the intelligent containers.

The second, present and sell the product, turns into to adapt the products to the taste of the consumer. A consumer that increasingly demands new functions that achieve a smart product to consume. Perhaps, this is one of the most complex functions inside the definition of container, and surely one of which goes to mark tendencies of market and challenges of investigation during the next years.

C.2. Containers with susceptores of microwaves

The concept of susceptor for microwaves is not new, since it comes using from the years 80. The function of this element is to absorb the radiations microwaves and turn them into heat. Generally the susceptores are realizar in aluminium. By his condition of metallic material is able to absorb the microwaves that generate a flow of swings inside the material. Vibrations that turn into heat. In this way, a fine layer of aluminium that can laminarse beside the material of container or be deposited by metalización to the empty, works like source of heat. This source of heat situated in strategic zones of the container, can generate an effect of toasted associated generally to the oven. The temperature that can reach in the interior of a container with susceptor is around the 200 °C.

And if in addition to allowing a very similar cooking to the horneado, the container plays an active paper on the product?

At present already they exist the first commercial solutions with susceptores that have an active element. These elements absorb the excess of humidity or excess of oil during the cooking, without seeing affected by the temperature reached in the container.

C.3. Containers microondeables with valve to cook to the steam

This technology allows to cook the food to the steam inside the own container. With this system achieves a lower loss of humidity, that avoids that reseque the food and keeps better the vitamins. The technology used is the perforación by laser or imperfection controlled of sewings, that work like valve of leakage. When arriving to one some pressesure and temperature the steam can be freed. This type of cooking applies at present to products like frozen fish products and vegetables.

C.4. Containers autocalentables

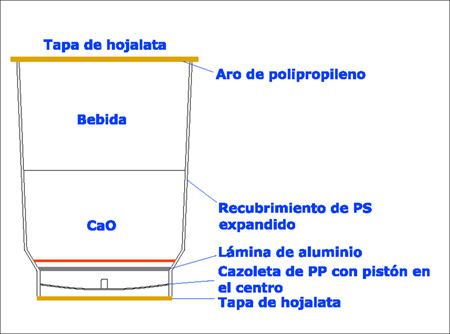

The containers autocalentables base in a reaction that generates heat to increase the temperature of the product, an exothermic reaction in which they participate different reagents depending of the heat that wishes reach. A very used reaction is the hydratation of the oxide of calcium (CaO) with water in which they participate economic reagents. Besides, the products or by-products generated are acceptable medioambientalmente. In the actuality one of the markets that has included this technology is the one of the hot beverages. The base of the operation of this type of containers is, keep separated the reagents until the moment in which it goes to consume the product. By this reason, all the systems autocalentables consist of volumes herméticamente separated to house the drink, the oxide of calcium and the water. The design of this type of containers allows to mix of form homogénea the two reagents and strength to that these wrap the busy volume by the product. In this type of beverages achieves an increase of the temperature around 40 °C above the initial.

Section of a container autocalentable for beverages.

D. Facilitate the transport and the commercial distribution

This function has been studied during years by different centres of investigation, that work beside the companies for the development of new systems of packaging.

Conclusion

In definite, the new tendencies in the sector of the alimentary container decant by containers that exert some active function on the system pack-product, since thanks to these compounds reduces the volume of cool foods refused. The preferences of the companies base in the optimisation in the cycle of distribution. And every time more, the consumer it decants by a container that contribute a new function as the one who offer the systems autocalentables.

- Consumption and cost of ready dishes in Spain. Source: Ministry of Environingingment, Half Rural and Marino.

- PP: polipropileno, EVOH: copolymer etileno alcohol vinílico, PET: polyester, To the: Aluminium

- Regulation (CE) No 450/2009 of the Commission of 29 May 2009 on materials and active and intelligent objects allocated to go in in contact with foods.

- Pira international Ltd (2009) The Future of Packaging: Long-term Scenarios to 2020.

- PVdC: policloruro Of vinilideno.

- Codex Alimentarius: payment recognised internationally of standards and codes of relative practices to the foods, his production and alimentary hygiene whose aim is the protection of the consumer.